Wiper blade

A technology of wiper and leaf spring, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of uneven wiping, small and uneven pressure on the windshield surface of the wiper swing arm, and achieve Improve the following performance, improve the excellent appearance, and improve the effect of the overall feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

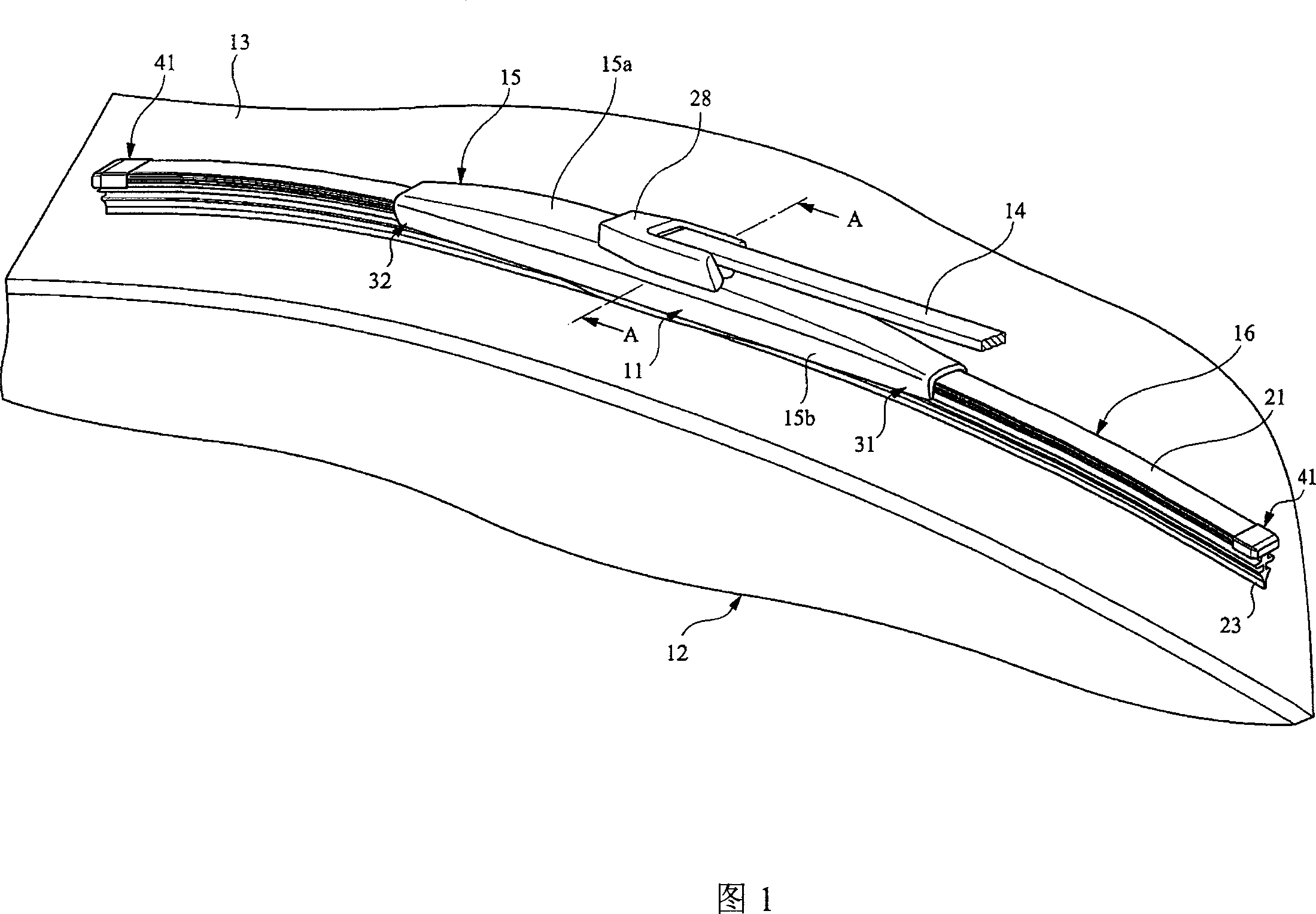

[0042] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0043] FIG. 1 is a perspective view showing a state of use of a wiper blade according to a preferred embodiment of the present invention. The wiper blade 11 shown in FIG. 1 is used to wipe off the attachments attached to the front windshield 13 (hereinafter referred to as the windshield 13 ) of the vehicle 12 , such as raindrops and water droplets falling on the forward moving vehicle.

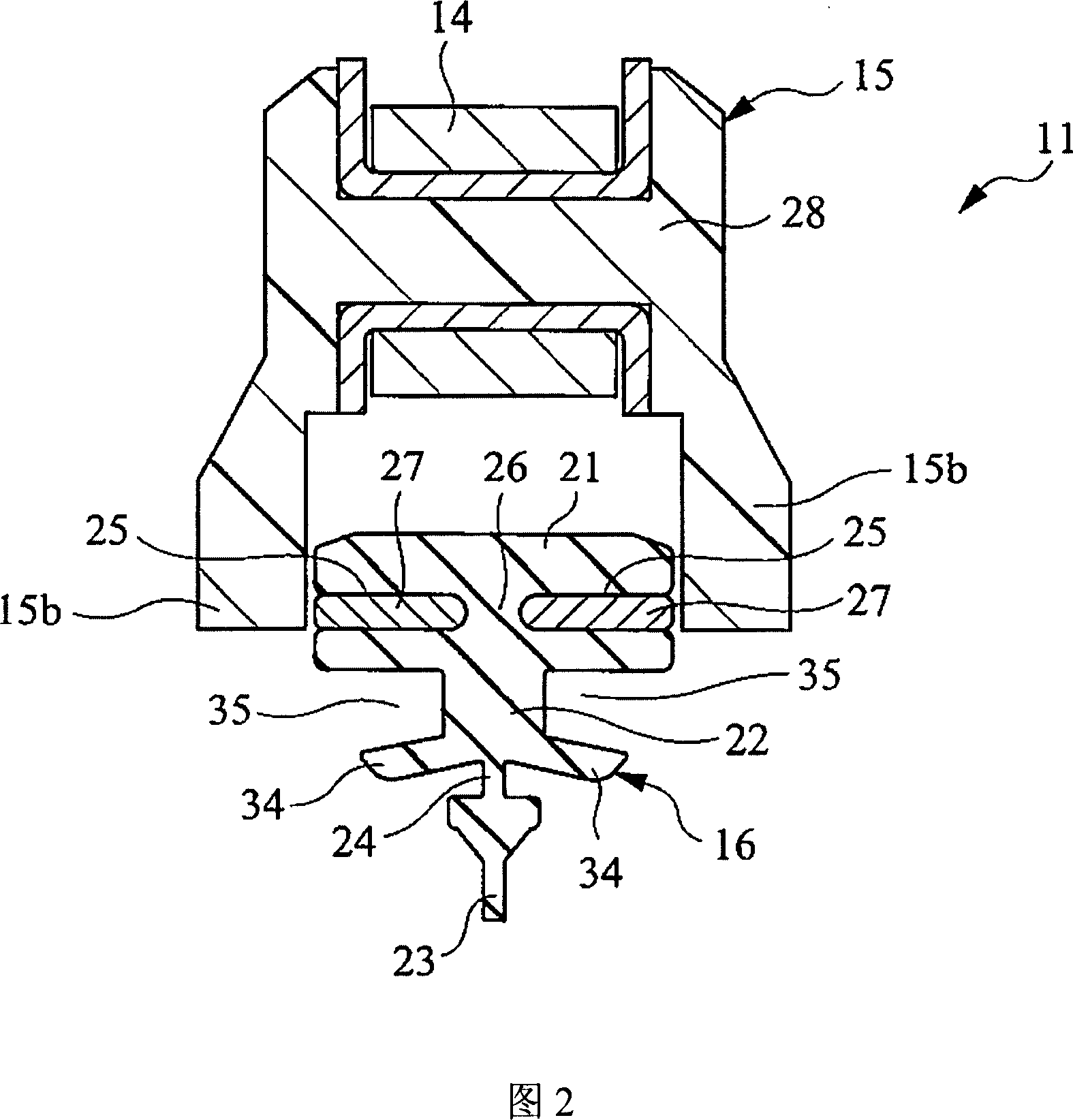

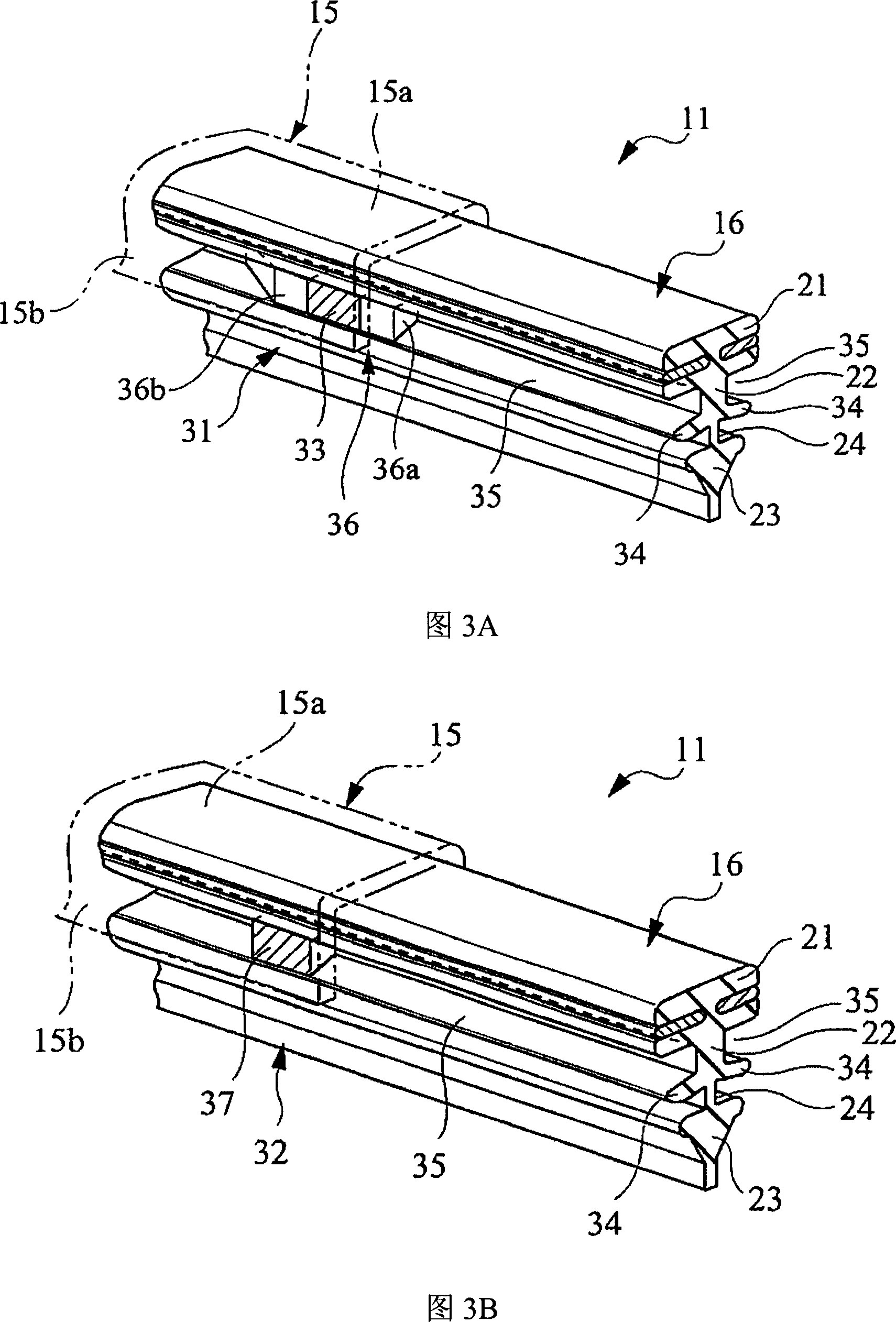

[0044] The wiper blade 11 has a rubber retainer 15 connected to the end of a wiper swing arm 14 that can swing on the vehicle 12; 15 holds a rubber sheet 16 , wherein the rubber sheet 16 comes into elastic contact with the windshield 13 by the pressure of the wiper swing arm 14 exerted by the rubber holder 15 . And, when a wiper motor, not shown, drives the wiper swing arm 14, the wiper blade 11 swings on the windshield 13 together with the wiper swing arm 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com