Servo autotracking support for bent axle grinding

An automatic tracking and support device technology, which is applied in the direction of grinding workpiece supports, machine tools designed for grinding workpiece rotating surfaces, grinding/polishing equipment, etc., can solve the influence of support rigidity and working stability pulsation, and is not suitable for fixing Adjustable center frame, expensive imports and other issues, to achieve the effect of improving the overall grade and value, high centering accuracy, and improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

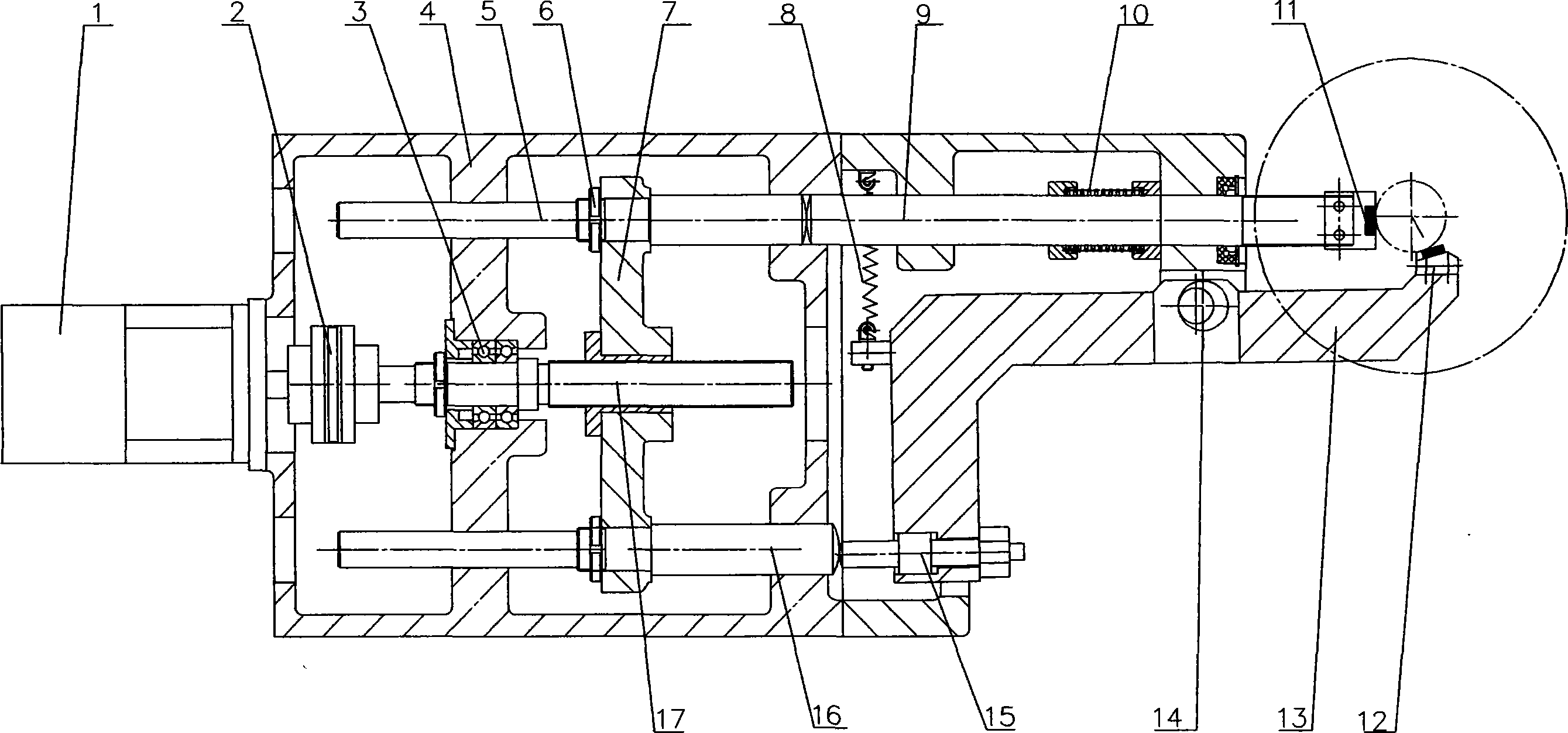

[0019] Referring to the accompanying drawings, a ball screw 17 is installed on the box body 4 through a screw bearing 3, and a servo motor 1 is installed on the box body 4, and the servo motor 1 is connected with the ball screw 17 through a coupling 2 without clearance. The ball screw 17 is set with the drive link 7, and the upper drive rod 5 and the lower drive rod 16 are slidably installed on the box body 4, and the upper drive rod 5 and the lower drive rod 16 are fixedly connected with the drive link 7 through the lock nut 6 , the upper support arm 9 with the first return spring 10 is slidably installed on the box body 4, one end of the upper support arm 9 is correspondingly driven with the upper drive rod 5, and the other end is provided with an upper support alloy 11, which passes on the box body 4 The adjustable eccentric shaft 14 is equipped with a lower support arm 13 with a second return spring 8, one end of the lower support arm 13 is provided with an adjustable push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com