Cylindrical horizontal physical simulation test device for coal mine sinking and driving engineering

A technology of engineering physics and simulation tests, applied to teaching models, using stable tension/pressure to test the strength of materials, instruments, etc., can solve difficult three-dimensional simulation tests or simulation tests, and it is difficult to ensure that the boundary conditions of the model meet the boundary conditions, Problems such as not developing a large-scale test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

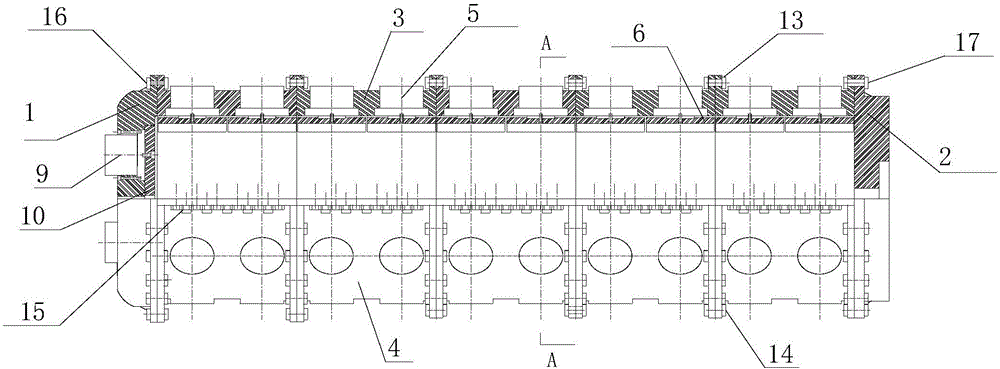

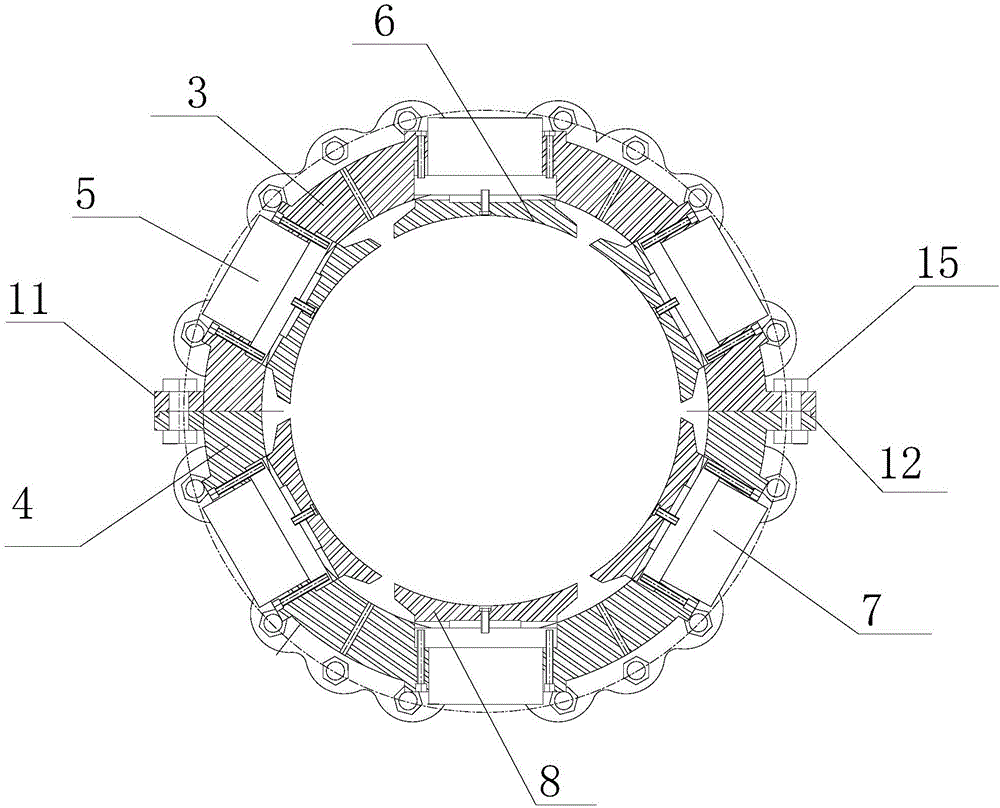

[0019] refer to figure 1 , figure 2 , the present invention proposes a cylindrical horizontal coal mine shaft engineering physical simulation test device, including a confining pressure loading mechanism, a loading end cap 1, a restraining end cap 2, a hydraulic operation and a control mechanism, wherein:

[0020] The confining pressure loading mechanism includes multiple groups of confining pressure loading units fixed in sequence, and in this embodiment, the confining pressure loading mechanism includes 5 confining pressure loading units. Each confining pressure loading unit includes a first confining pressure arc plate 3 and a second confining pressure arc plate 4, the first confining pressure arc plate 3 and the second confining pressure arc plate 4 are semicircular and the first confining pressure arc plate 3 The diameter of the second confining arc plate 4 is equal, the openings of the first confining arc plate 3 and the second confining arc plate 4 are opposite, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com