Self-adaptively assembled large-diameter nuclear power wedge-shaped gate valve and mounting method

A wedge gate valve and large-diameter technology, which is applied in the field of large-diameter nuclear power wedge gate valve and installation, to achieve fast and accurate positioning and installation, and to ensure effective fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

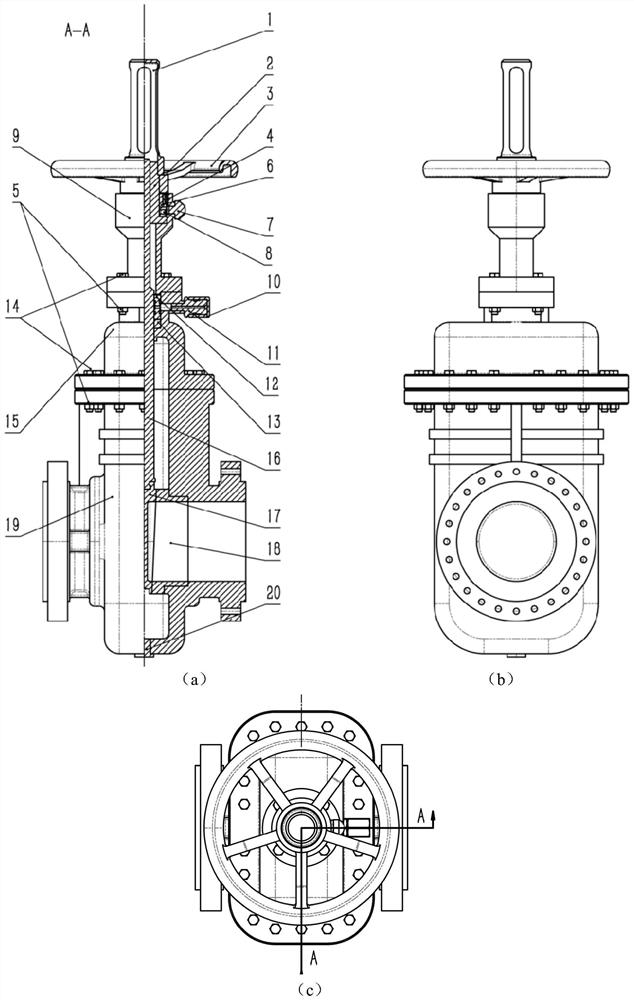

[0056] Below in conjunction with accompanying drawing, the present invention is described in more detail:

[0057] The overall structure diagram of large-diameter nuclear power gate valve is as follows figure 1 As shown, the gate valve includes a valve cover 1, a valve stem nut 2, a hand wheel 3, an external thread locking nut 4, a hexagonal nut 5, a valve stem nut sleeve 6, an oil cup 7, a thrust ball bearing 8, a bracket 9, Grease injection valve cover 10, grease injection valve 11, sealing frame 12, sealing frame gasket 13, hexagon bolt 14, valve cover 15, valve stem 16, gate 17, sealing seat 18, valve body 19, and drain plug 20.

[0058] The third part of the bolt hole on the outside of the valve cover 15 and the bolt hole on the upper end of the valve body 19 are tightly connected by the hexagonal bolt 14 and the hexagonal nut 5; the inner flow channel surface of the valve body 19 and the narrow end of the sealing seat 18 are tightly fitted by the shrink fit method Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com