Groove face machining device and groove face positioning method for large ship

A processing device and ship technology, applied in the field of industrial manufacturing, can solve problems such as high cost, low efficiency, and complicated processing process, and achieve the effect of solving cutting processing problems and ensuring flatness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

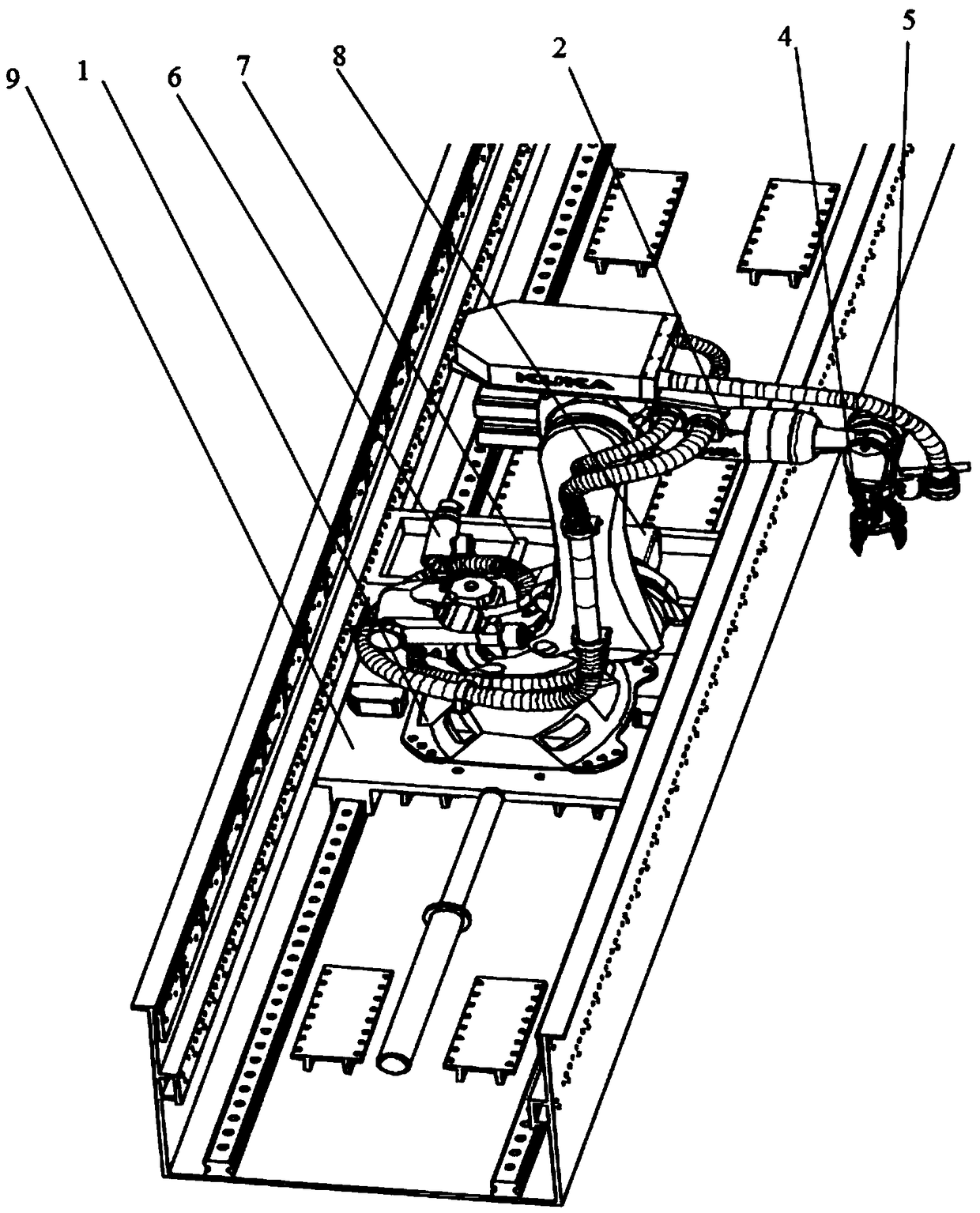

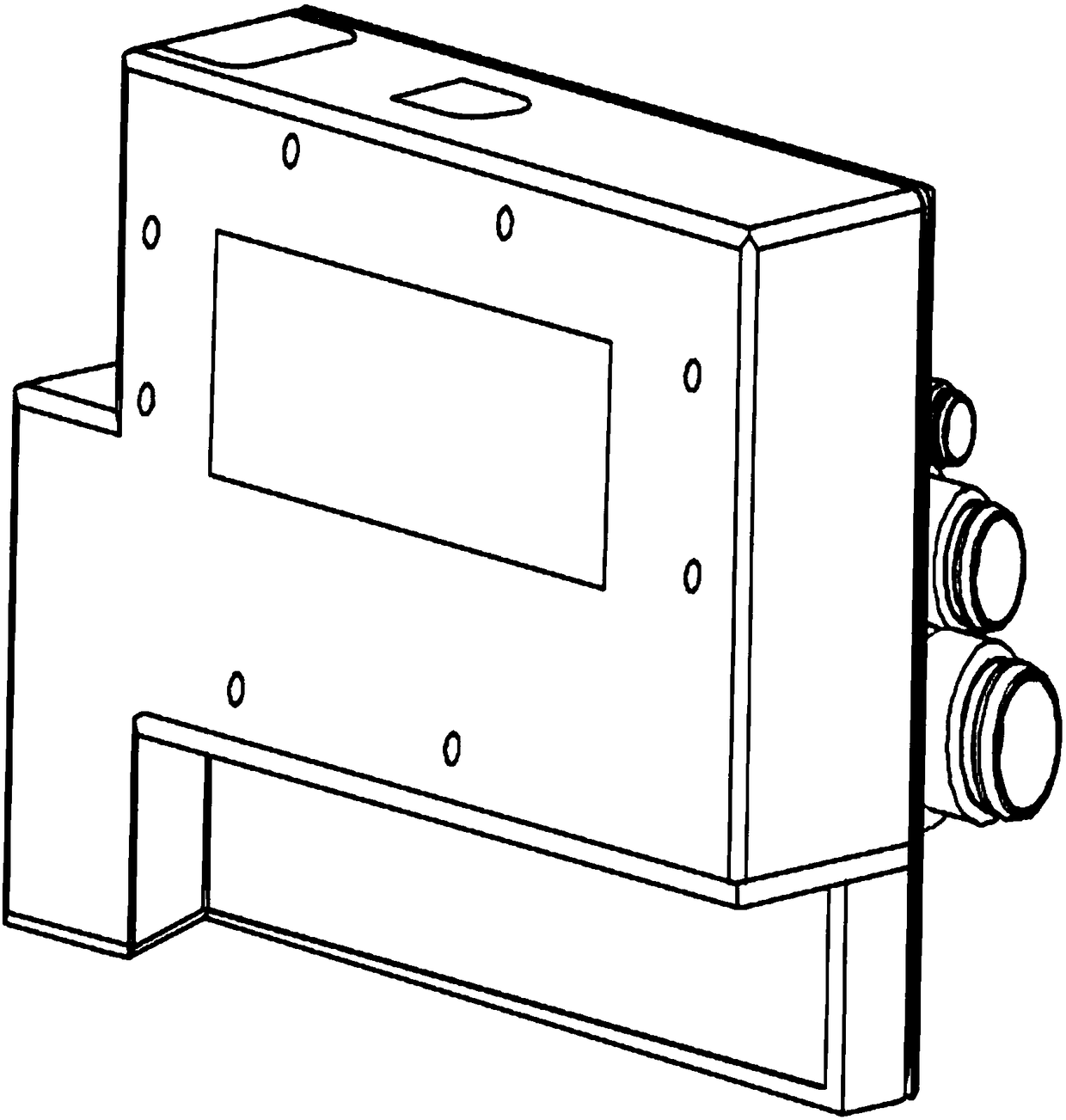

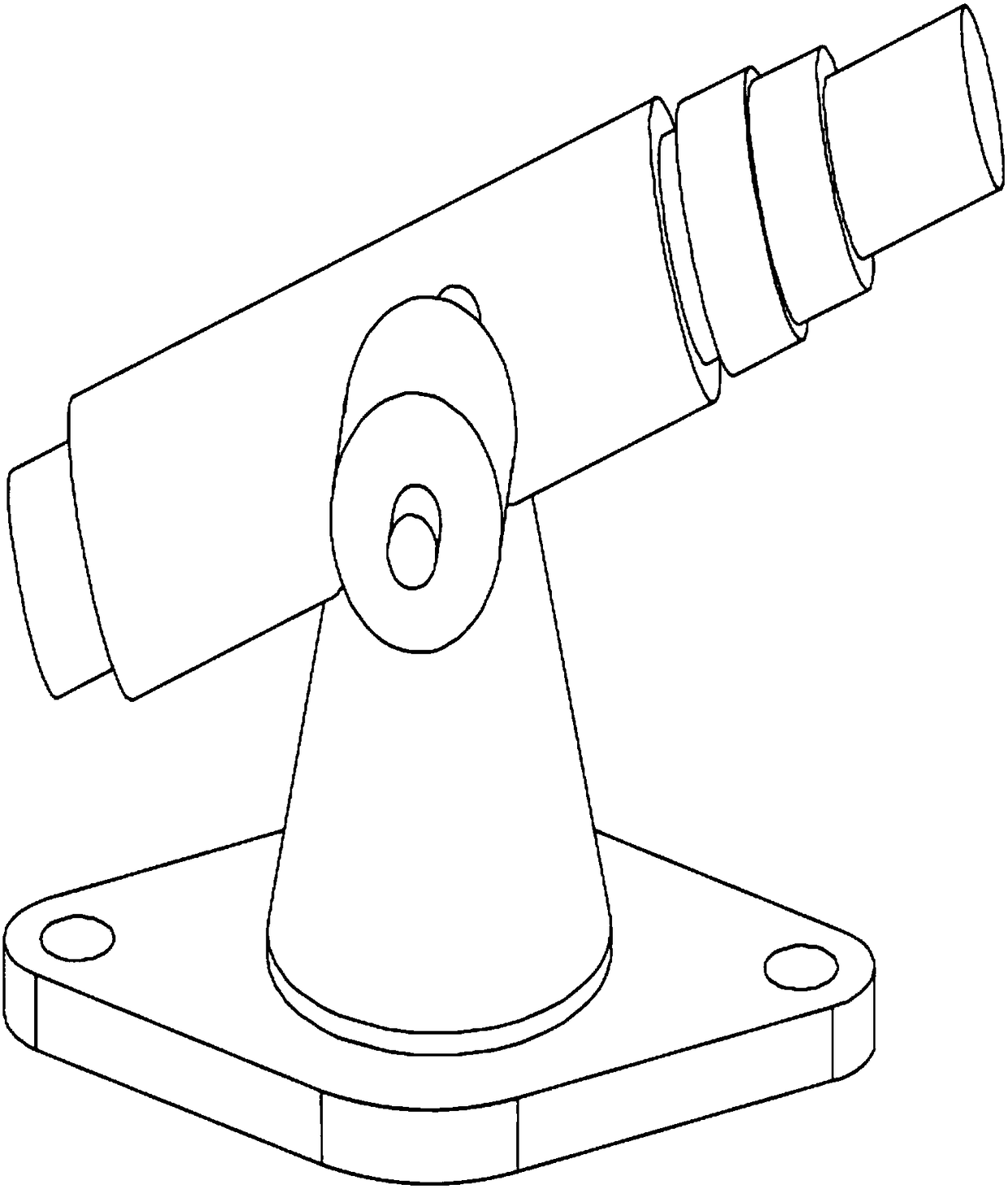

[0027] like figure 1 , figure 2 and image 3 As shown, a large-scale ship groove surface processing device provided in this embodiment includes a mobile platform 9 arranged on the ship groove surface and sliding on it, and a six-axis articulated industrial robot milling machine set on the mobile platform 9 device and workpiece; the milling device of the six-axis articulated industrial robot includes a six-axis articulated serial industrial robot 1, and a high-speed electric spindle 2, a probe 4 and a laser set at the end of the six-axis articulated serial industrial robot 1 Sensor 5; the processing workpiece includes a milling workpiece 6, a laser scribing workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com