Contact switching device

A technology of switching devices and contacts, which is applied in the directions of detailed information of electromagnetic relays, relays, electrical components, etc., can solve the problems of deviation of action characteristics, high positioning accuracy, assembly errors, etc., and achieve low manufacturing costs, simple assembly operations, and difficult The effect of assembly error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

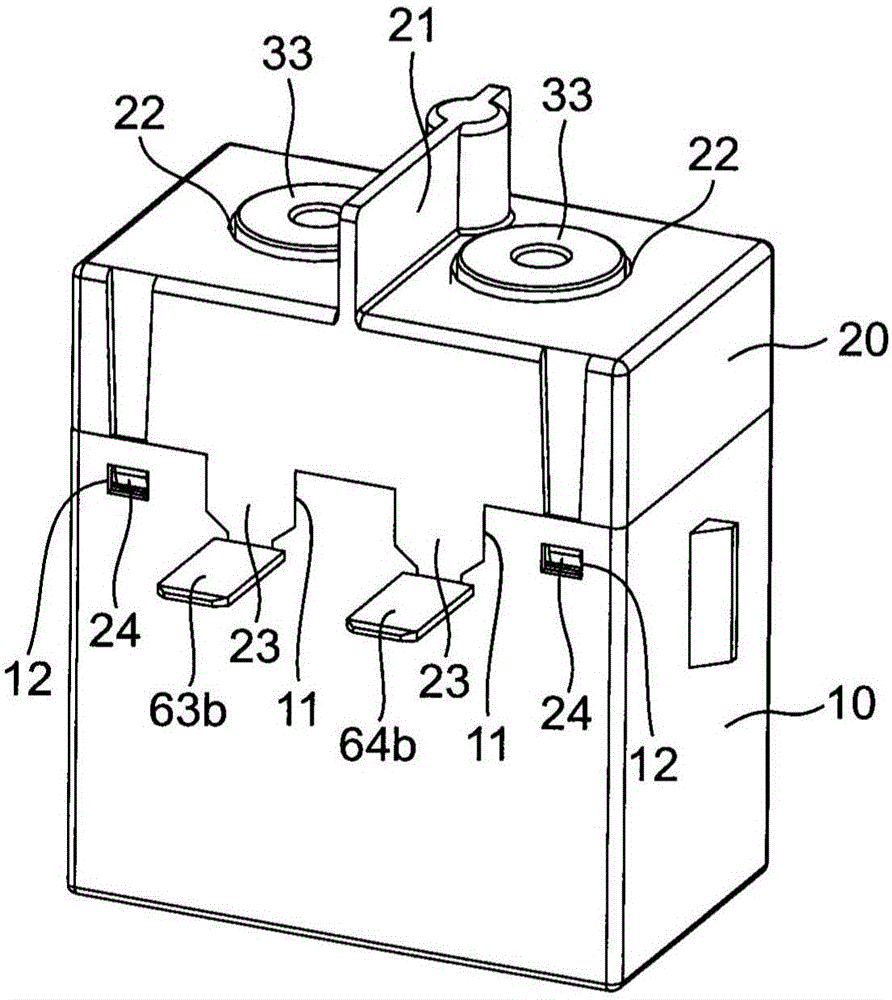

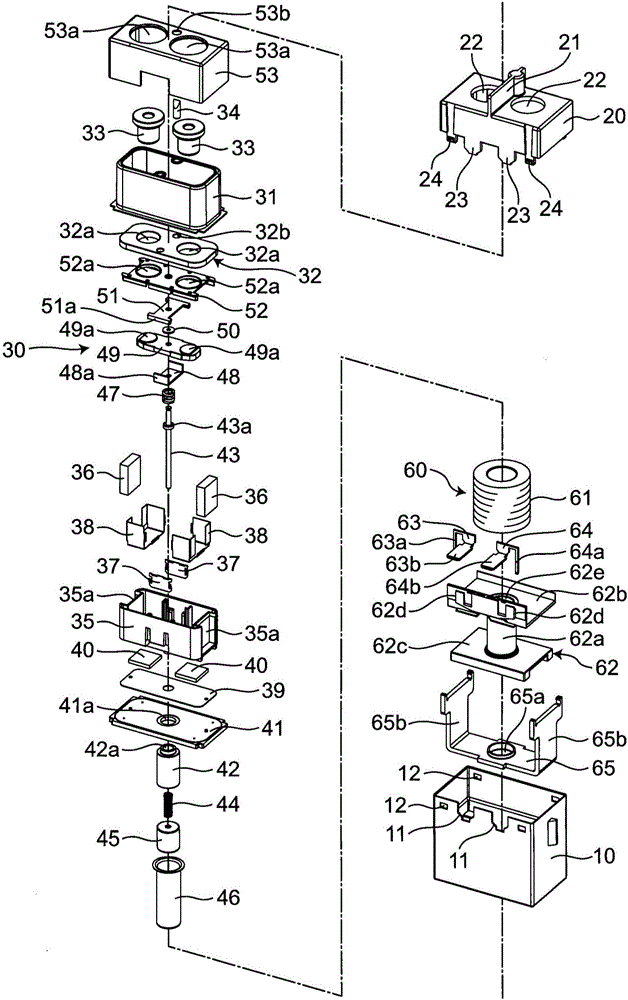

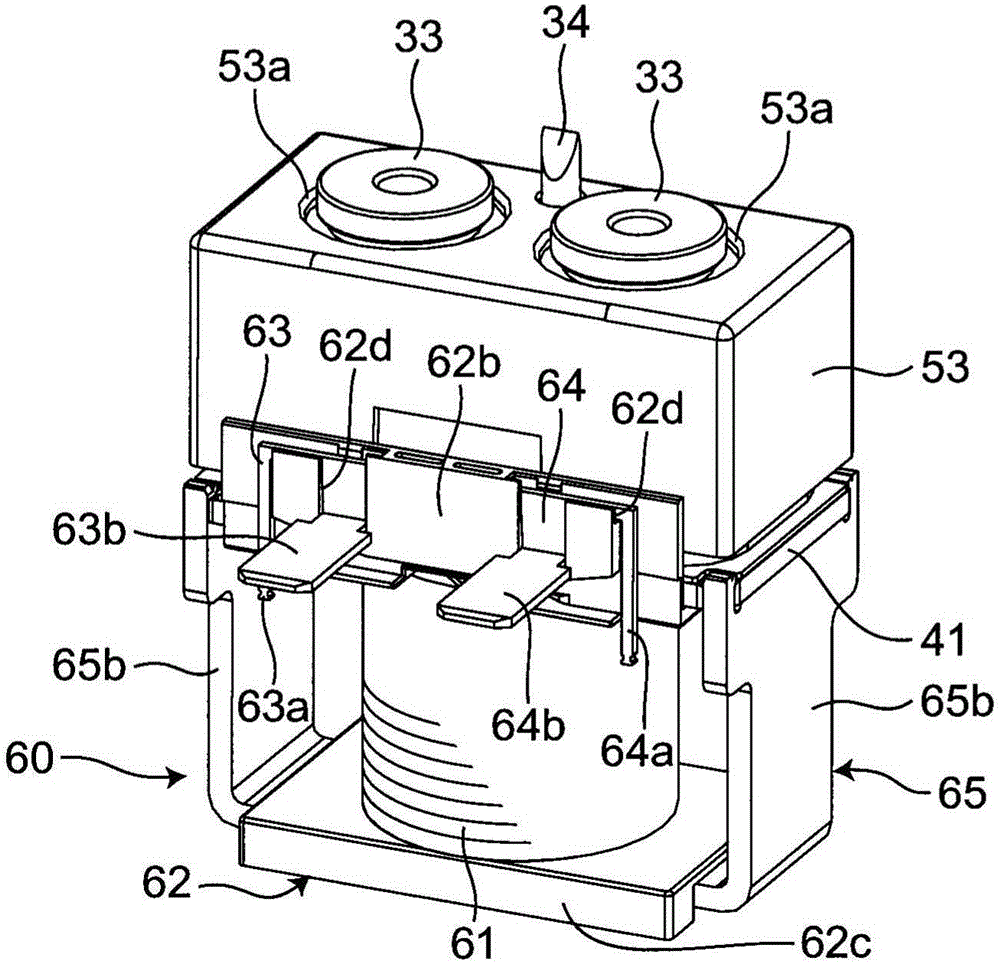

[0043] according to Figure 1 to Figure 17 The accompanying drawings describe the case where the contact switching device according to the embodiment of the present invention is applied to a sealed electromagnetic relay.

[0044] The sealed electromagnetic relay of this embodiment includes at least an electromagnet unit 60 , a holder 35 , a movable shaft 43 , a movable contact piece 49 , a movable yoke 48 , a pair of fixed contacts 33 a and a fixed yoke 51 . Specifically, as Figure 1 to Figure 5 As shown, the case 10 is assembled with the cover 20 to form a case, and the contact mechanism unit 30 and the electromagnet unit 60 are incorporated in the case.

[0045] Such as figure 2 As shown, the housing 10 is an insulating resin molding in a substantially rectangular box shape, and a set of notches 11 are formed on one side of the opening edge. In addition, the housing 10 is provided with a total of two pairs of locking holes 12 at both ends of the opening edge portions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com