Cutter holder and main shaft device

A technology of spindle device and tool holder, which is applied in the direction of positioning device, drive device, clamping, etc., can solve the problems of tool installation angle deviation and eccentricity, tool holder installation angle deviation and eccentricity, and difficult tool holder installation and removal, etc., to ensure easy The effect of loading and unloading and not easy to deviate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, Embodiment 1 of the present invention will be described according to the accompanying drawings.

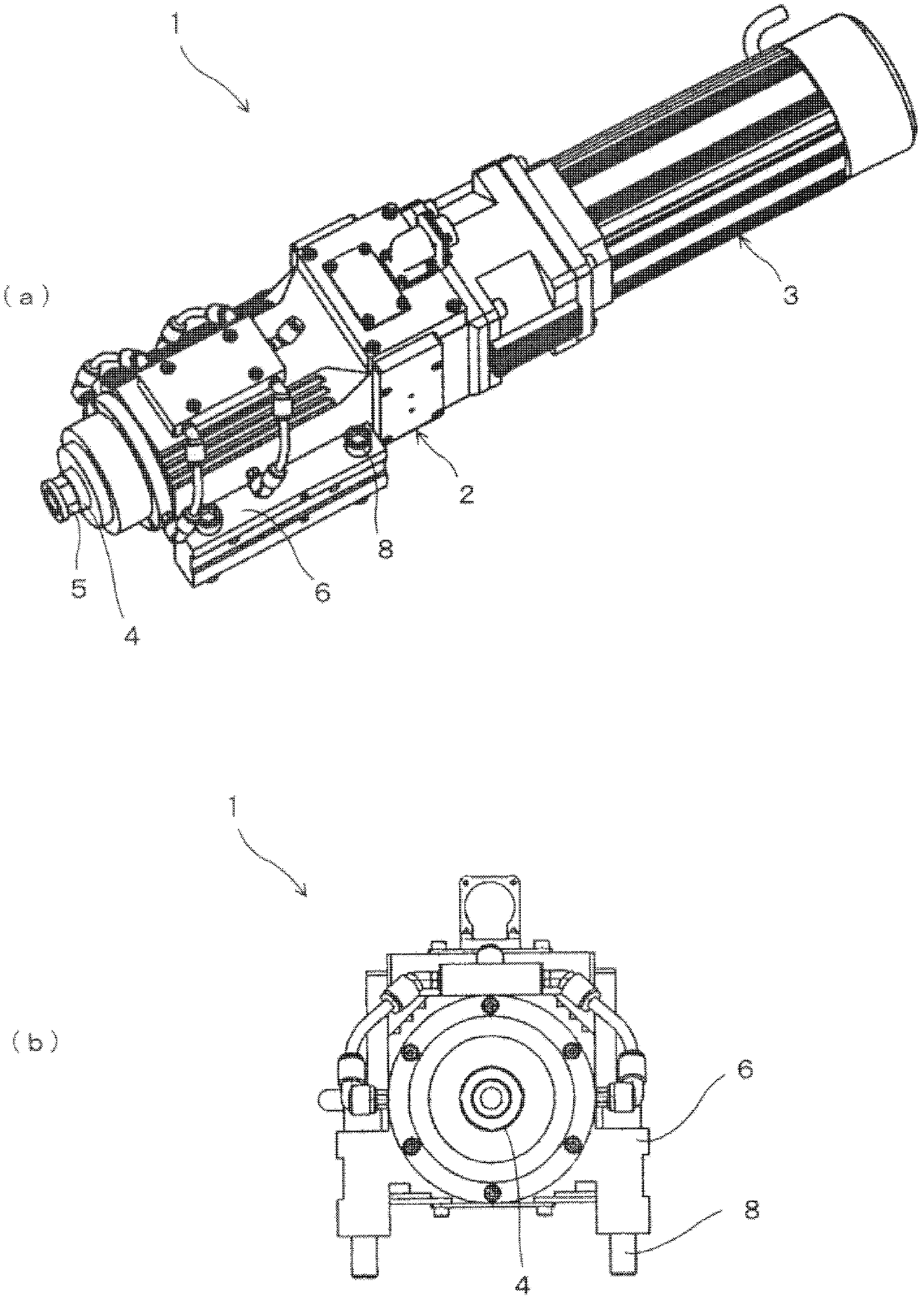

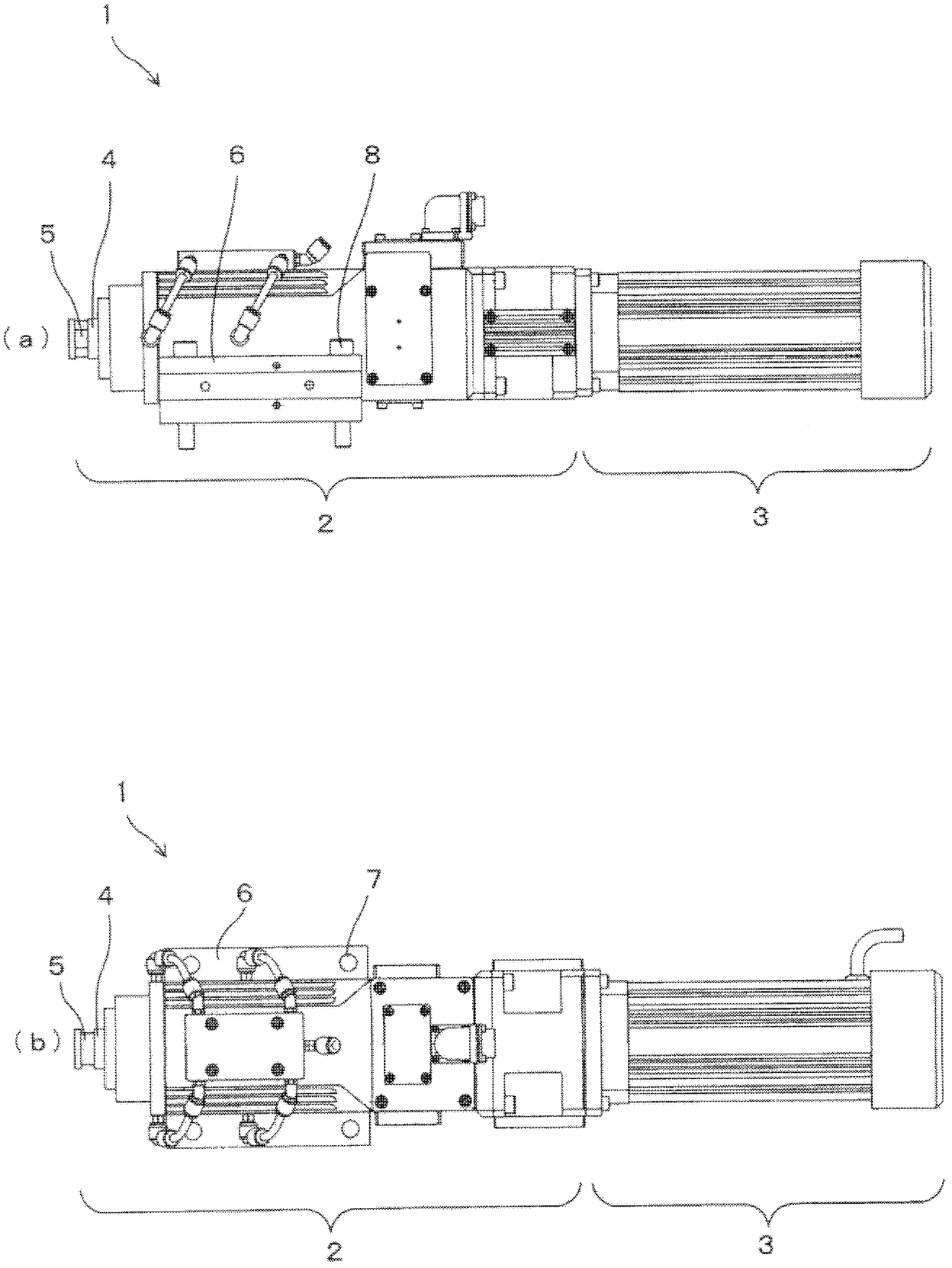

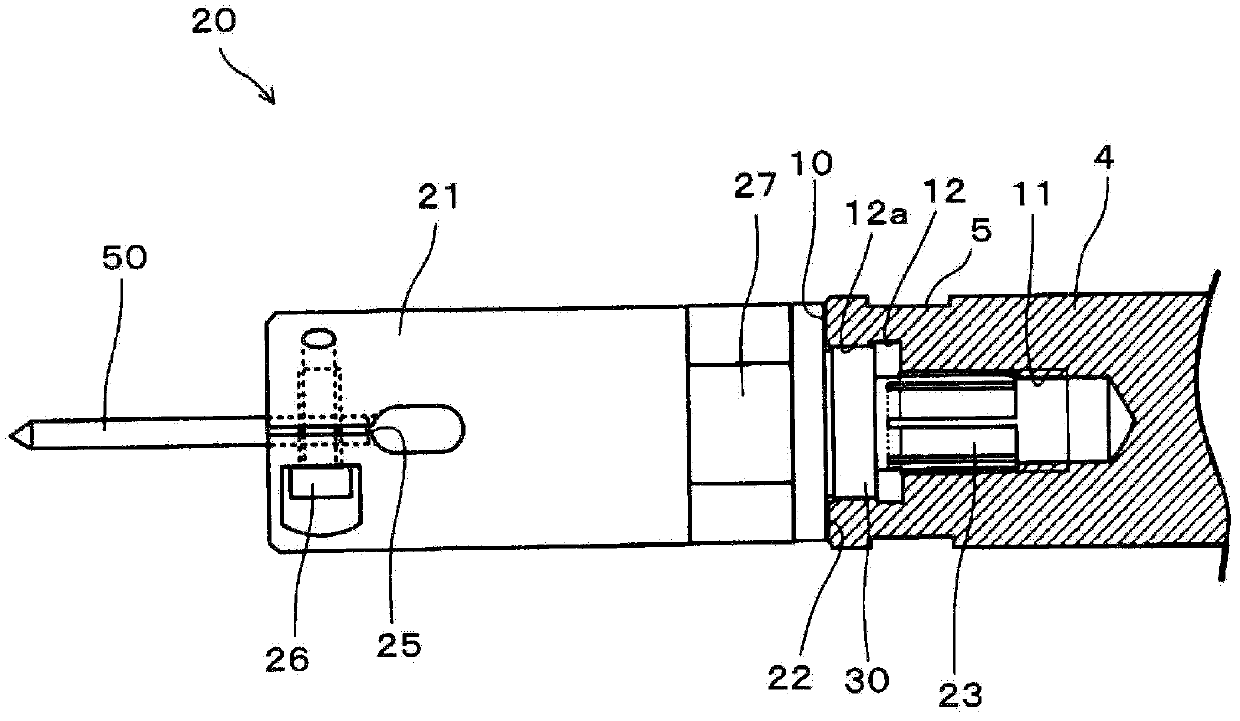

[0036] This embodiment is an example of applying the present invention to an ultrasonic spindle device. The ultrasonic spindle device 1 of the present embodiment is as Figure 1 ~ Figure 2 , is composed of ultrasonic main shaft body 2 and motor 3 . The ultrasonic spindle main body 2 has a rotating shaft 4 (spindle) driven and rotated by a motor 3, and a bearing mechanism for holding the rotating shaft 4 rotatably and vibratingly. Ultrasonic vibration excitation unit (for example, composed of piezoelectric elements), cooling mechanism, etc. In addition, the ultrasonic vibration applied to the rotating shaft 4 is a vibration having a frequency equivalent to that of the ultrasonic wave, usually an axial vibration, and its amplitude is, for example, only several μm.

[0037] Such as figure 1 As shown in (a) etc., the distal end portion of the rotating shaft 4 is expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com