Engine crankcase coarse positioning fixture and positioning method thereof

A crankcase and engine technology, which is applied in the field of manufacturing and processing of auto parts products, can solve problems such as shaking of the workpiece, poor process reference size, and affecting the processing quality of the crankcase, so as to achieve accurate and reliable positioning and meet the processing accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

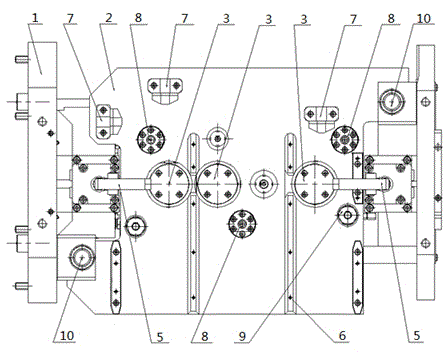

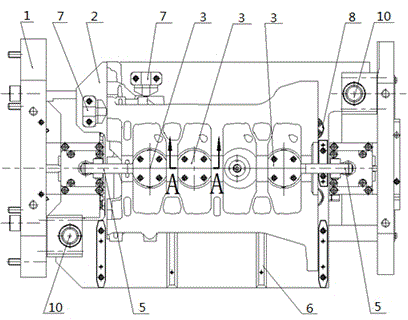

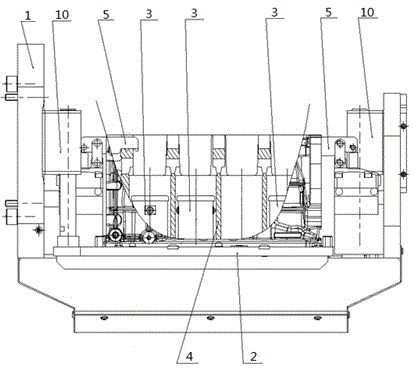

[0027] Such as Figure 1 to Figure 3 The rough positioning jig for the crankcase of the engine shown includes a frame 1 , a bottom plate 2 and three expansion pin assemblies 3 . The base plate 2 is mounted on the frame 1 so as to be movable up and down through a driving device 10, and the driving device 10 in this embodiment is a hydraulic cylinder. Clamping jaws 5 that can move up and down are respectively arranged on both sides of the frame 1 . A slide rail 6 and a positioning member are arranged on the bottom plate, and the positioning member includes a plurality of limit blocks 7 and flat-headed positioning pins 8 corresponding to the positions of the positioning holes on the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com