Full-automatic glass cup welder

A glass cup, fully automatic technology, applied in glass production, glass molding, glass reshaping, etc., can solve the problems of long sealing time and low sealing efficiency of glass cups, achieve good welding effect, improve processing efficiency, and weld high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

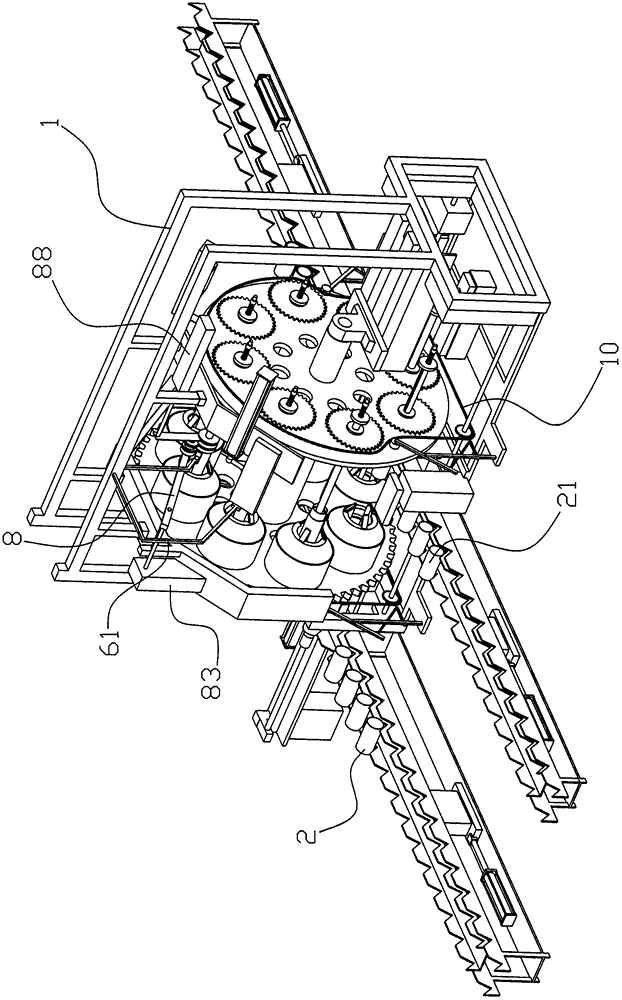

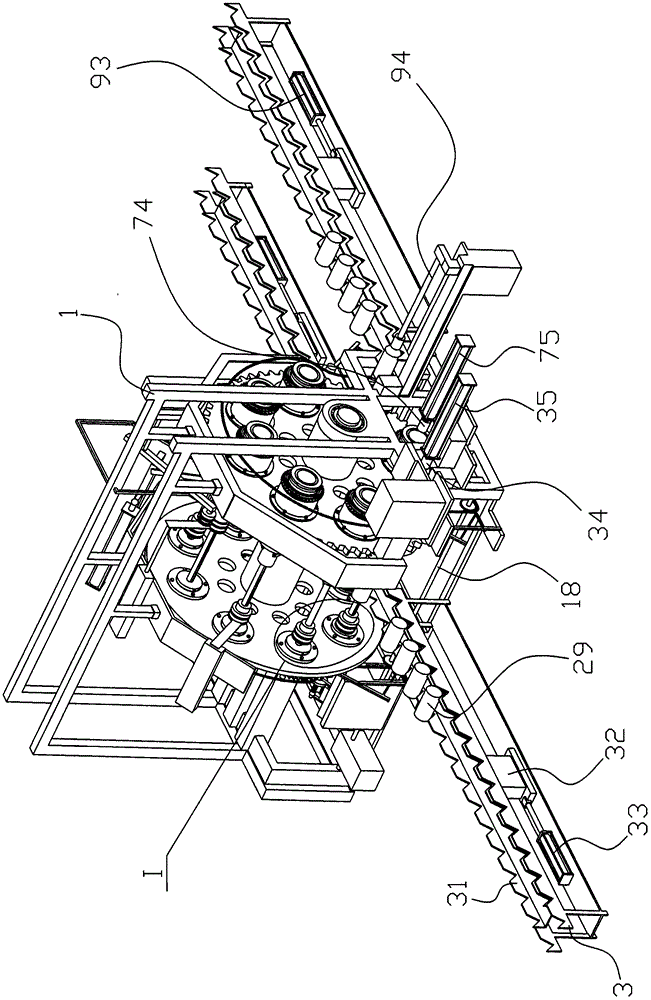

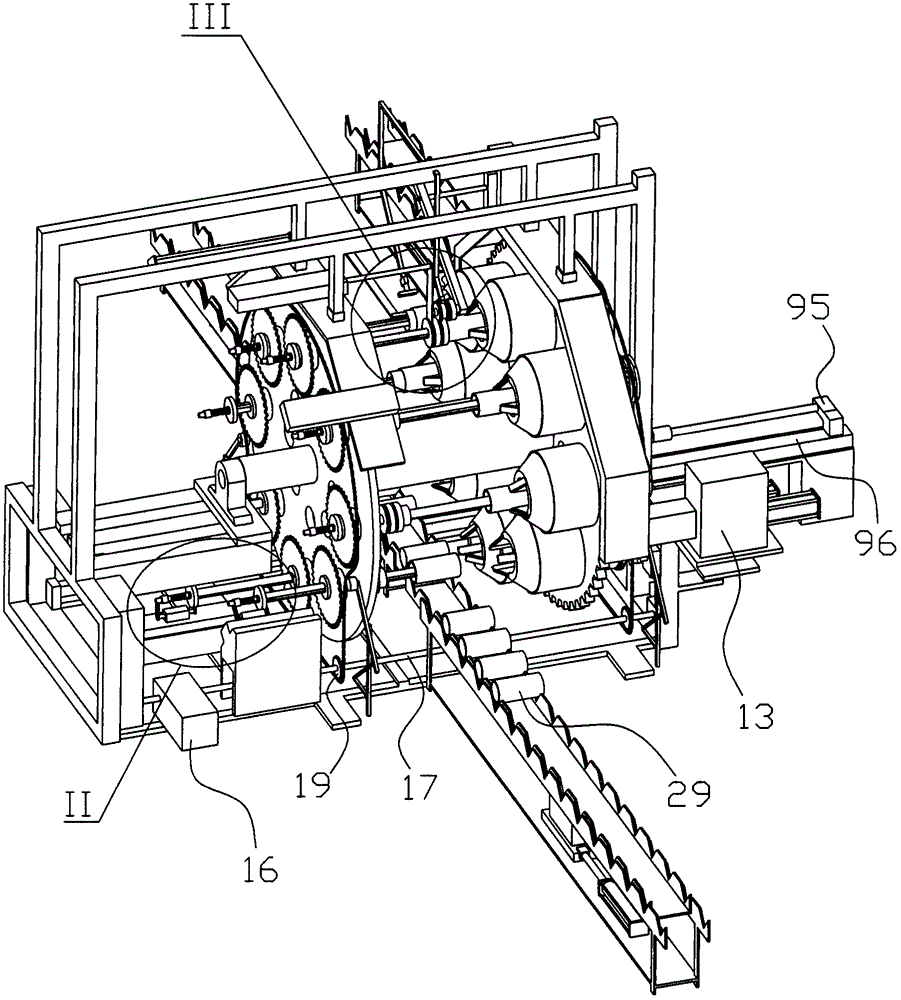

[0036] Such as Figure 1 to Figure 20 As shown, the fully automatic glass welding machine of the present embodiment includes a frame 1, which can clamp the outer clamping arm of the large glass 2, and can clamp the internal clamping arm of the small glass 21, and can push the internal clamping arm to The moving part in the outer card arm is a welding part that can weld the small glass 21 and the large glass 2 together. The first rotating disk 11 and the second rotating disk 11 that can rotate relative to the frame 1 are concentrically arranged on the frame 1. Rotating disk 12, the outer locking arms have N pieces, and the N outer locking arms are respectively rotatably arranged on the first rotating disk 11, and the inner locking arms are rotatably arranged on corresponding positions of the second rotating disk 12 , the first rotating disk 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com