Gap part aligning and mistaken delivery detecting structure

A technology of misfeed detection and notch, applied in the field of notch parts guide and misfeed detection and guide structure, it can solve the problems of inapplicability, misfeed of guide pin positioning, unable to correct in time, etc., to achieve good positioning effect and not easy to deviate. , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described below in conjunction with the drawings.

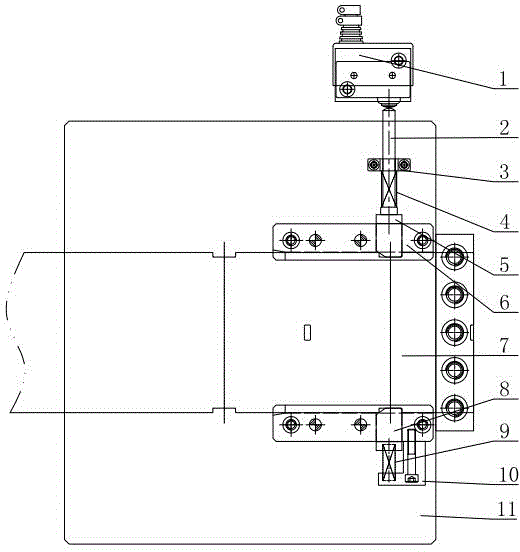

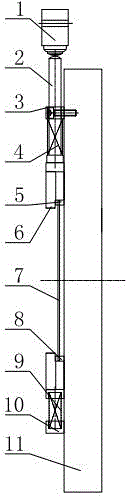

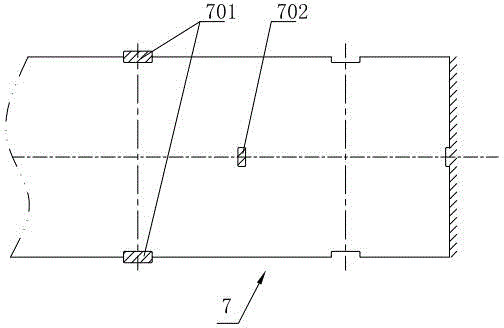

[0016] Such as figure 1 , figure 2 As shown, the notch component guide and misfeed detection structure of this embodiment includes a concave mold 11, a material belt 7 conveyed by a feeder is arranged in the middle of the concave mold 11, and evenly-spaced gaps 701 are opened on both sides of the material belt 7. On the mold 11, a symmetrically arranged strip guide plate 6 is fixed by fasteners. The guide plates 6 are respectively located on both sides of the strip 7; the first push block 5 is installed on the guide plate 6 at the upper end. An associated pin 2 is installed at the upper end of the push block 5, a first spring 4 is sleeved on the associated pin 2, and the associated pin 2 passes through the fixed block 3 installed on the die 11; the second push block 8 is installed on the guide plate 6 at the lower end , The guide plate 6 at the lower end is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com