Rotary tool-feeding cutting mechanism for lathe

A technology of cutting mechanism and rotary feed, which is applied to metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of high processing efficiency, safety and reliability, low processing and manufacturing costs, and achieve low manufacturing costs, High processing efficiency, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

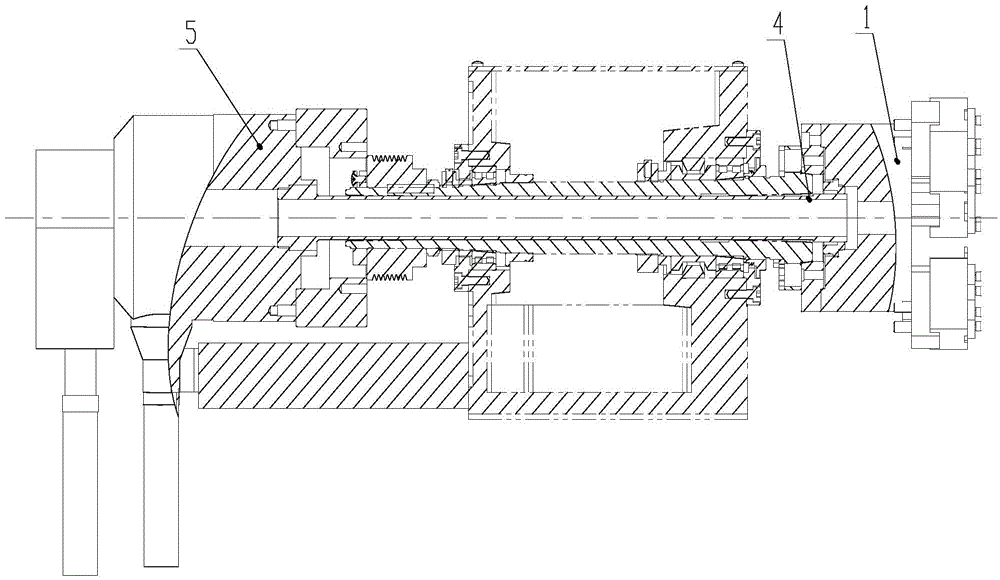

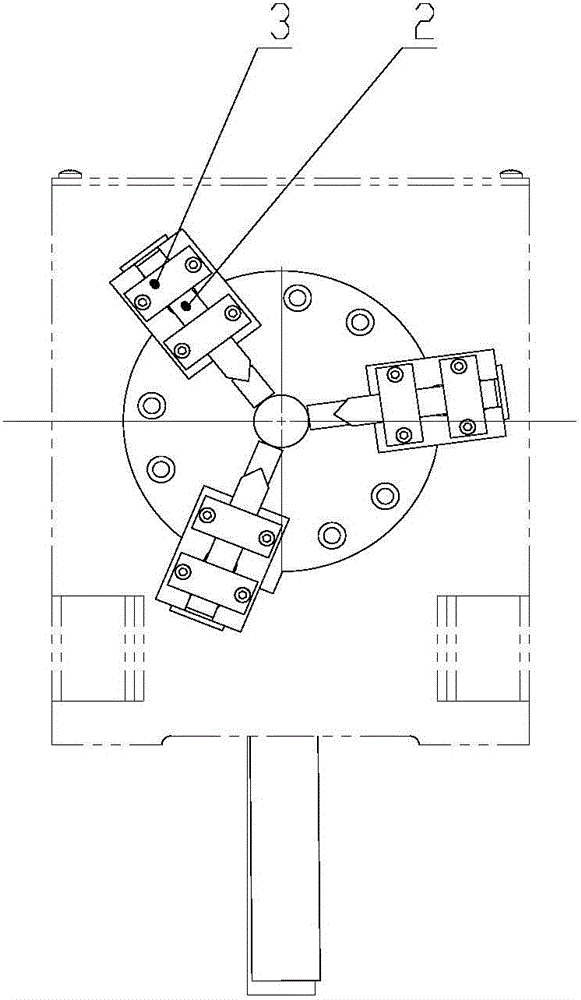

[0017] Embodiment 1: A rotary feed cutting mechanism for a lathe, including a control mechanism, the control mechanism is connected to a power unit 5, and the power unit 5 is connected to the chuck 1 through a connecting rod 4, and the chuck 1 of the chuck 1 The claw is provided with a cutting mechanism; the control mechanism includes a foot switch and a solenoid valve, the foot switch is connected to the solenoid valve, and the solenoid valve is connected to the power device; the power device 5 is a rotary cylinder; the cutting mechanism includes three The tool 2 located on the same plane, the tool 2 is installed on the claw of the chuck 1 through the pressing blade 3; the chuck 1 is a pneumatic chuck.

Embodiment 2

[0018] Embodiment 2: A rotary feed cutting mechanism for a lathe, including a control mechanism, the control mechanism is connected to the power unit 5, the power unit 5 is connected to the chuck 1 through the connecting rod 4, and the chuck 1 of the chuck 1 The claw is provided with a cutting mechanism; the control mechanism includes a foot switch and a solenoid valve, the foot switch is connected to the solenoid valve, and the solenoid valve is connected to the power device; the power device 5 is a rotary oil cylinder; the cutting mechanism includes three The tool 2 is located on the same plane, and the tool 2 is installed on the claw of the chuck 1 through the pressing blade 3; the chuck 1 is a hydraulic chuck.

[0019] When the present invention is used to cut the workpiece, the chuck 1 is first in the open position, and the claws on the chuck 1 drive the tool 2 to move outward together. After the workpiece moves to the processing position of the claws, step on the foot swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com