Acrylonitrile wastewater treatment method

A technology for acrylonitrile wastewater and treatment methods, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cleaning and maintenance costs and high risks, and improve COD and total nitrogen treatment effect, low operating cost and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

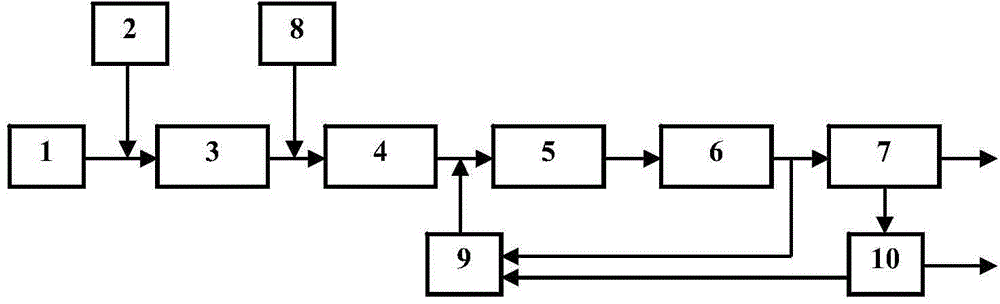

Image

Examples

Embodiment 1

[0041] The main water quality characteristics of the wastewater produced by an acrylonitrile factory are that COD is 4000mg / L, BOD / COD is 0.27, ammonia nitrogen is 55mg / L, total nitrogen is 687mg / L, and cyanide is 3mg / L. The main water quality characteristics of wastewater from a TMPD production plant are COD of 98000mg / L and BOD / COD of 0.72.

[0042] (1) homogeneous:

[0043] The acrylonitrile wastewater and TMPD wastewater are mixed at a volume ratio of 18:1 and then enter the homogenization tank. A perforated pipe is installed at the bottom of the homogeneous tank. Compressed air is introduced into the perforated pipe, and the balanced adjustment of water quality is achieved through aeration and stirring. Water quality after adjustment: COD is 8810mg / L, BOD is 5850mg / L, total nitrogen is 650mg / L, and BOD / total nitrogen is 9.0.

[0044] Phosphorus salt is added to the effluent of the homogeneous pool to supplement the phosphorus element required by the biological metabolism...

Embodiment 2

[0057] The main water quality characteristics of the wastewater produced by an acrylonitrile factory are that COD is 2370mg / L, BOD / COD is 0.32, ammonia nitrogen is 42mg / L, total nitrogen is 420mg / L, and cyanide is 2.8mg / L. The main water quality characteristics of wastewater from a TMPD production plant are COD of 72000mg / L and BOD / COD of 0.69.

[0058] (1) homogeneous:

[0059] Acrylonitrile wastewater and TMPD wastewater are mixed at a volume ratio of 25:1 and then enter the homogenization tank. A perforated pipe is installed at the bottom of the homogeneous tank. Compressed air is introduced into the perforated pipe, and the balanced adjustment of water quality is achieved through aeration and stirring. Water quality after adjustment: COD is 4972mg / L, BOD is 3187mg / L, total nitrogen is 418mg / L, BOD / total nitrogen is 7.6.

[0060] Phosphorus salt is added to the effluent of the homogeneous pool to supplement the phosphorus element required by the biological metabolism proce...

Embodiment 3

[0073] The main water quality characteristics of the wastewater produced by an acrylonitrile factory are that COD is 3120mg / L, BOD / COD is 0.42, ammonia nitrogen is 62mg / L, total nitrogen is 625mg / L, and cyanide is 3mg / L. The main water quality characteristics of wastewater from a TMPD production plant are COD of 72000mg / L and BOD / COD of 0.69.

[0074] (1) homogeneous:

[0075] Acrylonitrile wastewater and TMPD wastewater are mixed at a volume ratio of 33:1 and then enter the homogenization tank. A perforated pipe is installed at the bottom of the homogeneous tank, and compressed air is introduced into the perforated pipe to achieve balanced adjustment of water quality through aeration and stirring. Water quality after adjustment: COD is 5150mg / L, BOD is 2950mg / L, total nitrogen is 590mg / L, and BOD / total nitrogen is 5.0.

[0076] Phosphorus salt is added to the effluent of the homogeneous pool to supplement the phosphorus element required by the biological metabolism process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com