Central connected periodic structure-based textile product and preparation and application methods there

A periodic structure and textile technology, applied in the decoration of textiles, textiles and papermaking, textiles, etc., can solve the problems that solid-shaped structures are not suitable for low-frequency resonance points, resonance frequency differences, and affect practical performance, etc., to achieve good breathability and wearability The effect of comfortable performance, large size and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

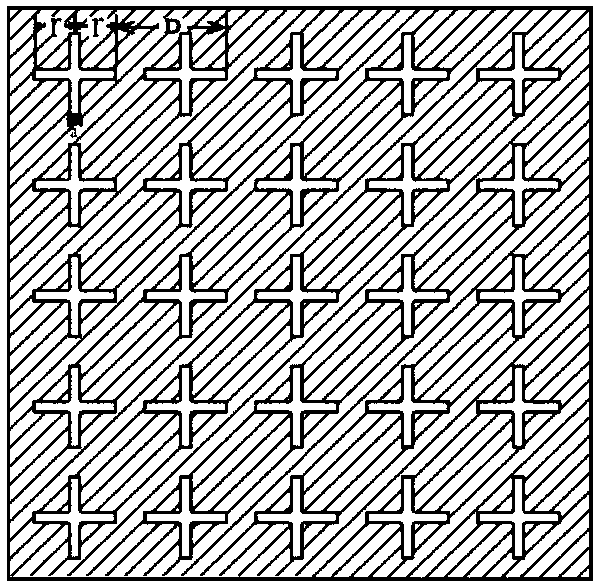

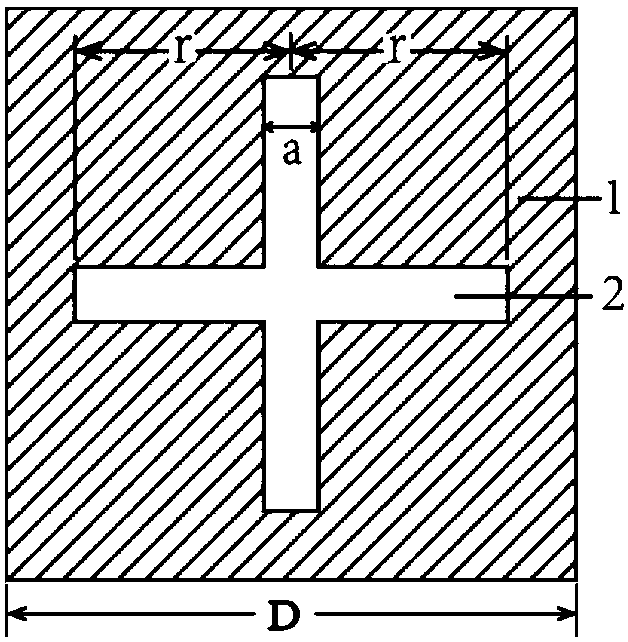

[0040] Example 1: Using ordinary polyester / cotton 50 / 50 fabric as the base material, the warp and weft yarn count is 144dtex×144dtex, the warp and weft density is 330×260 / 10cm, and the square meter weight is 210g / m 2 . The cross-shaped periodic structural unit shown in Fig. 2(a) is adopted, and the dimensions are D=144mm, r=70mm, a=8mm. According to the structure and size, the cross-shaped periodic structural units are closely arranged to prepare a circular net with a size of 92cm×150cm, wherein the conductive part is the leakage part. Using conductive silver paste, the conductivity is 6.10×10 7 S / m, the conductive silver paste is printed on the polyester / cotton substrate through a rotary screen, and dried at 180°C to obtain a cross-shaped periodic structure textile printed with conductive areas and non-conductive areas. The resonance point of the textile is 0.9-1.0GHz, and the reflection coefficient at the resonance point is -32.58dB, such as image 3 shown. The textile is...

Embodiment 2

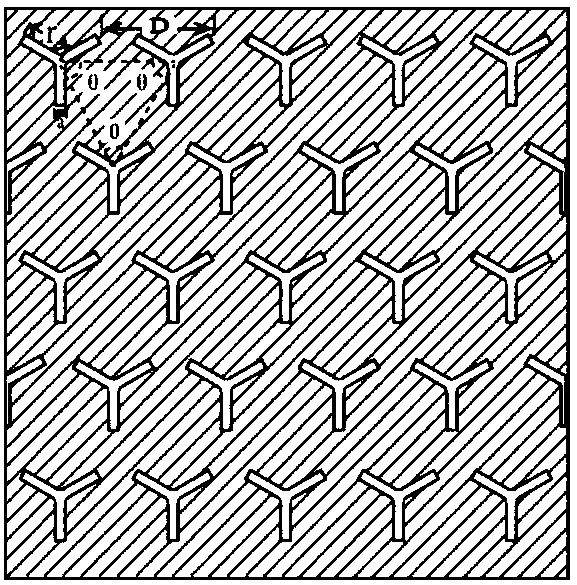

[0041] Embodiment 2: Based on the polyester conductive fabric coated with copper and nickel on the surface, the conductivity is 4.5×10 4 S / m, the warp and weft counts are 222dtex×222dtex, the warp and weft density is 486×325 / 10cm, and the weight is 190g / m 2 . On the laser cutting machine, the Y-shaped periodic structural unit shown in Figure 2(b) is used, and the size D=164mm; r=80mm; a=5mm. According to this size, the conductive fabric is cut to leave interconnected conductive areas and Y-shaped non-conductive areas, that is, to obtain textiles with conductive areas and non-conductive areas arranged in arrays. The resonance point of the textile is 0.9~1.0GHz, and the reflection coefficient at the resonance is -11.03dB, such as Figure 4 shown. The textile is cut and sewed, and a complete rectangular piece contains 15 Y-shaped periodic structural units in both the warp and weft directions to obtain curtains or wall decoration fabrics, which can pass the mobile phone communi...

Embodiment 3

[0042] Embodiment 3: With plain weave nylon fabric as the base material, the warp and weft yarn counts are 389dtex / 144f, the warp and weft density is 234×210 threads / 10cm, and the square meter weight is 197g / m 2 . The cross-shaped periodic structural unit shown in Fig. 2(a) is adopted, and the dimensions are D=74mm, r=36mm, a=8mm. The structure is engraved with a concave-convex pattern on the pressure roller of the hot stamping machine, and the convex part of the pressure roller pattern is consistent with the metal area in the structure. Select the commercially available bronzing paper, put its carrier film facing up, and the transfer layer is down to be close to the fabric base, using circular pressing, flat ironing, transfer printing process, in which the heating temperature is 170°C and the pressure is 8kg / cm 2 , hot stamping time 7s. Plating layer in bronzing paper (conductivity 4×10 6 S / m) is transferred to the textile according to the designed pattern, that is, a text...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com