Measuring device for gap of guide blade edge plates

A technology of guide vanes and measuring devices, applied in the field of aero-engines, can solve the problems of low efficiency, restricted production, large measurement errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

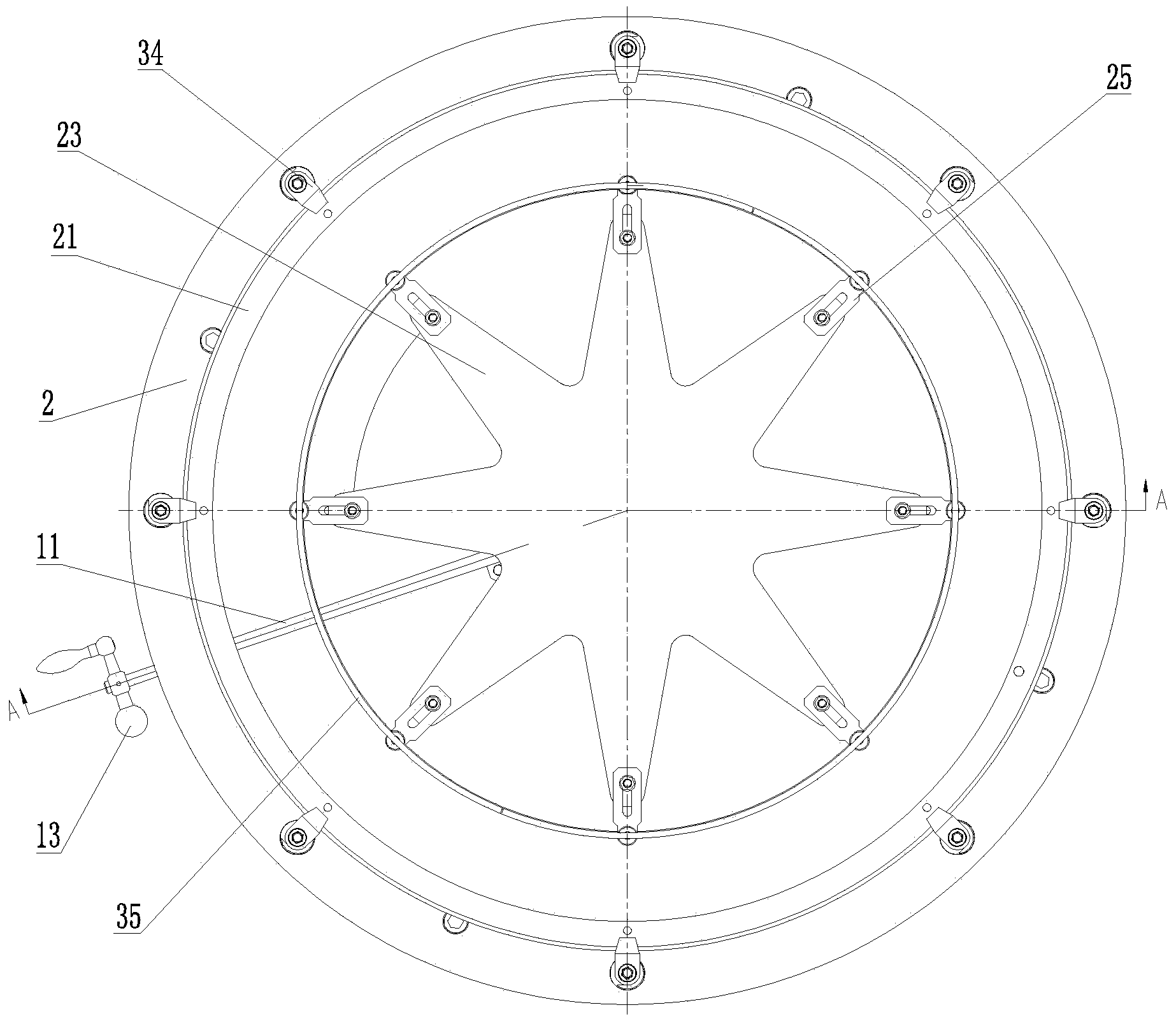

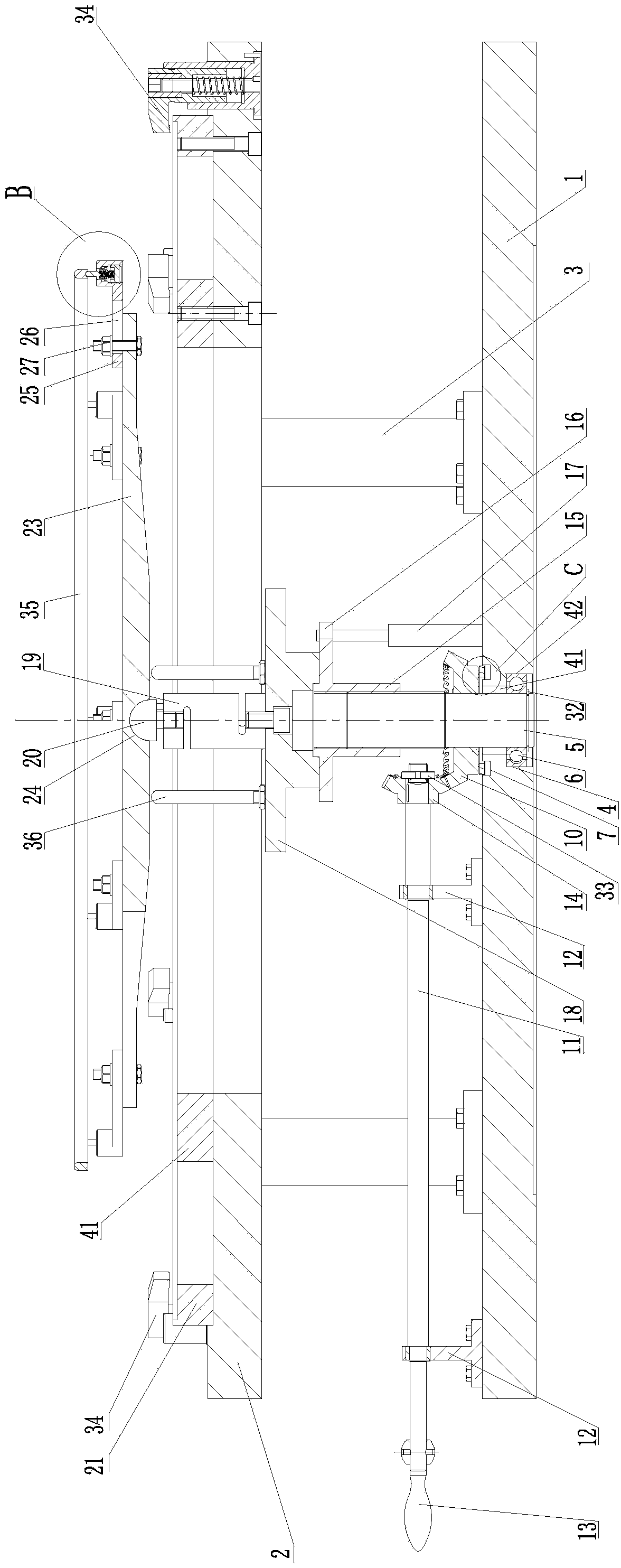

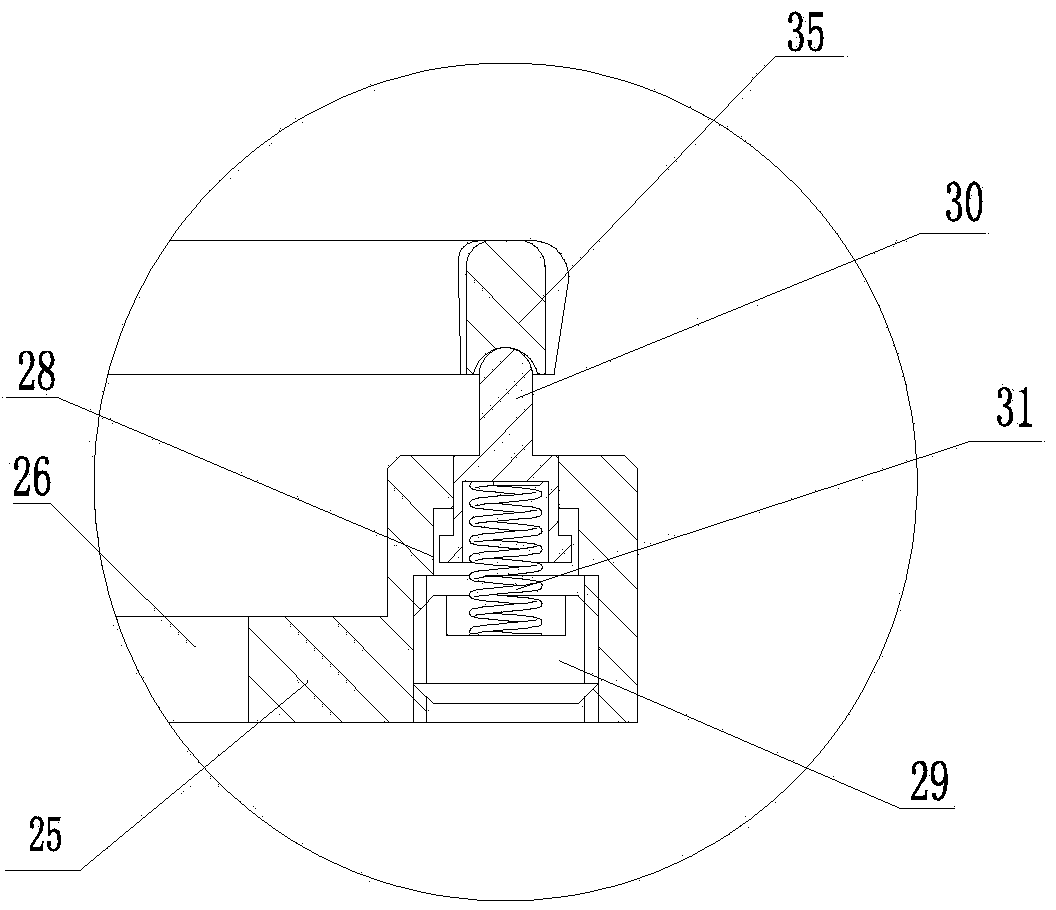

[0025] Such as Figure 1 to Figure 6As shown, a measuring device for guide vane edge plate clearance includes a chassis 1 on which a transmission mechanism, a force applying mechanism and a positioning mechanism are arranged; the transmission mechanism consists of a threaded rod 5, a screw sleeve 15, a guide pin 17, a measuring The dynamometer seat 18, the sensor 19 of the dynamometer, the pressure column 20, the angle frame 23, the guide plate 25, the thimble 30 and the support washer 35 are composed, and a through hole is arranged in the center of the chassis 1, and a threaded rod is arranged in the through hole 5, the bottom of the threaded rod 5 is connected with the chassis 1 through the bearing 6 arranged in the through hole of the chassis 1, the fit tolerance between the outer ring of the bearing 6 and the inner wall of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com