Efficient feeding mechanism and method for DC plug production line

A production line, high-efficiency technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of insufficient material efficiency on the production line, and achieve the effect of maintenance, difficult maintenance, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

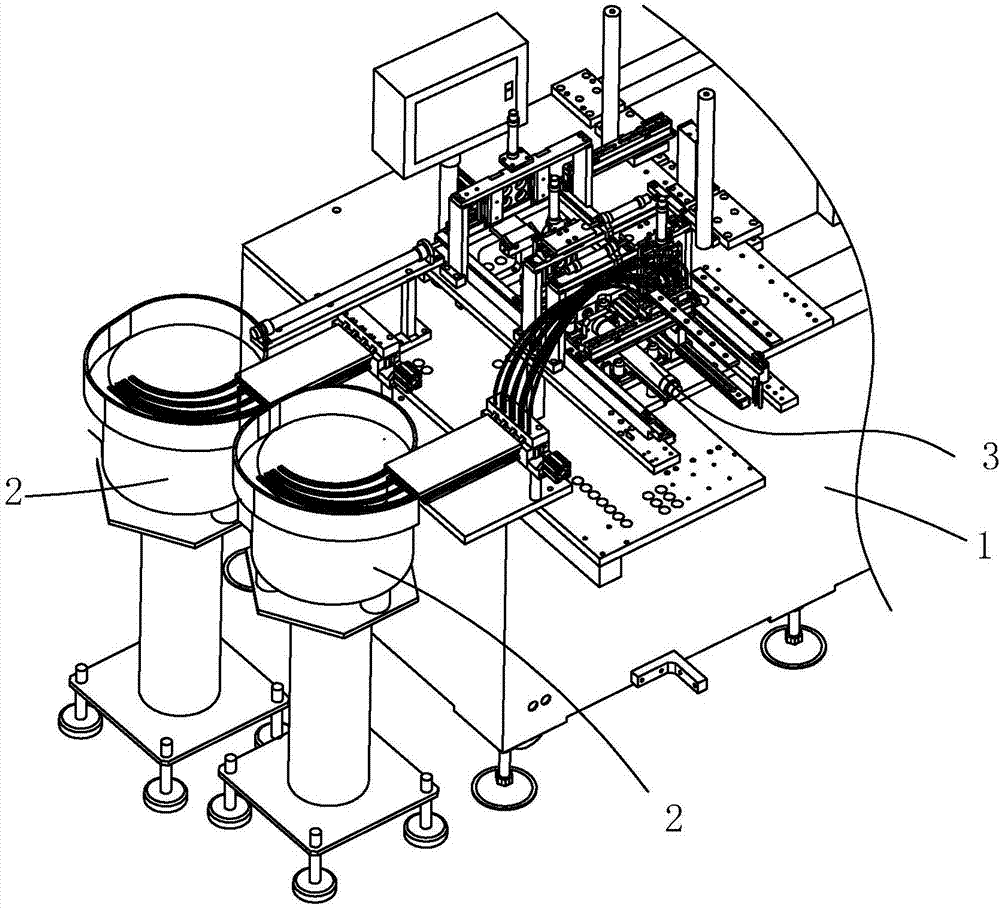

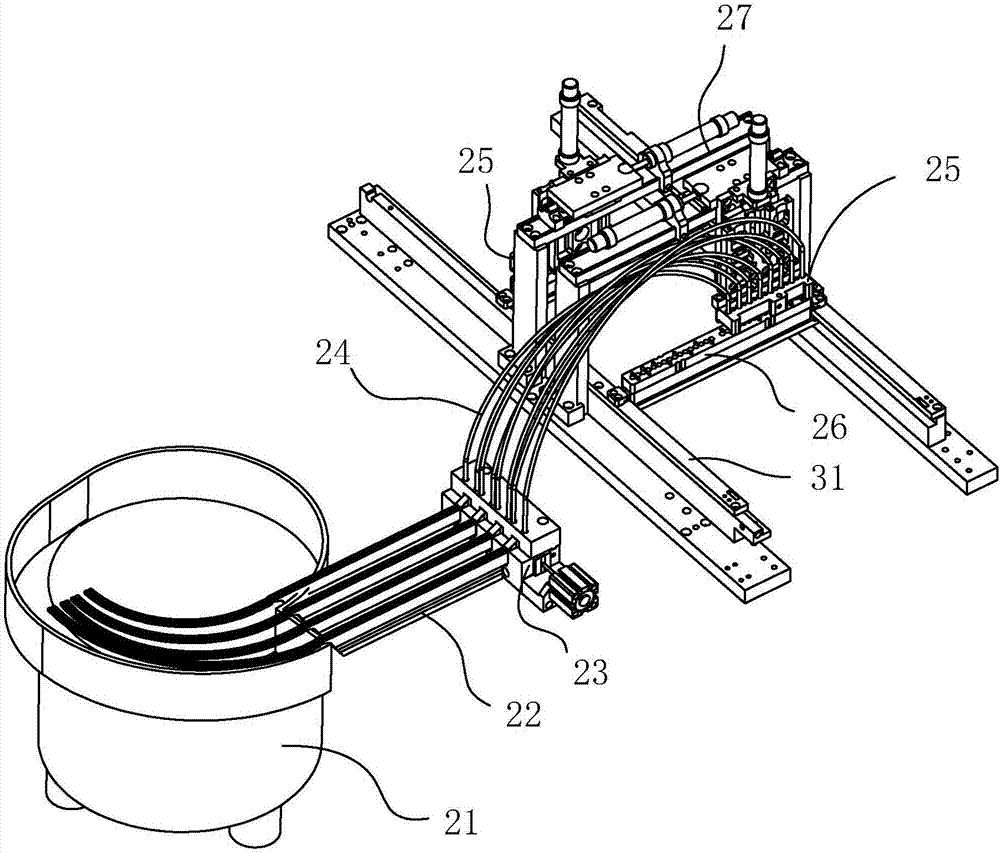

[0055] Example 1: An efficient feeding mechanism for DC plug production line, such as figure 1 with 2 As shown, it includes a frame 1, a mold strip 26 for centrally feeding the production line, a conveying assembly 3 for conveying the mold strip 26, and two loading assemblies 2 located upstream and downstream. The die bar 26 is provided with material receiving holes 261 evenly arranged perpendicular to the conveying direction. The material receiving holes 261 are used to load the parts of the DC plug. Picture 10 .

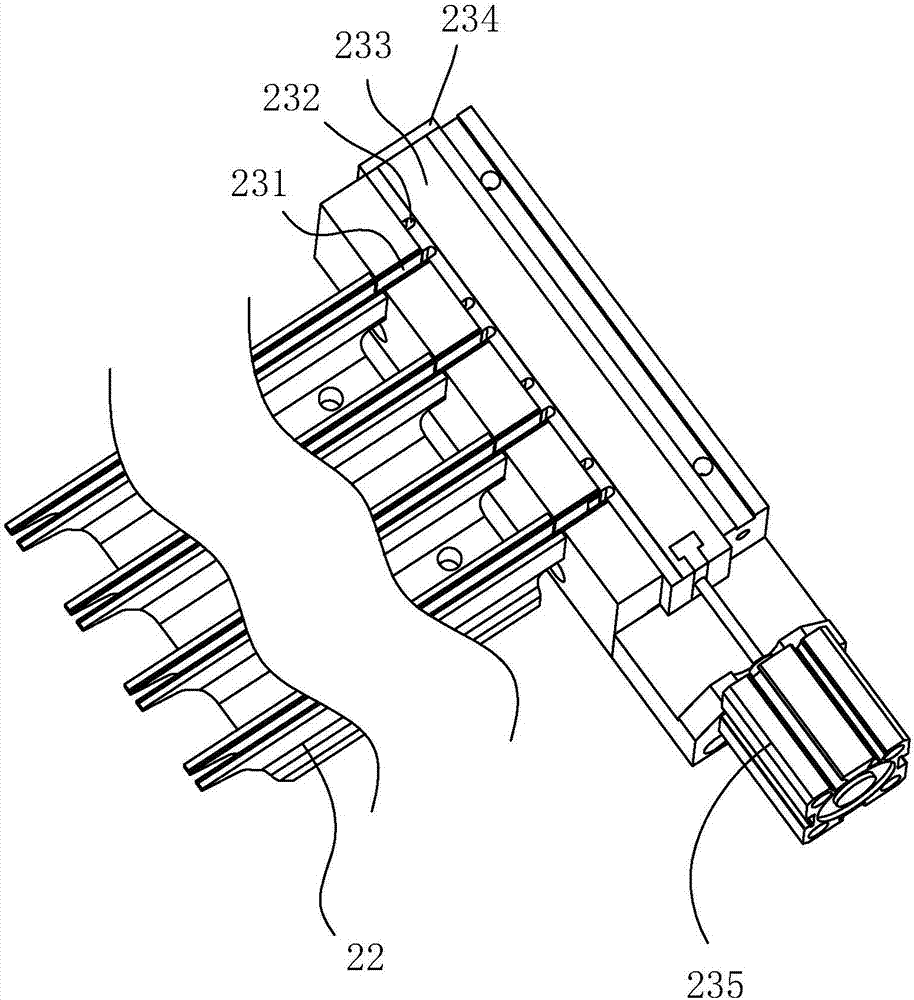

[0056] Reference figure 2 , The two feeding assemblies 2 each include a vibrating plate 21 interconnected from upstream to downstream, four conveying guide rails 22, a distribution rack 23, eight conveying pipes 24 for conveying parts by air pressure, and a guide plate 25; However, the guide plates 25 of the two feeding assemblies 2 are respectively located on the two sides of the mold strip 26 arranged along the holes. The vibrating disc 21 is mainly used for scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com