Precision edge cutting device for thin film for capacitor

A capacitor and cutting device technology, applied in the field of capacitors, can solve problems such as inability to achieve precise positioning, inability to effectively fix, slow edge trimming, etc., and achieve the effect of preventing deviation, moving smoothly, and not easily causing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

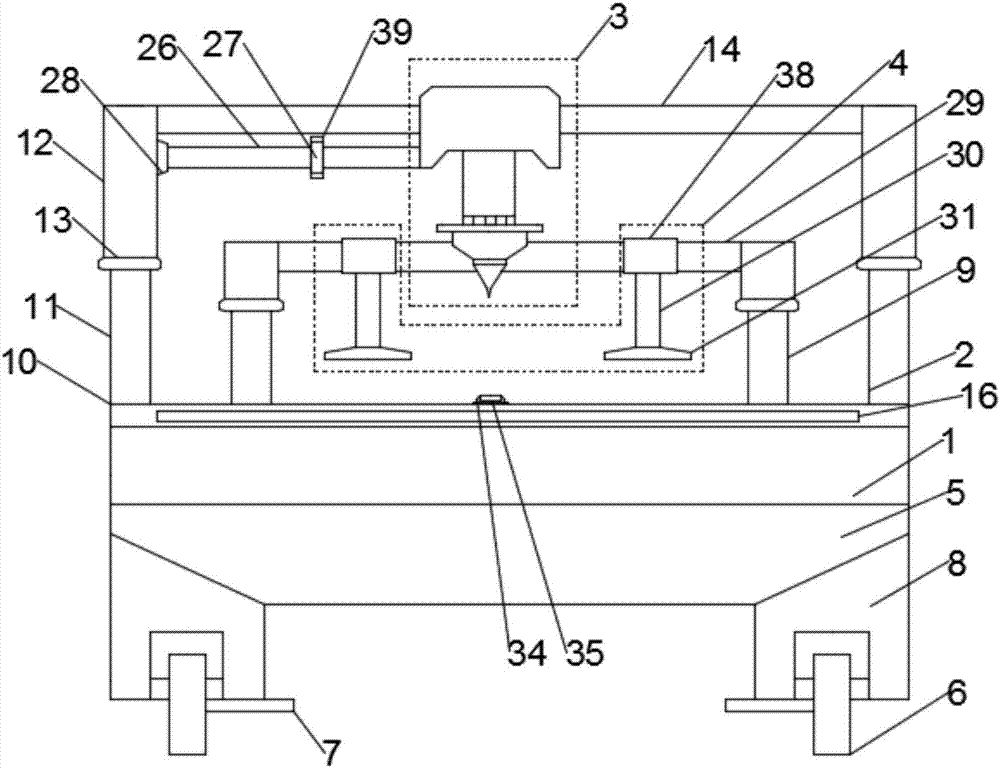

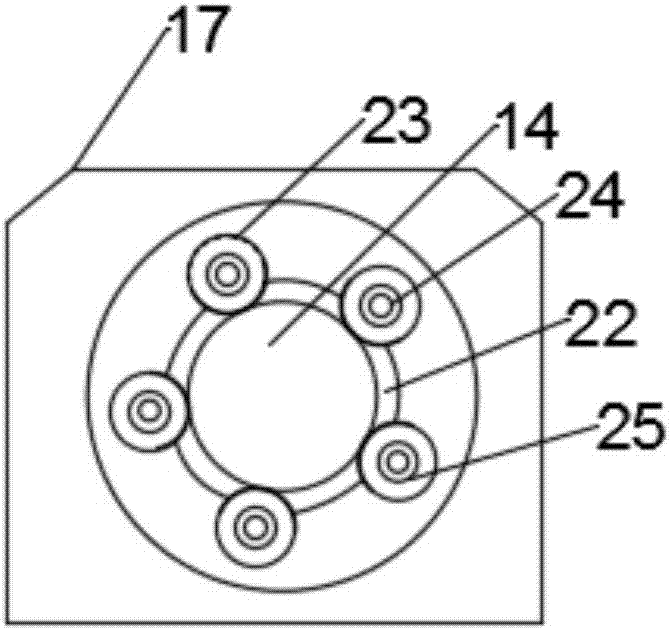

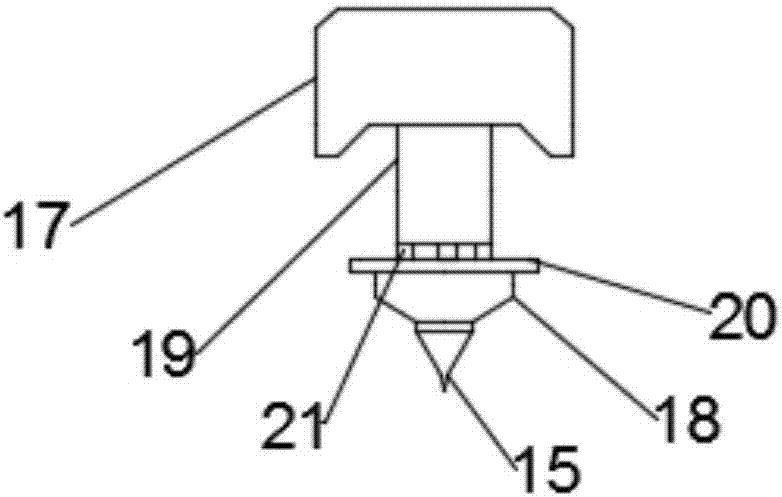

[0022] see Figure 1 to Figure 4 , the present invention provides a technical solution: a precision trimming device for capacitor films, including a workbench 1, a first support frame 2, a second support frame 9, a cutting device 3 and a positioning device 4, the support frame 2 The quantity is two, and the cutting device 3 and the positioning device 4 are installed on the upper surface of the workbench 1 through the first support frame 2 and the second support frame 9 respectively, and the first support frame 2 and the second support frame 9 are both Composed of two support rods 10, the cutting device 3 includes a sliding shaft 14, an edge trimming table 17 and a cutting knife 15, one end of the cutting knife 15 is fixed inside the fixed seat 18, and the bottom end of the edge trimming table 17 is connected with Hydraulic rod 19, the bottom end of the hydraulic rod 19 is connected together through the connecting plate 20 and the fixed seat 18, the inside of the trimming table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com