Frame structure beam plate column node oblique loading device

A technology of frame structure and loading device, which is used in the testing of measuring devices, machine/structural components, and the use of repetitive force/pulse force to test the strength of materials, etc. Stable pressure and reduced offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

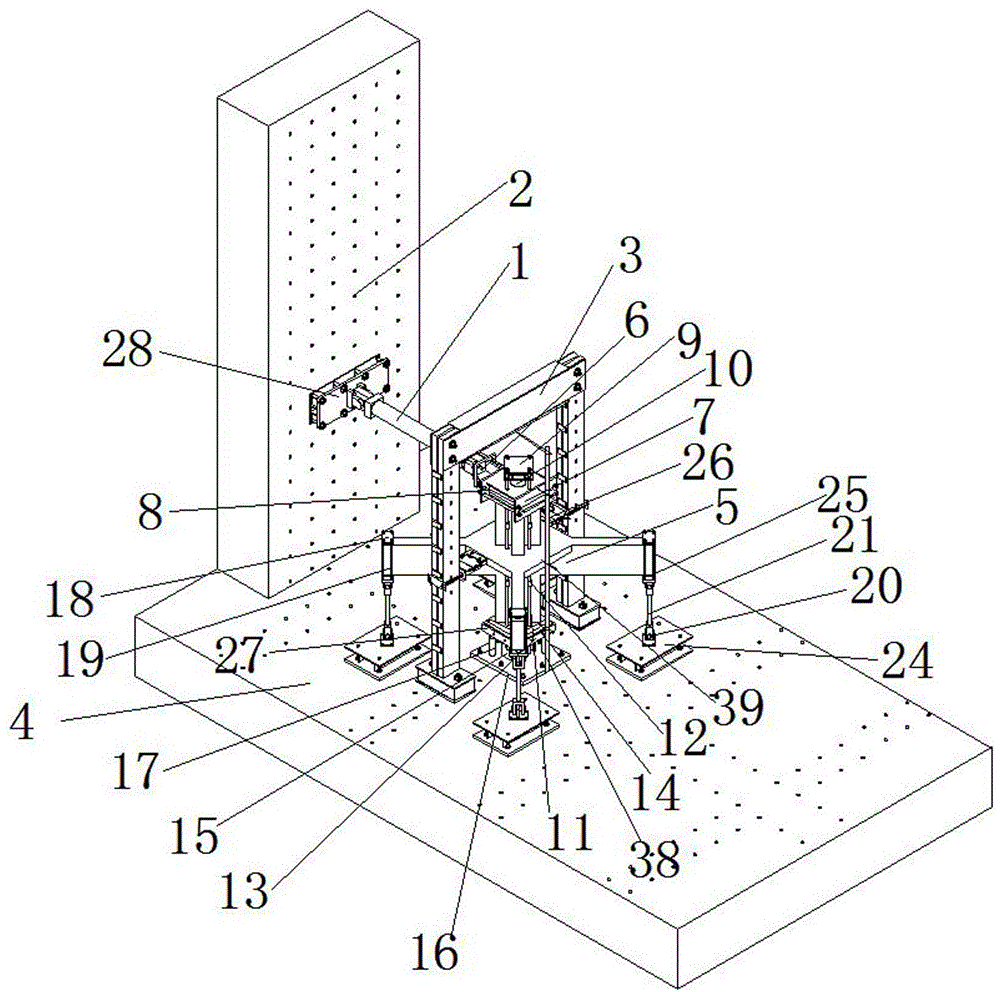

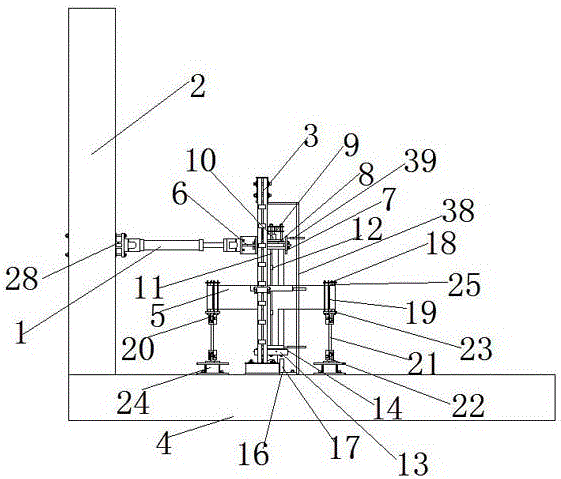

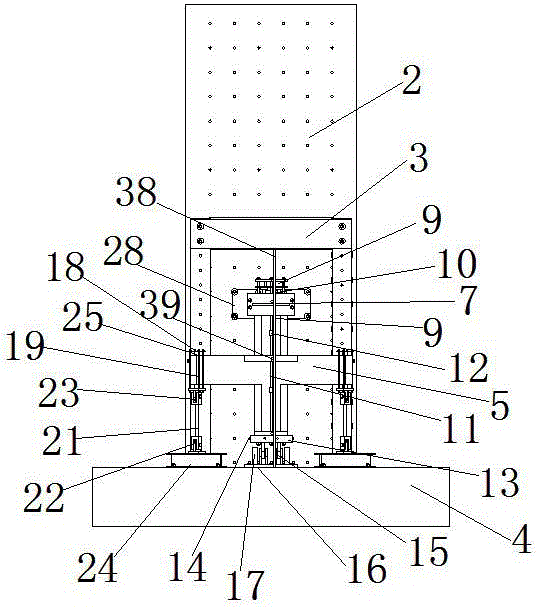

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , an oblique loading device for beam-slab-column joints of a frame structure, comprising a concrete reaction wall 2, a test bench 4, a door frame 3, a horizontal loading mechanism, an axial loading mechanism, a lateral limit mechanism, a beam end force measuring mechanism 26 and a horizontal Displacement Measuring Mechanism.

[0034] The horizontal loading mechanism includes MTS actuator 1, loading head 6, connecting rod 8 and connecting plate 7. The model of MTS actuator 1 is 201.70, the maximum thrust is 1000kN, the maximum pulling force is 950kN, and the stroke is 500mm. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com