Online type automatic drilling machine

A drilling machine and automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, driving devices, etc., can solve the problems of complex processing technology, difficult automatic production, low processing accuracy, etc., to achieve convenient use, The effect of smooth use and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

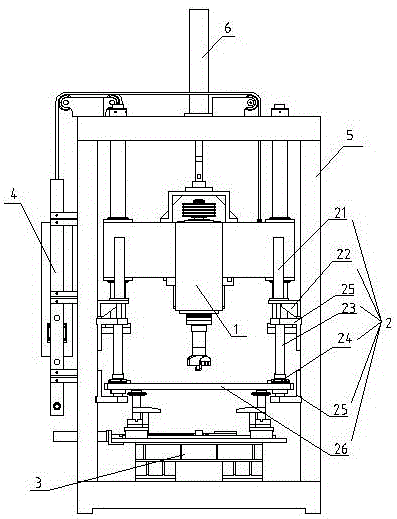

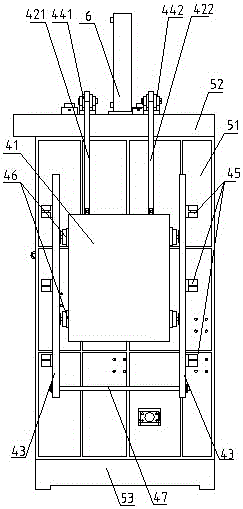

[0031] An online automatic drilling machine, which includes a frame 5, the frame 5 is a square structure, including a side plate 51, a top plate 52 and a bottom plate 53, a power head mechanism 1 is provided inside the frame, and a pressing plate Mechanism 2, positioning claw mechanism 3 and power head automatic return mechanism 4;

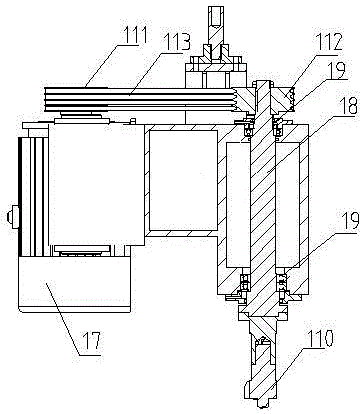

[0032] The power head mechanism 1 includes a power head box body 11, four guide posts 12 are arranged on the four sides of the power head box body, the top of the guide post 12 is connected and fixed on the top plate of the frame, and the bottom is connected and fixed on the side of the frame On the inside of the board, the power head box 11 is fixedly connected to the frame through the guide post 12, and the top of the power head box 11 is provided with an oil cylinder connecting device 13, and the oil cylinder connecting device 13 sequentially includes an oil cylinder connecting frame from bottom to top 131, the oil cylinder connecting plate 132...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com