Fixation and installation method of embedded iron parts

A technology of pre-embedding iron parts and installation methods, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems that affect the precise positioning of iron parts and do not meet the needs, and achieve cost saving, accurate positioning and installation, and high tonnage big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings.

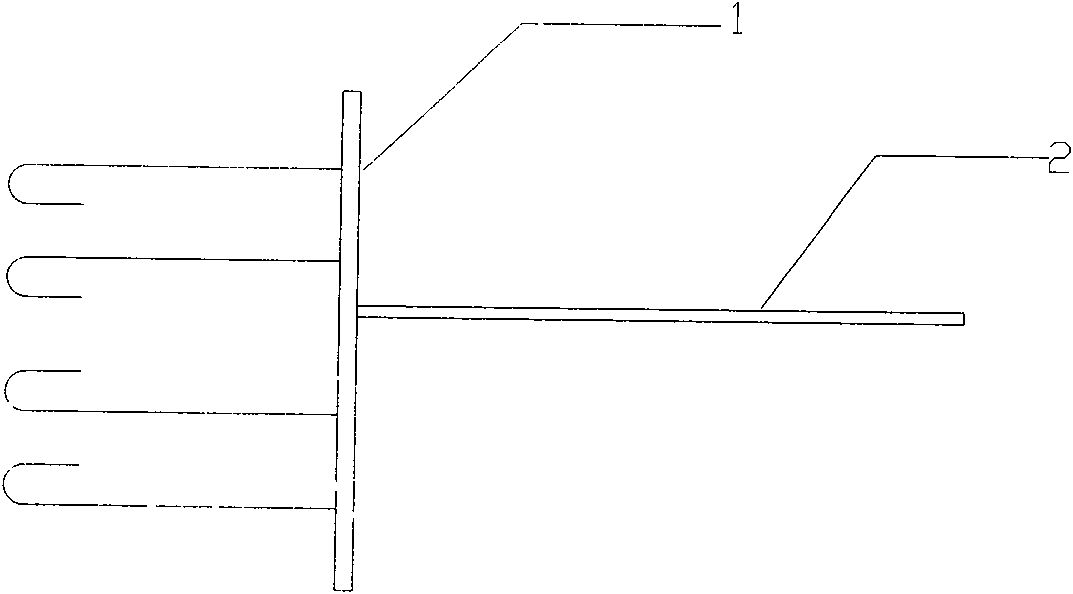

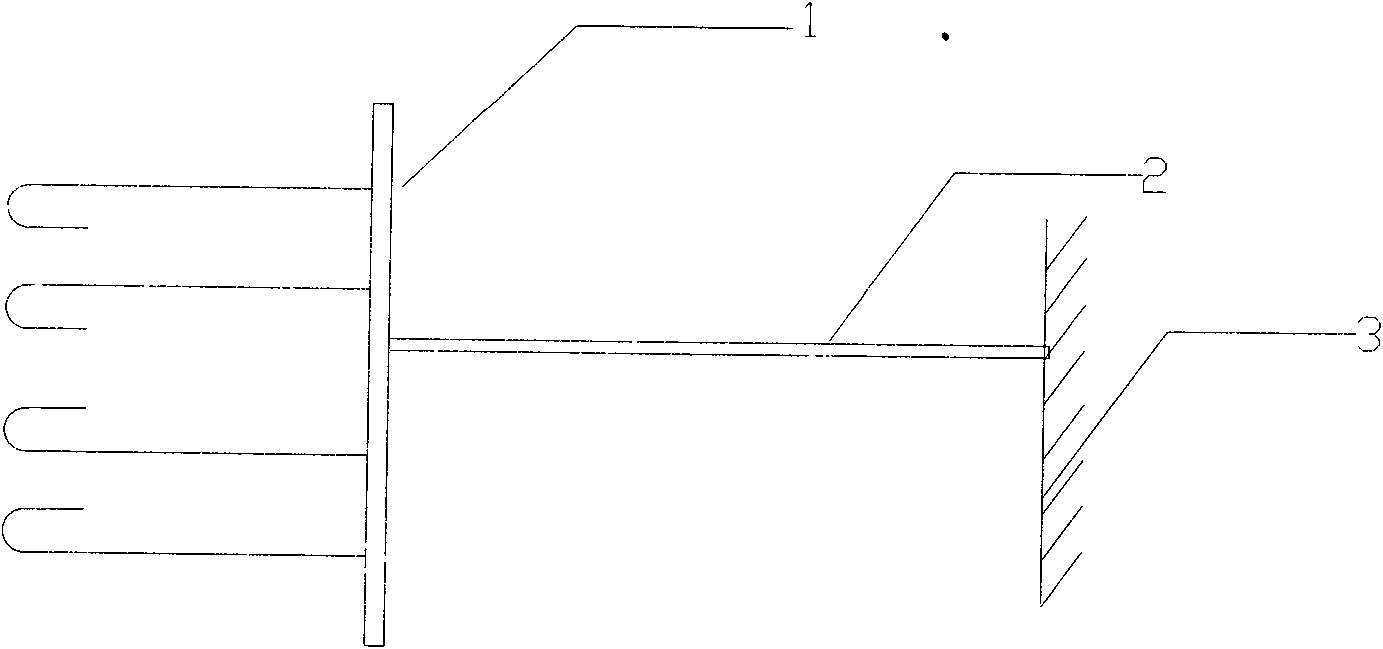

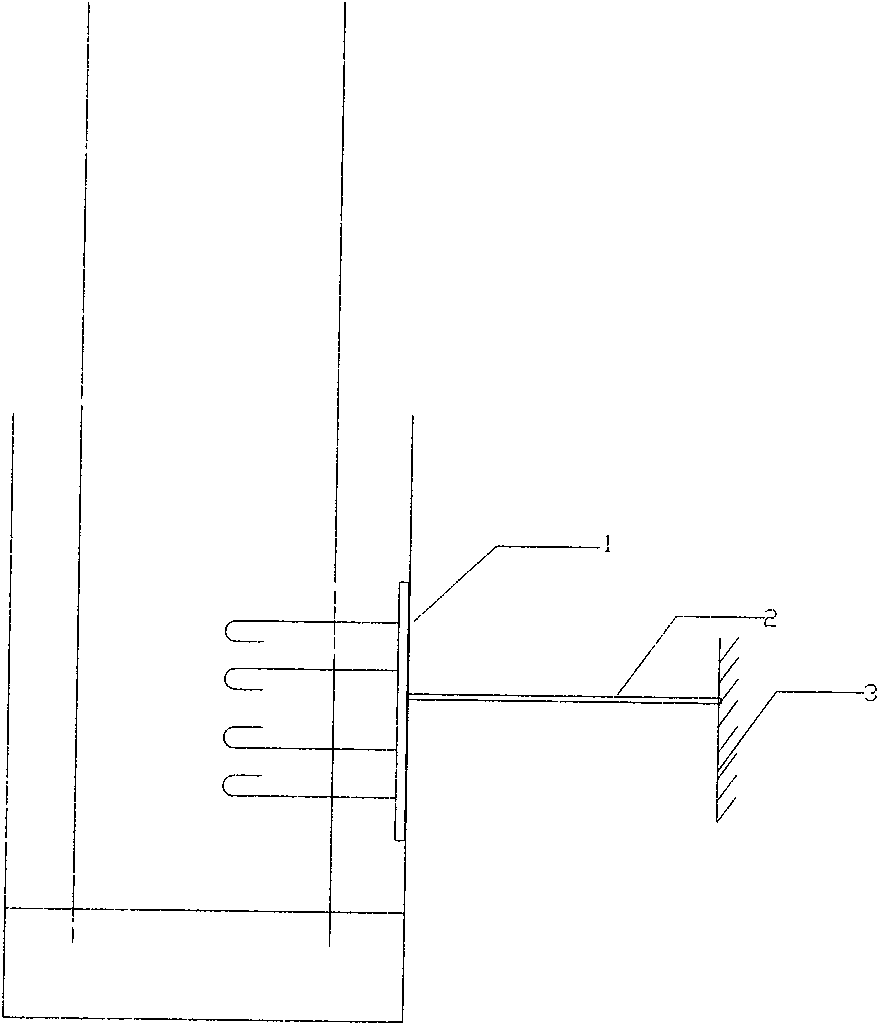

[0012] The present invention carries out according to the following steps: (1), weld steel pipe or reinforcing bar as connecting rod 2 at the front face of embedded iron part 1, as figure 1 As shown, the embedded iron part 1 is fixed by connecting the connecting rod 2 with the external stable body 3, as shown in figure 2 As shown; (2), according to the conventional method, tie the reinforcement and seal the mold around the embedded iron part 1, such as image 3 As shown, concrete is poured, and after the concrete reaches strength, the formwork is removed and the connecting rod 2 is cut off, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com