Anti-cutting installation tool for blind hole rubber ring

A technology for installing tools and rubber rings, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problem that the sealing rubber ring is easy to be cut off, and achieve the effect of improving the installation method, facilitating the application of external force, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

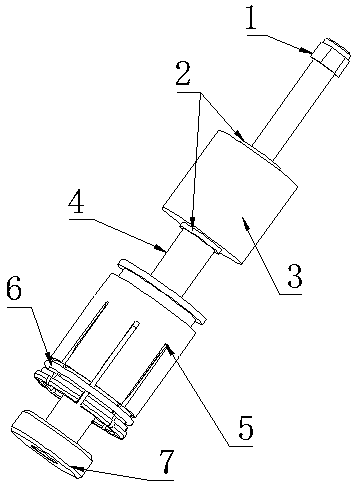

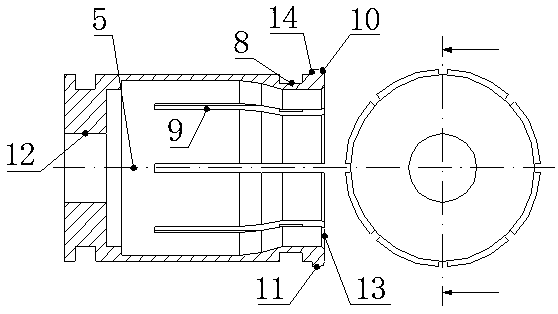

[0020] An anti-cut installation tool for blind hole rubber rings of the present invention comprises: a guide rod 4, a scaling mechanism 5, an elastic ring 6, and an expansion mandrel 7; the scaling mechanism 5 is cylindrical, and the lower part of the cylinder wall is axially provided with Groove 9, the lower end of the cylinder wall is provided with a step 11 and a radial ring groove 8; the zoom mechanism 5 is set on the lower section of the guide rod 4, the elastic ring 6 is installed in the ring groove 8, and the expansion mandrel 7 is fixed to the guide rod by thread Rod 4 lower ends.

[0021] The guide rod (4) is divided into upper and lower sections, the diameter of the upper section is smaller than that of the lower section, and the upper section of the guide rod (4) is provided with a booster mechanism (3); the end of the upper section of the guide rod (4) is provided with a limit nut (1) to limit the booster The stroke of the mechanism (3); the gasket 2 is installed a...

Embodiment 2

[0023] The present invention is an anti-cut installation tool for a rubber ring with blind holes, comprising: a guide rod 4, a scaling mechanism 5, an elastic ring 6, and an expansion mandrel 7; 3 cooperate to play a guiding role; the big end cooperates with the inner hole 12 of the scaling mechanism 5; The scaling mechanism 5 is cut and slotted at multiple places 9 in the horizontal direction, and the radial ring groove 8 is used. The horizontal slotting can realize the uniform shrinkage of the scaling mechanism 5 when it is stressed, and the elastic ring 6 is installed in the radial slot; the optical hole 12 at the upper end of the scaling mechanism 5 Cooperate with the guide rod 4; the root of the scaling mechanism 5 is processed with a rounding 10, which is convenient for passing through the sealing rubber ring;

Embodiment 3

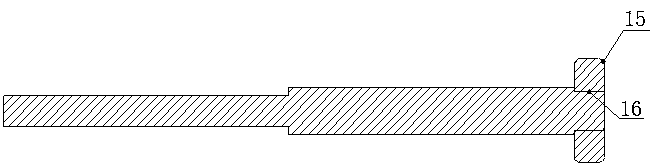

[0025] An anti-cutting installation tool for a rubber ring with blind holes in the present invention, comprising: a limit nut 1, a gasket 2, a force applying mechanism 3, a guide rod 4, a scaling mechanism 5, an elastic ring 6, an expansion mandrel 7; the elastic ring 6. The inner diameter is smaller than the outer diameter 8 of the radial groove when the scaling mechanism 5 is in the expanded state. The scaling mechanism 5 is in a shrinking state when no external force is applied, and the scaling mechanism 5 can expand when an external force is applied. The expansion mandrel 7 is fixed on the end of the guide rod 4 through the internal thread 16, and its outer diameter matches the inner diameter when the scaling mechanism 5 is expanded, and a rounding 15 is processed on the outer circle. to the guiding role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com