Electromagnet-type horizontal linear vibration motor and implementation method thereof

A horizontal linear, vibrating motor technology, applied in the direction of magnetic circuit shape/style/structure, reciprocating/swinging/vibrating magnetic circuit components, electrical components, etc., can solve the problem of small driving force, long response time, low utilization rate of magnetic field, etc. problems, to achieve the effect of maintaining vibration, fast response time, and avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

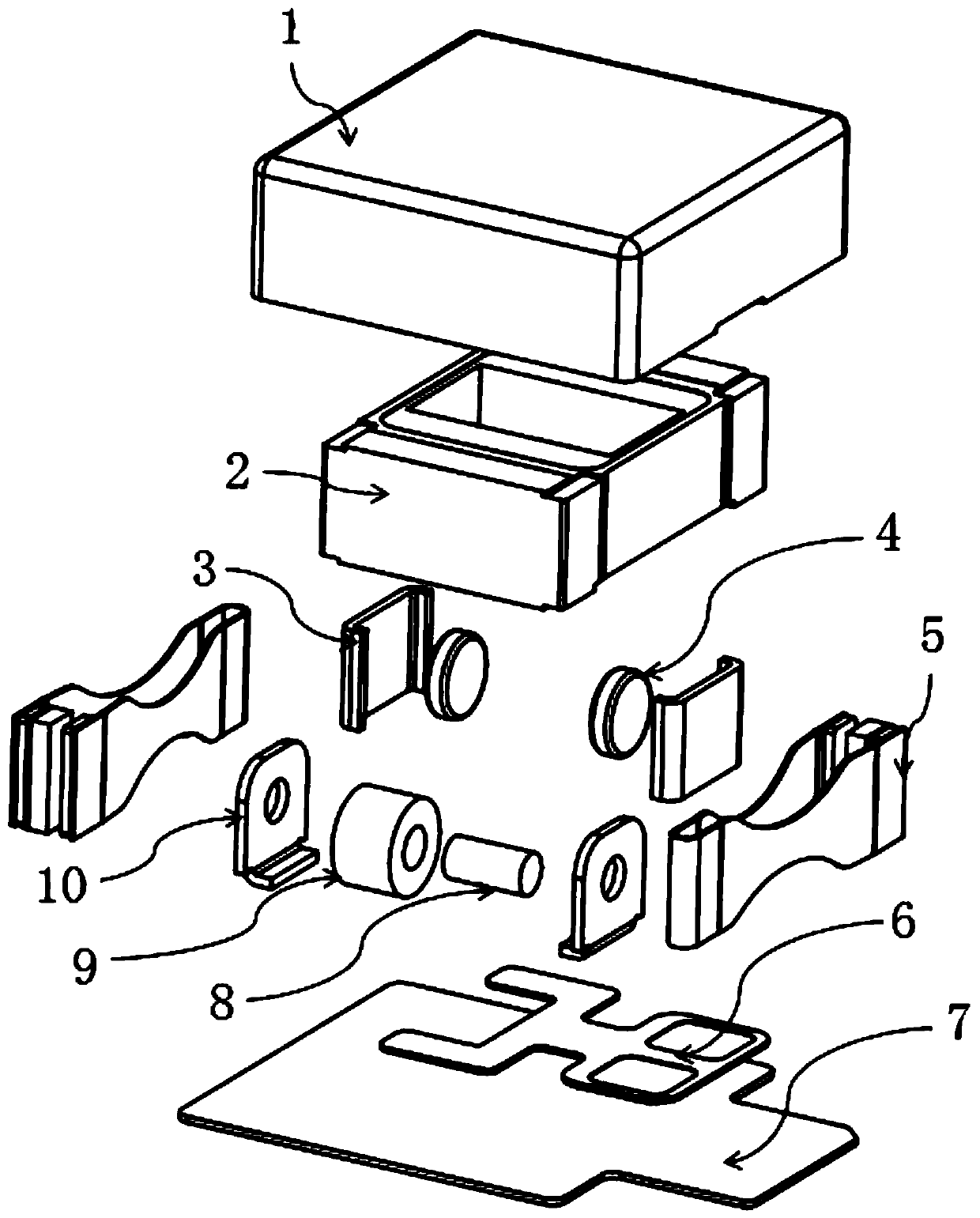

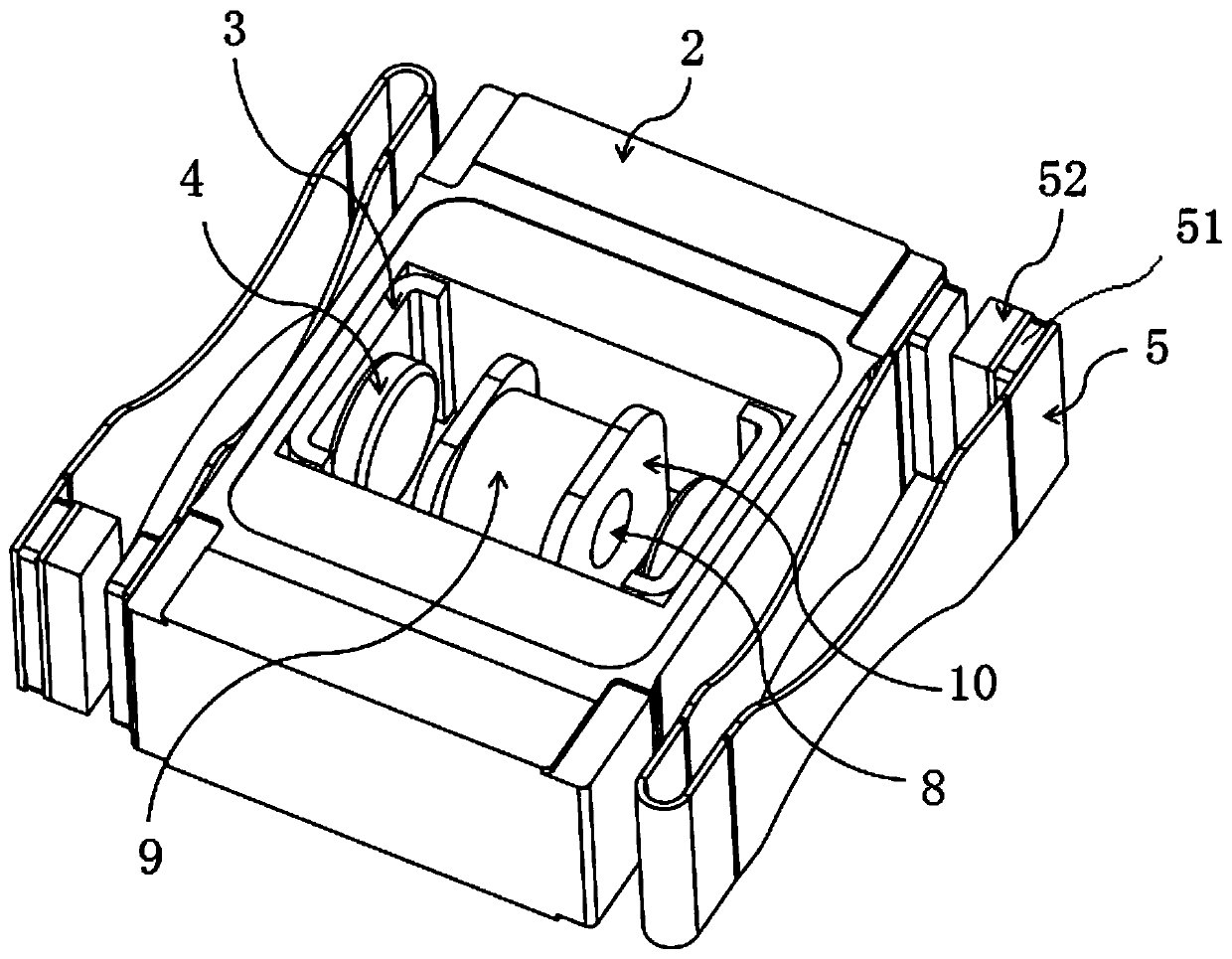

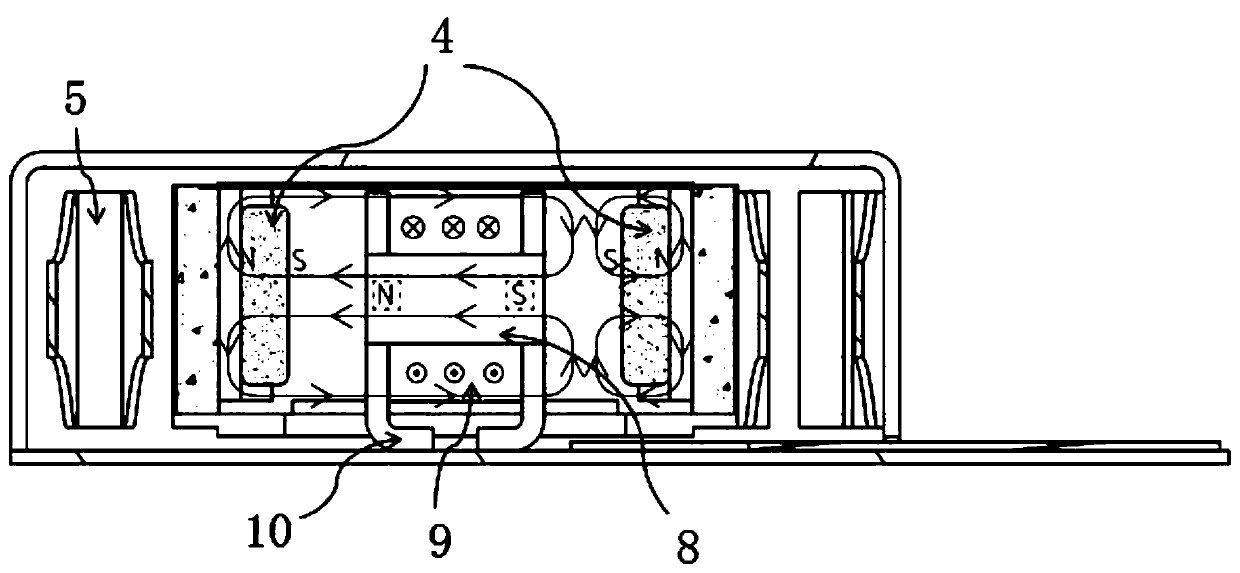

[0033] see Figure 1-3 , the present invention provides the following technical solutions: an electromagnet type horizontal linear vibration motor, including a casing 1, a support 7 is connected to the bottom of the casing 1, a stator assembly is connected to the top of the support 7, and the stator assembly includes a circuit board 6 and a coil 9, wherein the circuit board 6 is connected above the bracket 7, the circuit board 6 is a flexible circuit board, the circuit board 6 is provided with a coil 9, the coil 9 is electrically connected with the circuit board 6, and the inside of the casing 1 is provided with a vibrator assembly , the vibrator assembly includes a mass block 2, a cavity is provided inside the mass block 2, a magnet 4 is connected to both ends of the cavity, the magnet 4 is a cylindrical structure, the coil 9 is located between the two magnets 4, and the mass The block 2 is connected with the casing 1 through the spring leaf 5 .

[0034] Further, the magneti...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 lies in that further, the opposite sides of the connecting arms of the spring piece 5 are respectively connected to gaskets 51 , and a damping foam 52 is connected to one gasket 51 .

[0042] By adopting the above technical solution, the spacer 51 can evenly distribute the stress of the spring sheet 5 when it moves, and at the same time provide a bonding position for the damping foam 52. When the spring sheet 5 is squeezed and closed by the vibrator assembly, the damping foam 52 can be compressed smoothly, which is extremely Greatly shorten the free oscillation time of the spring leaf 5, speed up the motor response time, thereby shortening the stop time of the motor, the damping foam 52 is extremely slightly affected by temperature changes, and provides stable damping for the motor movement, without vibration enhancement at high temperatures. The vibration is weakened at low temperature, so it can well limit the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com