Patents

Literature

47results about How to "Large tonnage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

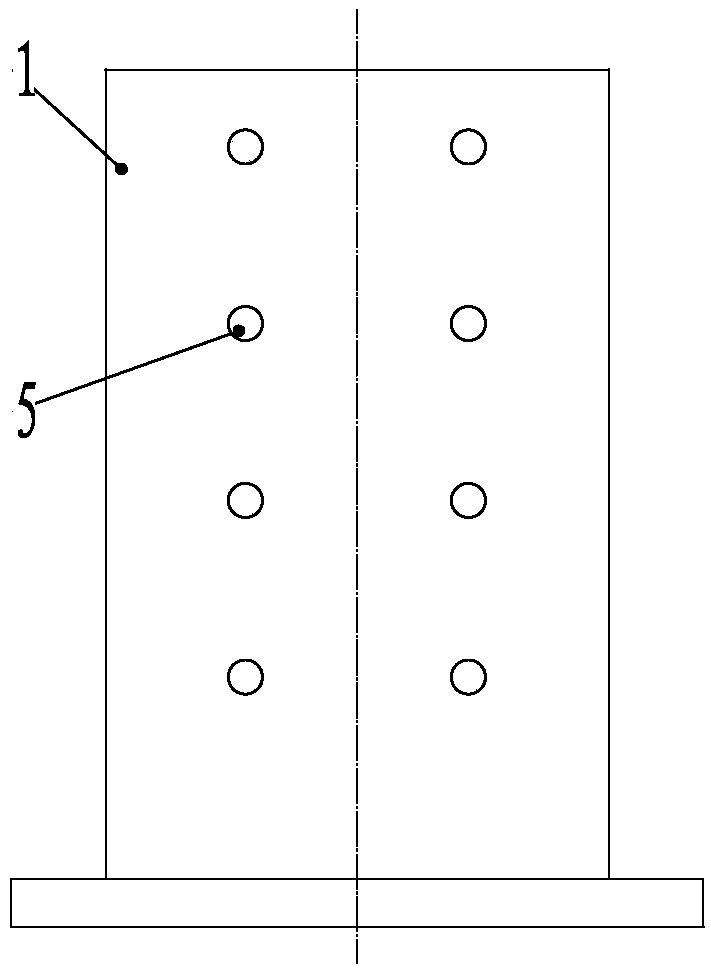

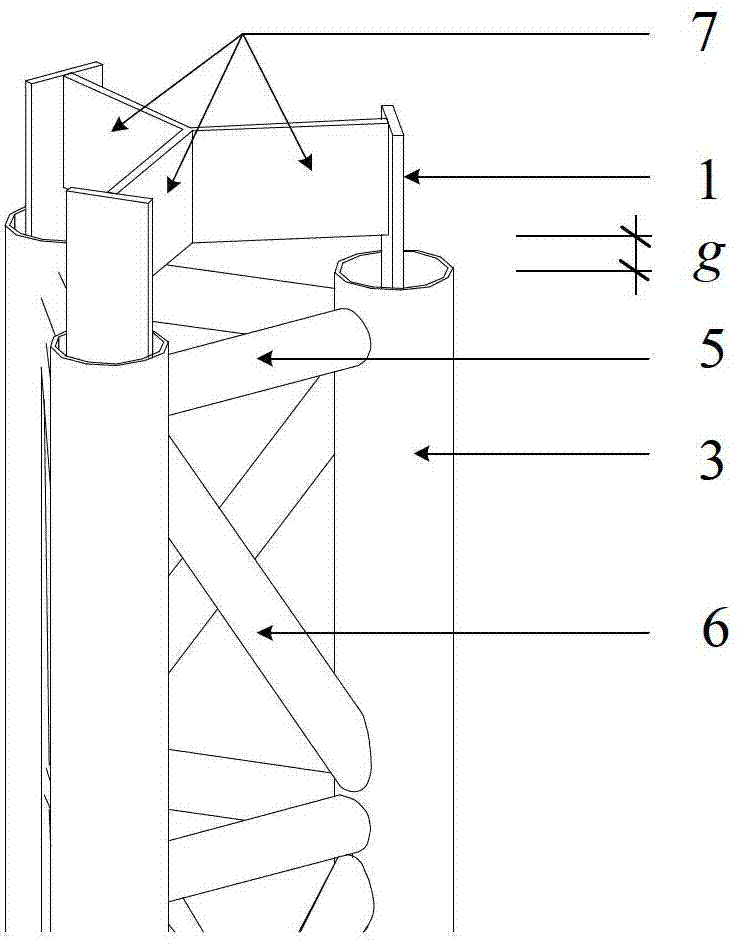

Anti-buckling supporting member with lattice type double-rectangular-pipe cross section

InactiveCN103410240AIncrease the moment of inertiaIncreased bending stiffnessShock proofingWeld seamBending moment

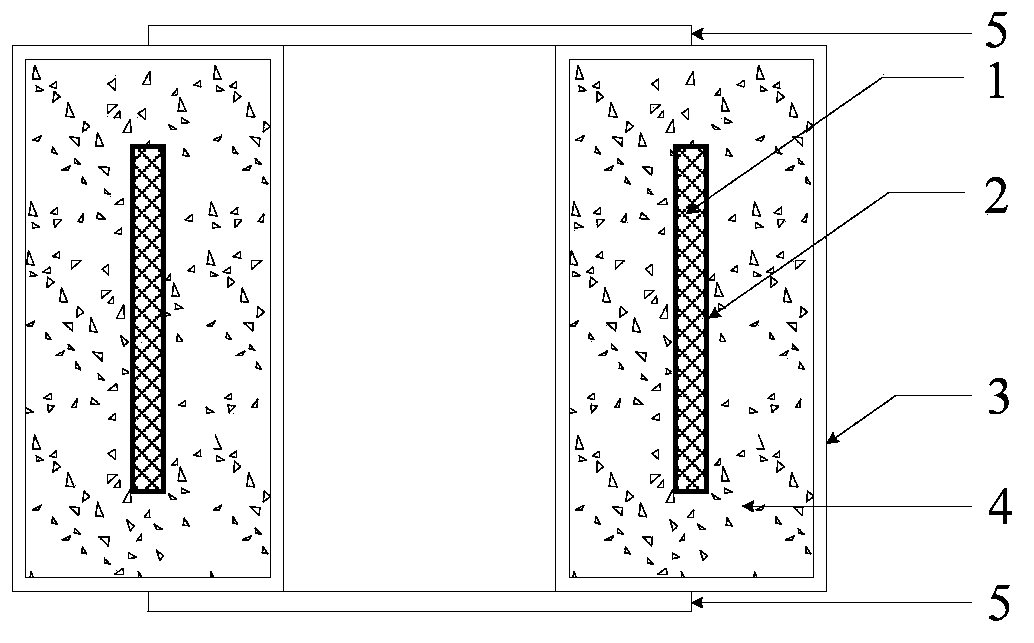

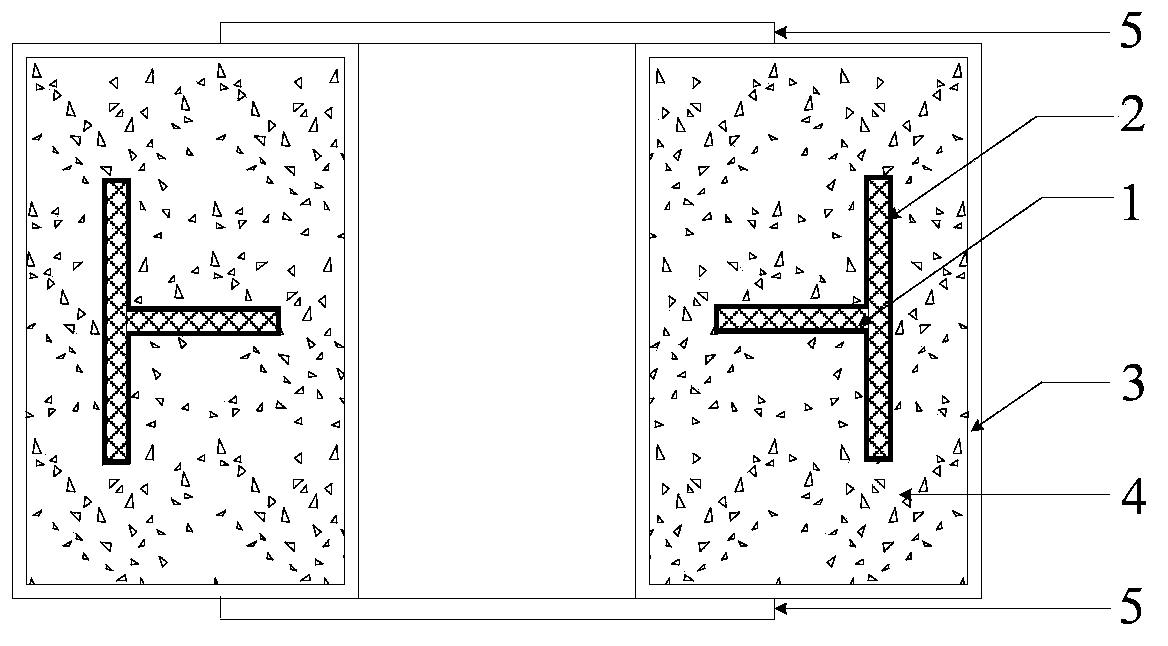

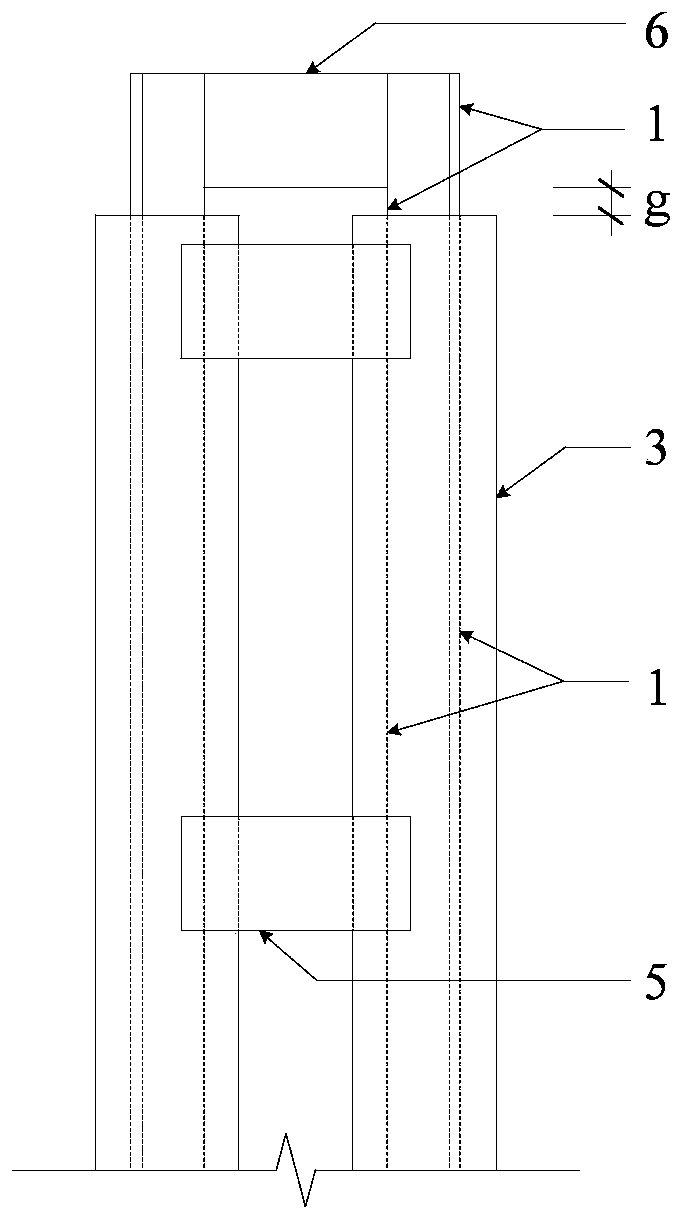

An anti-buckling supporting member with a lattice type double-rectangular-pipe cross section comprises two anti-buckling branches which are connected through a plurality of steel batten plates, wherein each branch adopts an anti-buckling supporting member provided with a linear core and a restraint concrete-filled rectangular steel pipe; long edges of the two branches are parallelly arranged at appropriate intervals, a lattice type member formed by connecting the plurality of steel batten plates which are distributed longitudinally is taken as a whole for common work, the steel batten plates and branch short edges, namely short edges of the restraint rectangular steel pipes, are in welded connection through trihedral angle welding seams; and end parts of the linear cross section cores of the two branches extend out of circumferential restraint members, and are connected through a ribbed plate to form an H-shaped cross section which can be connected with a frame member through a high-strength bolt and a connecting plate. The lattice type cross section can increase inertia moment of the whole cross section of the anti-buckling supporting member and the whole flexural rigidity, thereby particularly suitable for a design of a large-tonnage anti-buckling support member, the support end part is conveniently connected with the frame member, and the lower branch still can sufficiently play energy-dissipating capacity when eccentric bending moment is added.

Owner:TSINGHUA UNIV

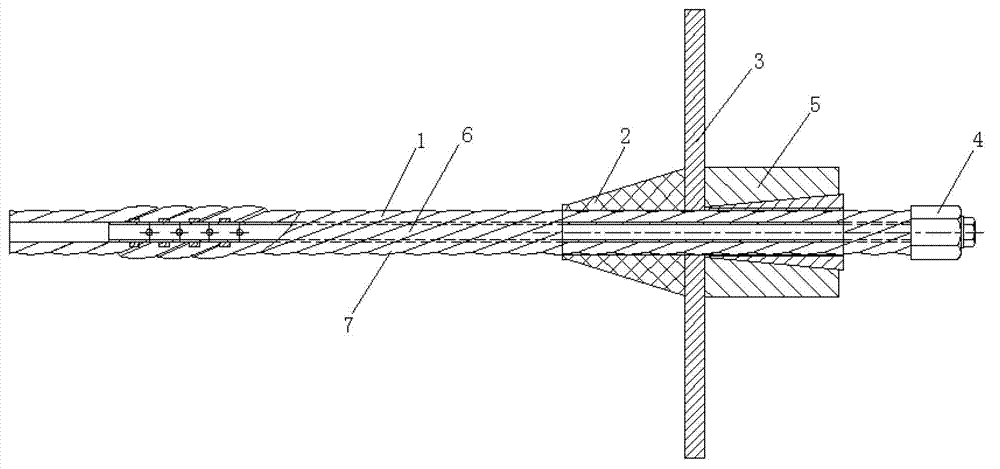

Pre-stress spiral rib hollow grouting anchor rope

The invention discloses a pre-stress spiral rib hollow grouting anchor rope which comprises an anchor rope body which stretches into a rock-soil drilling hole; the anchor rope body is formed by weaving and twisting a plurality of high-strength spiral rib pres-stress steel wires; a rope tool is fixedly connected with the rear end of the anchor rope body; a grouting core tube penetrates through the anchor rope body and the anchor tool; a support disc is sleeved on the anchor tool; a locking nut is screwed on the anchor tool at the rear end of the support disc; the locking nut props against the rear end face of the support disc; and a slurry stopping plug which aligns with the rock-soil drilling hole is sleeved at the rear end of the anchor rope body. According to the grouting anchor rope, by increasing the grouting pressure, while being filled into the drilling hole so as to realize the overall-length anchoring, slurry spreads into the rock fractures around the drilling hole at the same time, so that the bonding and curing functions to the surrounding rock are achieved, and the deep hole anchoring grouting is realized.

Owner:淮南市顺辉锚固有限公司

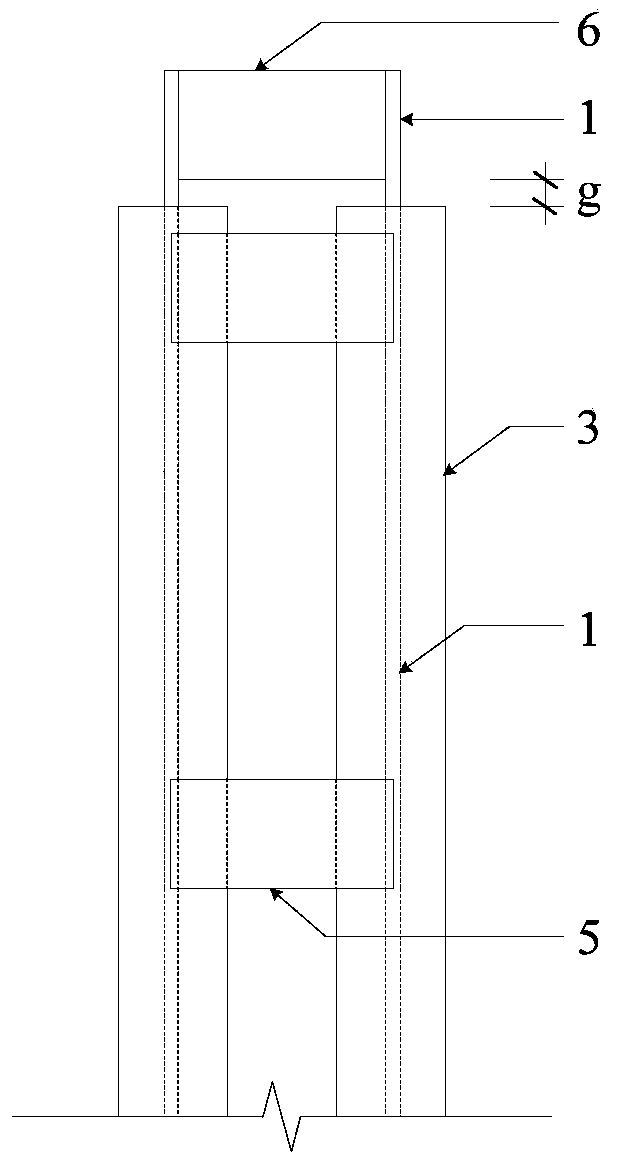

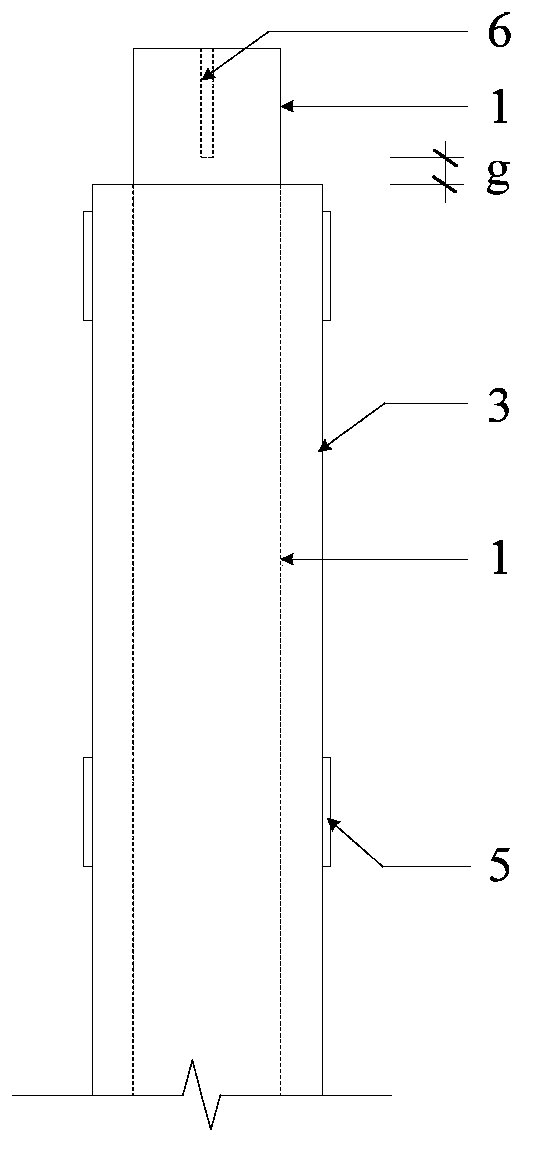

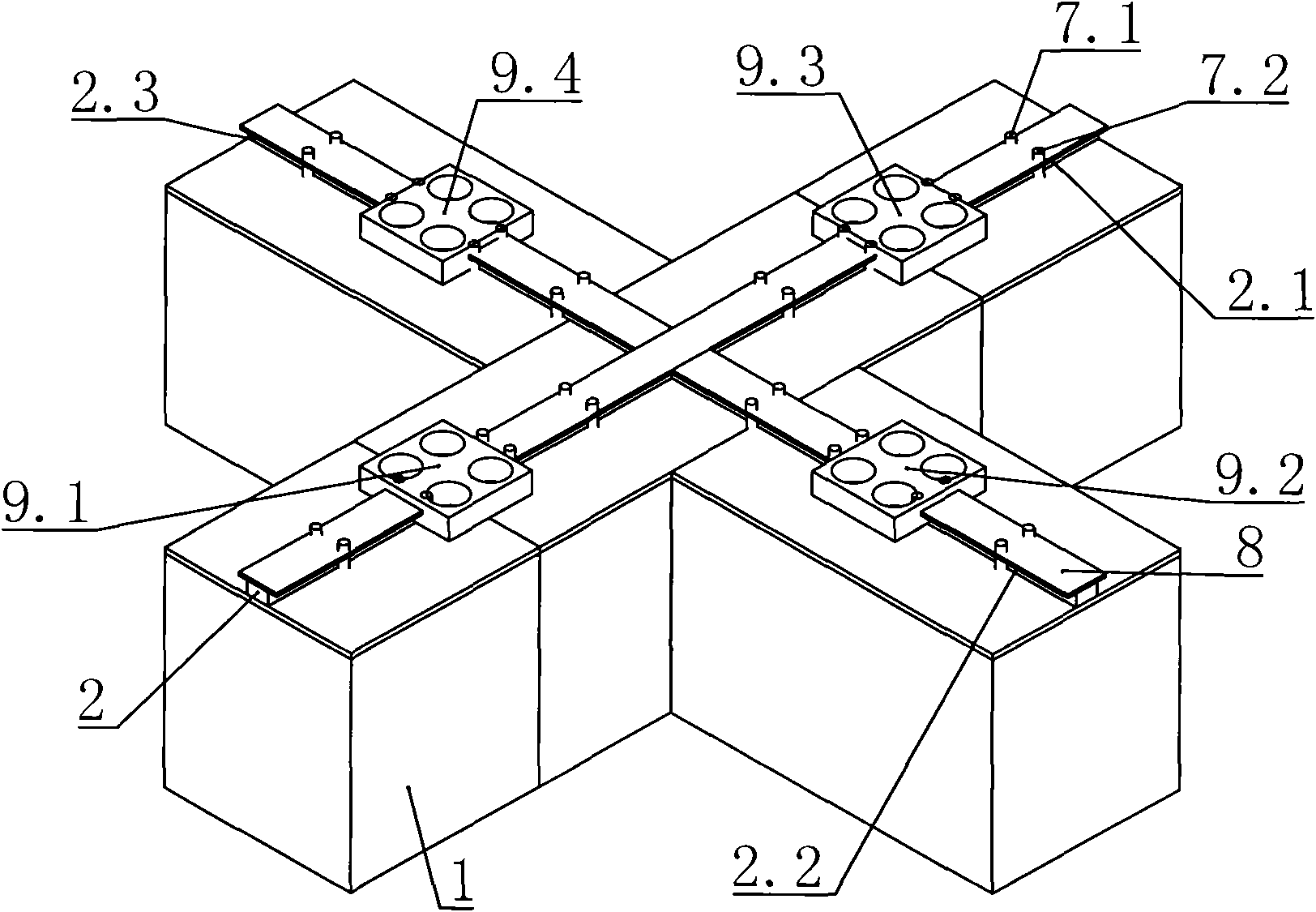

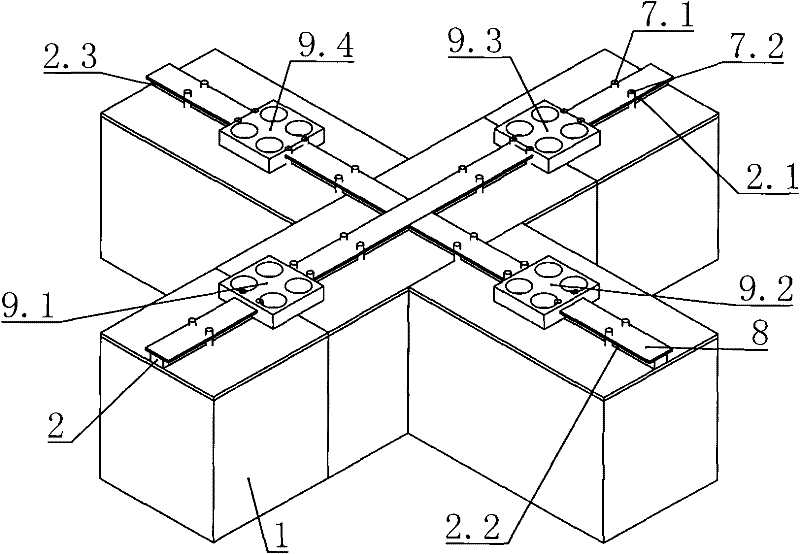

Detachable tower foundation

The invention belongs to the technical field of building equipment, and provides a detachable tower foundation. The main characteristics are that the tower foundation comprises a base seat and a beam; the base seat is a crossed channel steel base seat formed by a centre base seat and four side base seats connected with the four sides of the centre base seat; a support member is arranged in the base seat; a crossed steel beam in the same shape as the base seat is arranged on and fixedly connected with the base seat; and a tower-crane base seat is correspondingly arranged on the upper surface of the steel beam. Compared with the existing disposable tower foundation and the prior detachable power foundation, the invention has the advantages of easy mounting and detachment, convenient transportation, repeatable use, reduced building cost, and the like.

Owner:陈金生

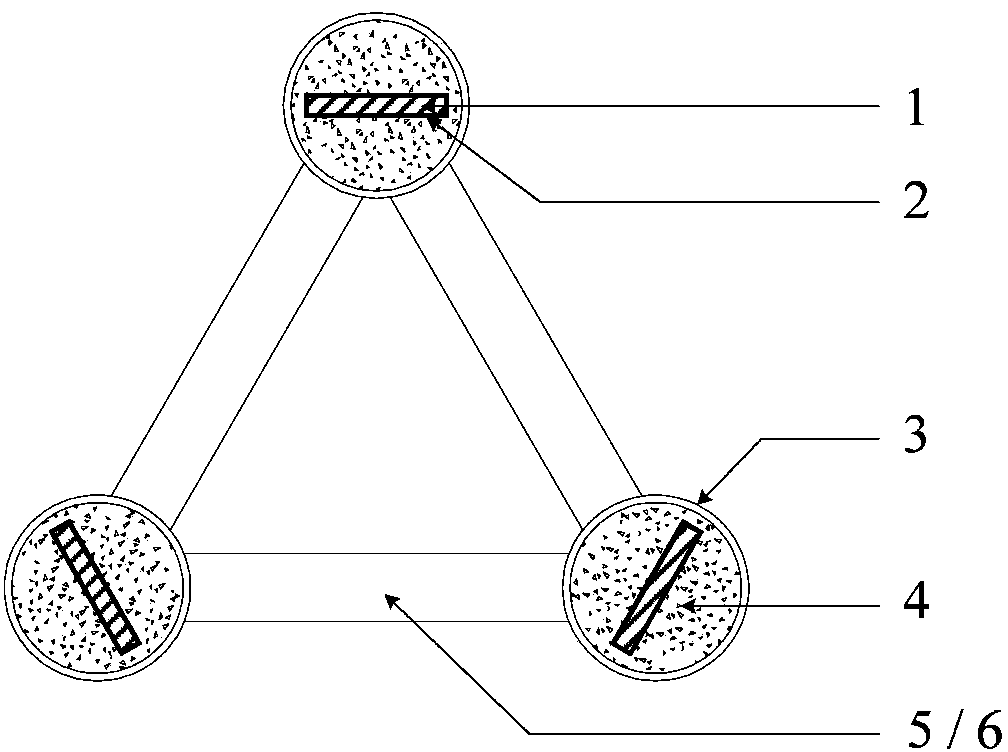

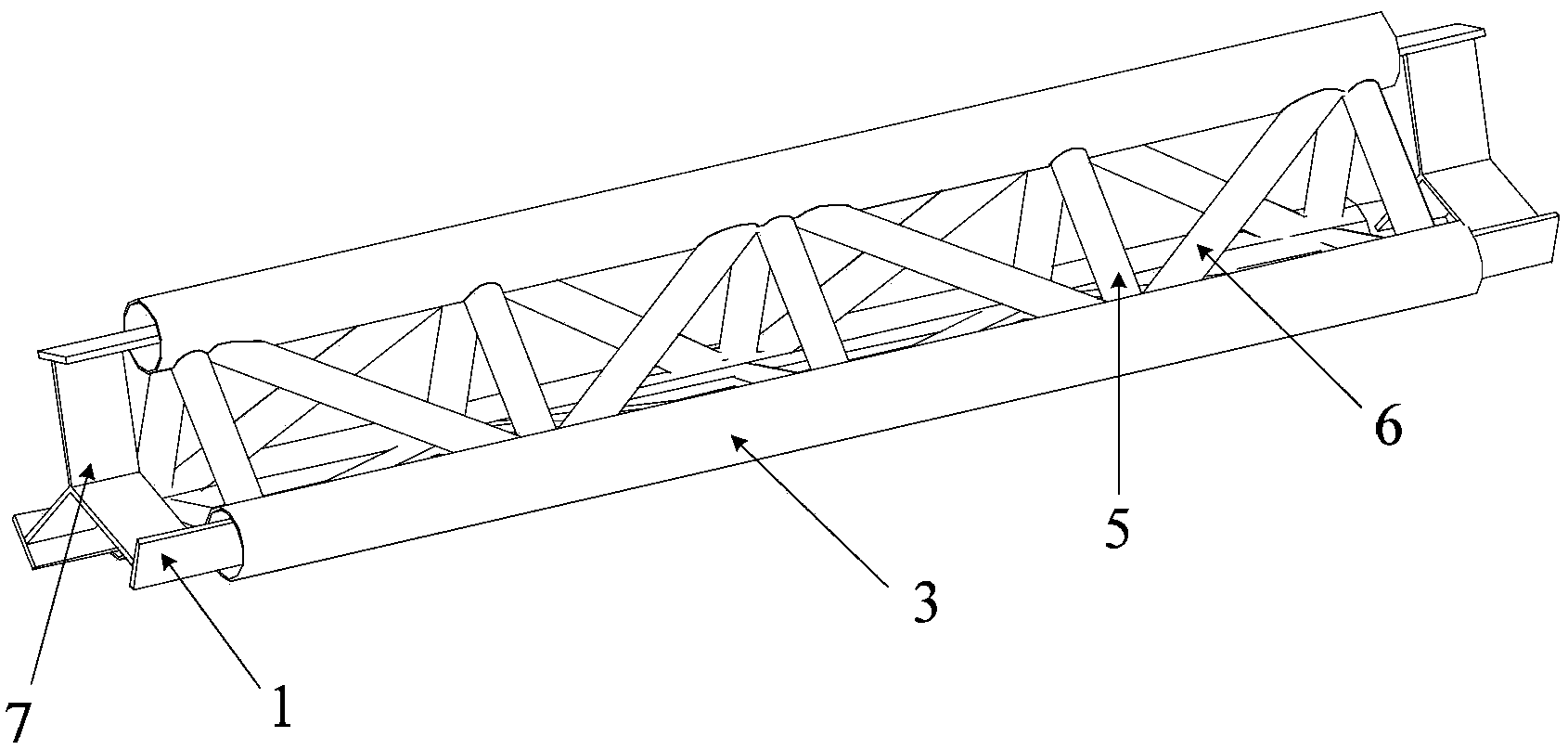

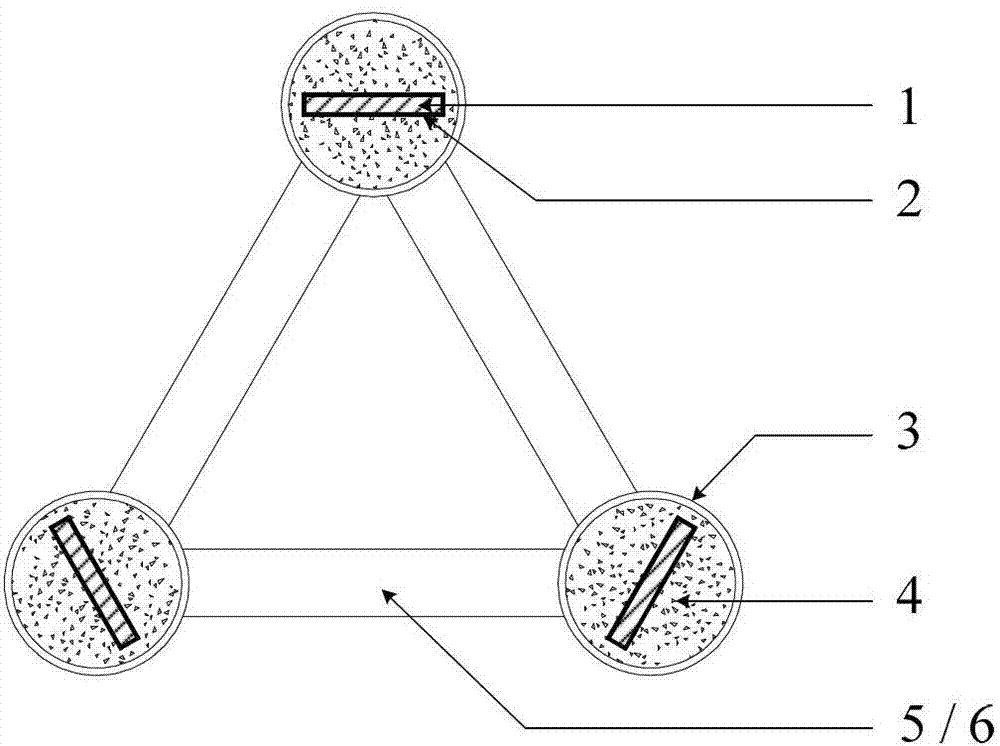

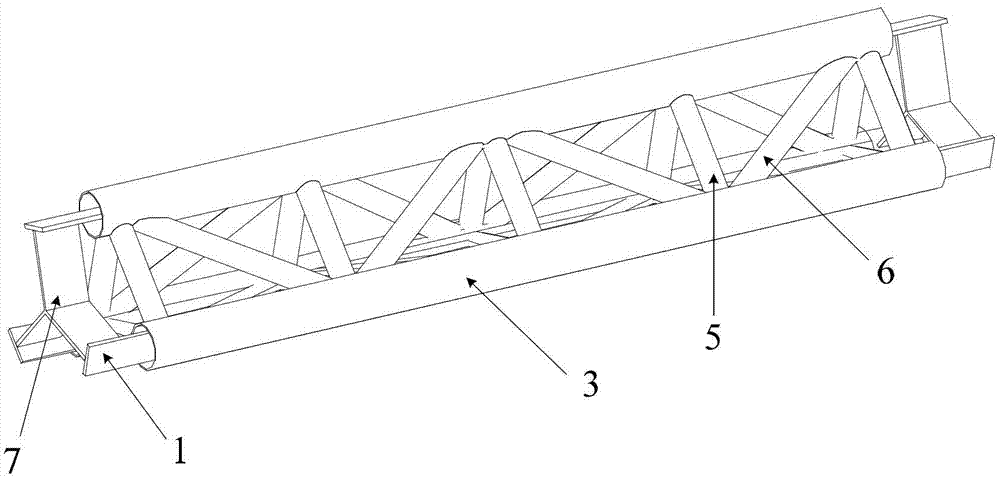

Anti-buckling supporting member with lattice type three-circular-pipe cross section

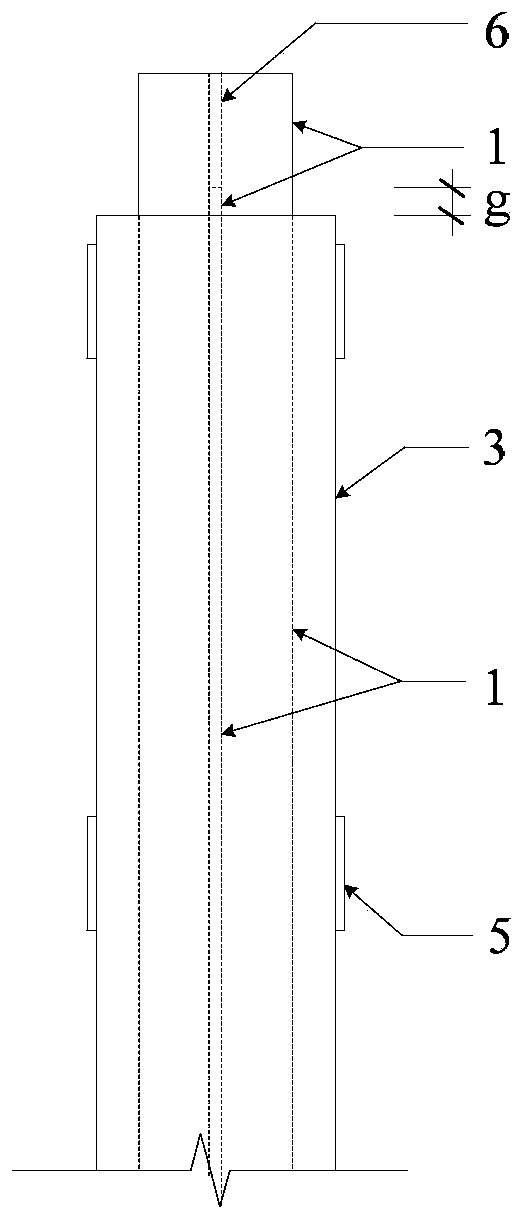

An anti-buckling supporting member provided with a lattice type three-circular-pipe cross section comprises three anti-buckling branches which are connected through batten pieces of inclined batten pipes, transverse batten pipes and the like as well as end ribbed plates, wherein each anti-buckling branch adopts an anti-buckling supporting member provided with a linear core and a concrete-filled restraint circular steel pipe; the three anti-buckling branches have the same sizes, are parallelly arranged to form a regular-triangle cross section, and are connected through the transverse batten pipes and the inclined batten pipes to form a lattice type member; and the transverse batten pipes and the inclined batten pipes are connected with the constraint circular steel pipes of the anti-buckling branches through intersecting weld. End parts of the linear core members of the three anti-buckling branches extend out of the circumferential constraint circular steel pipes, a ribbed plate is vertically welded at the externally extending section of each core, and the three ribbed plates are interested to the center of the regular triangle and welded to be a whole, so that end nodes of the anti-buckling supporting member are formed. The lattice type cross section facilitates improvement of the bearing efficiency of the anti-buckling supporting member, can remarkably reduce the weight of the member, and meets the design requirement of large-tonnage and ultra-long anti-buckling support in structures of a giant frame and the like.

Owner:TSINGHUA UNIV

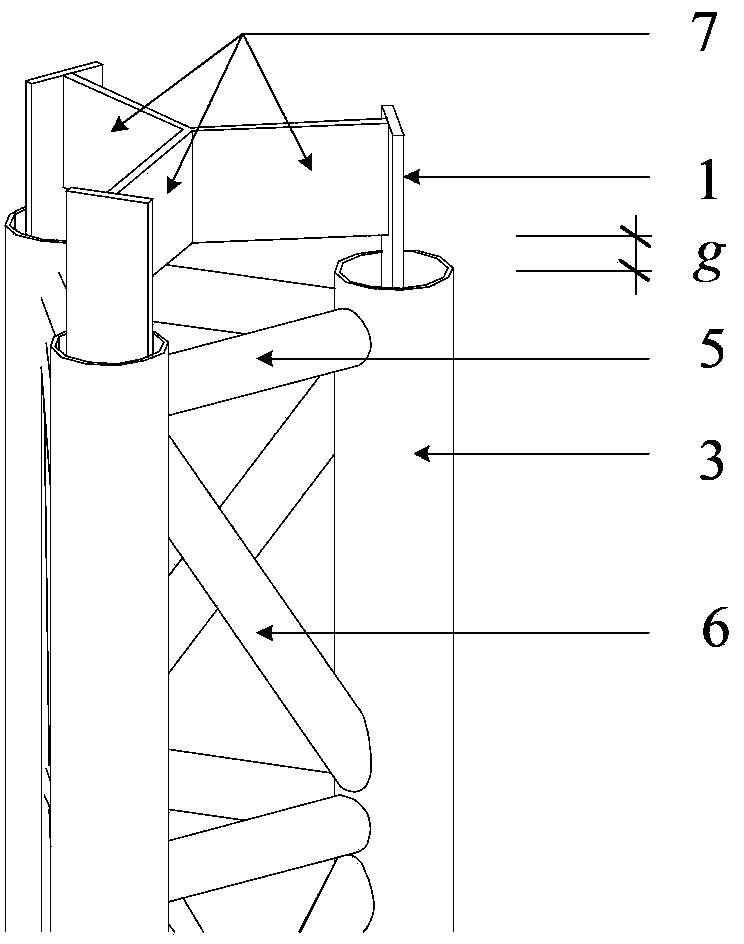

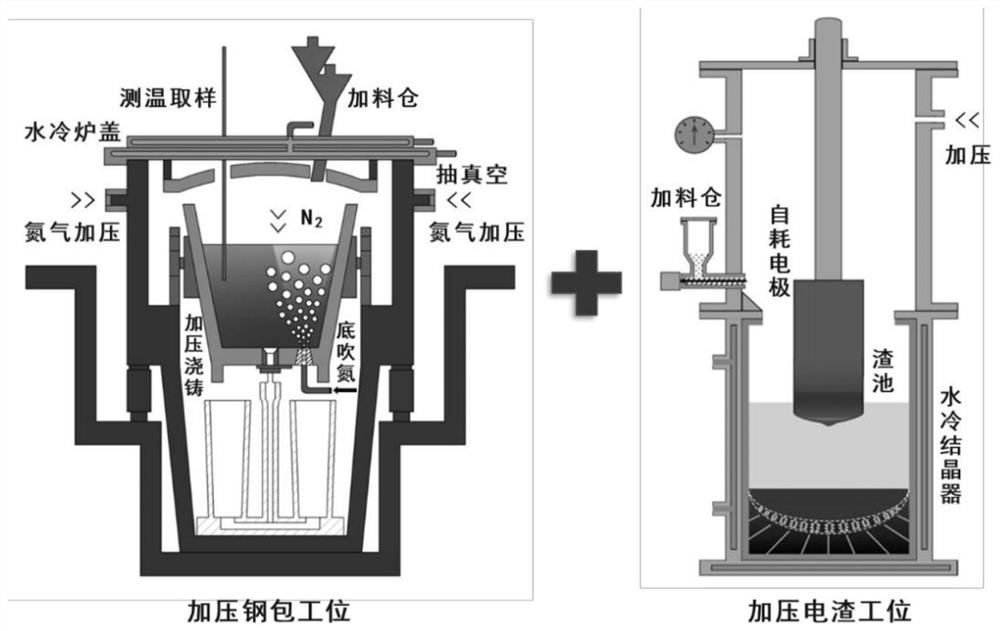

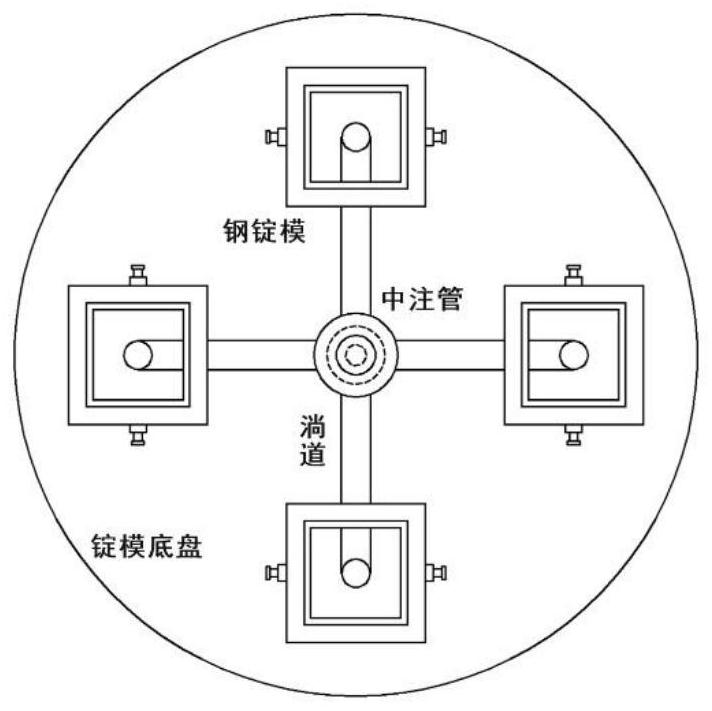

Method for duplex smelting for high-nitrogen steel through pressurized ladle refining and pressurized electroslag remelting

ActiveCN112899438AWide variety of sourcesFlexible in seriesIncreasing energy efficiencyPetrochemicalMolten steel

The invention provides a method for duplex smelting for high-nitrogen steel through pressurized ladle refining and pressurized electroslag remelting, and belongs to the technical field of high-nitrogen steel smelting. According to the invention, nitrogen alloying, deep deoxidation and deep desulfurization are sequentially carried out on molten steel in a pressurized steel ladle, and meanwhile, efficient nitrogen alloying is realized in the nitrogen alloying process in the mode that nitrogen bottom-blowing and pressurized gas phase-molten steel interface nitriding are combined, so that nitrogen is uniformly distributed, and the content of impurities in the molten steel is reduced through nickel-magnesium alloy and rare earth; and then the pressurized electroslag remelting is carried out, so that the content of inclusions and impurity elements in the molten steel is further reduced, segregation of the steel is improved, and the high-nitrogen steel is uniform and compact in structure. The result of the embodiment shows that the high-nitrogen steel is low in impurity content, uniform and stable in component and capable of meeting the use requirements in the fields of aviation, aerospace, petroleum, chemical engineering, energy, ocean, bioengineering and the like.

Owner:NORTHEASTERN UNIV LIAONING

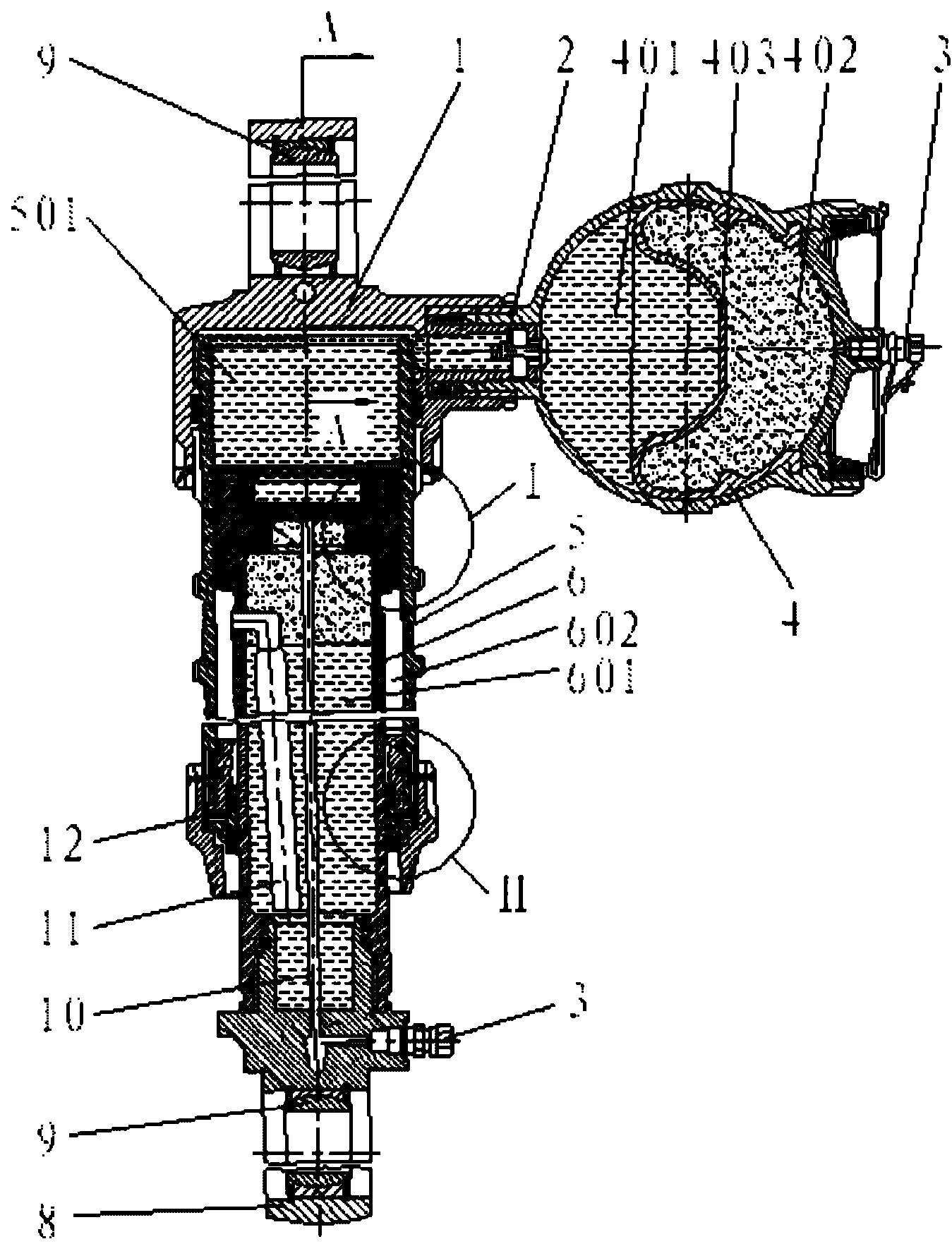

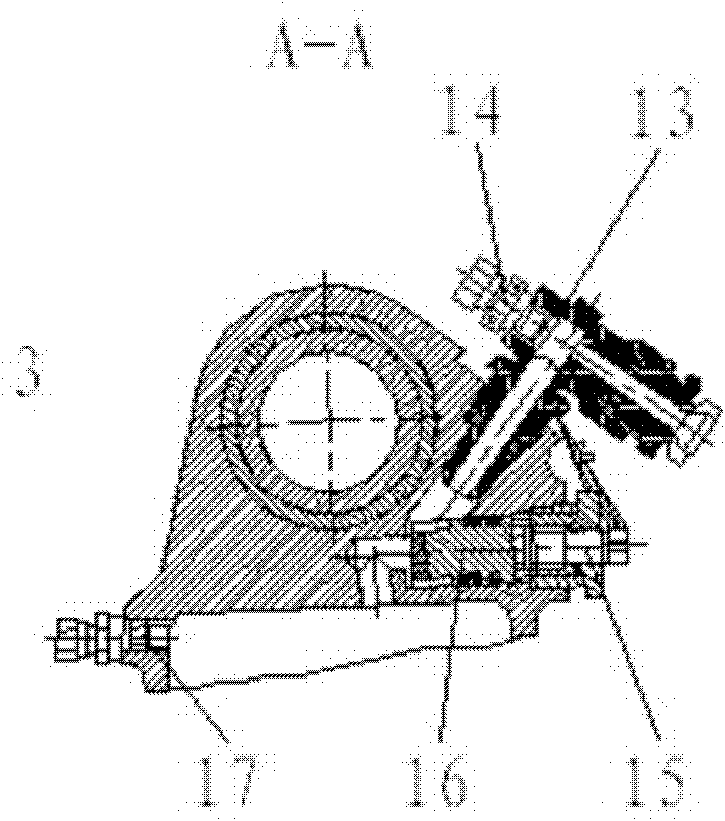

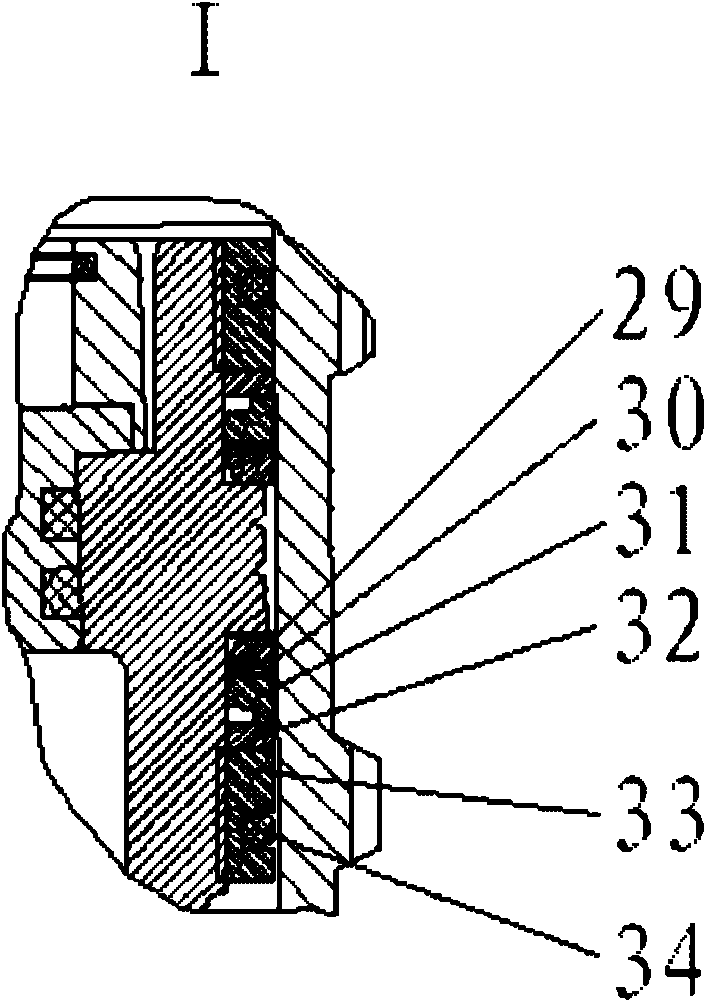

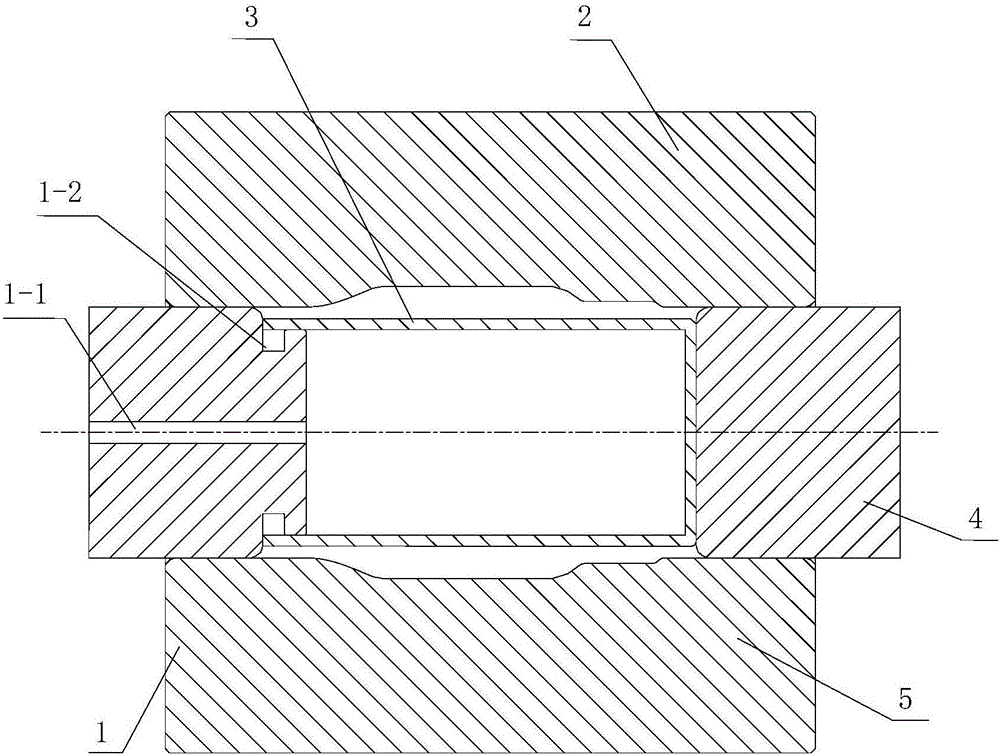

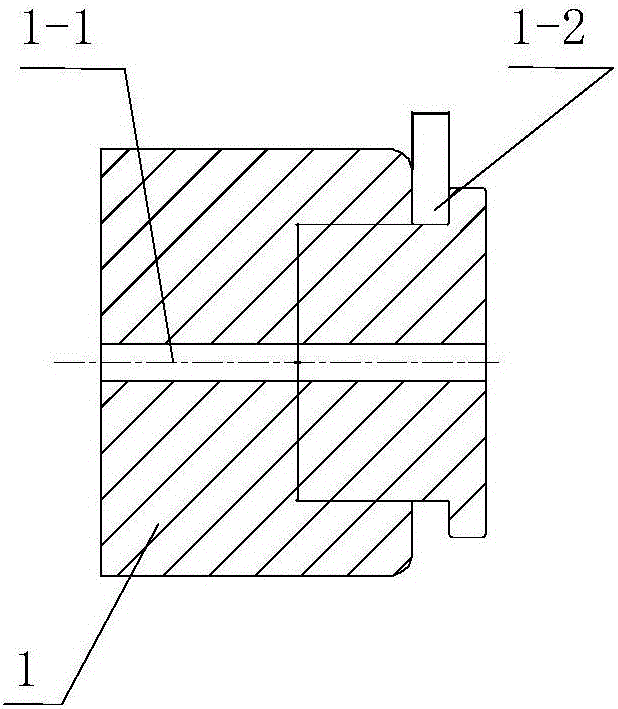

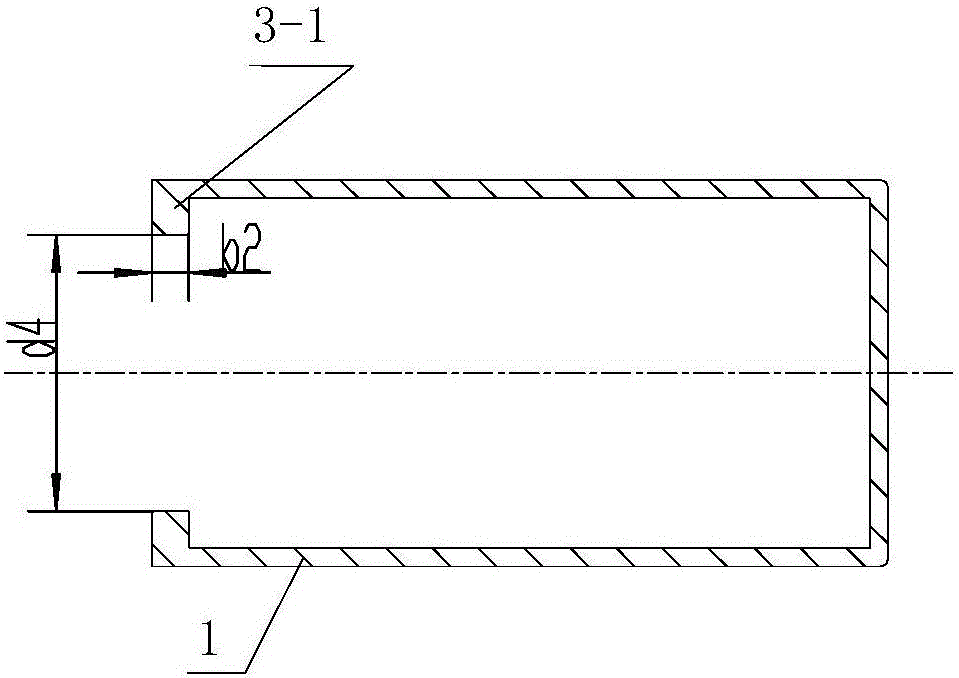

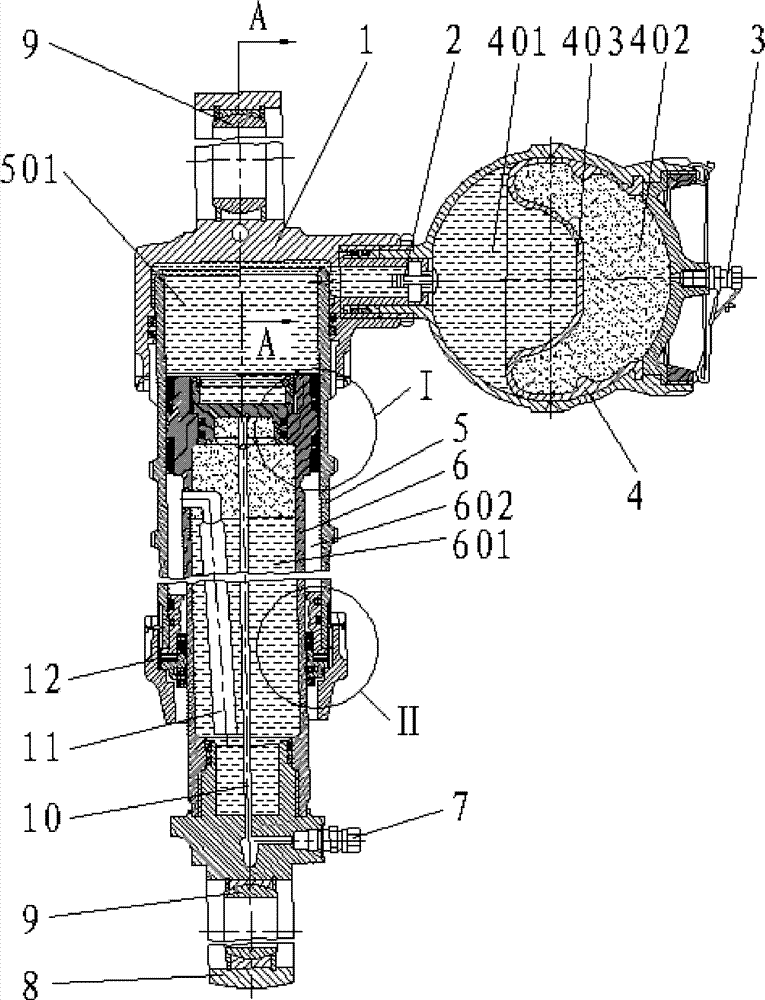

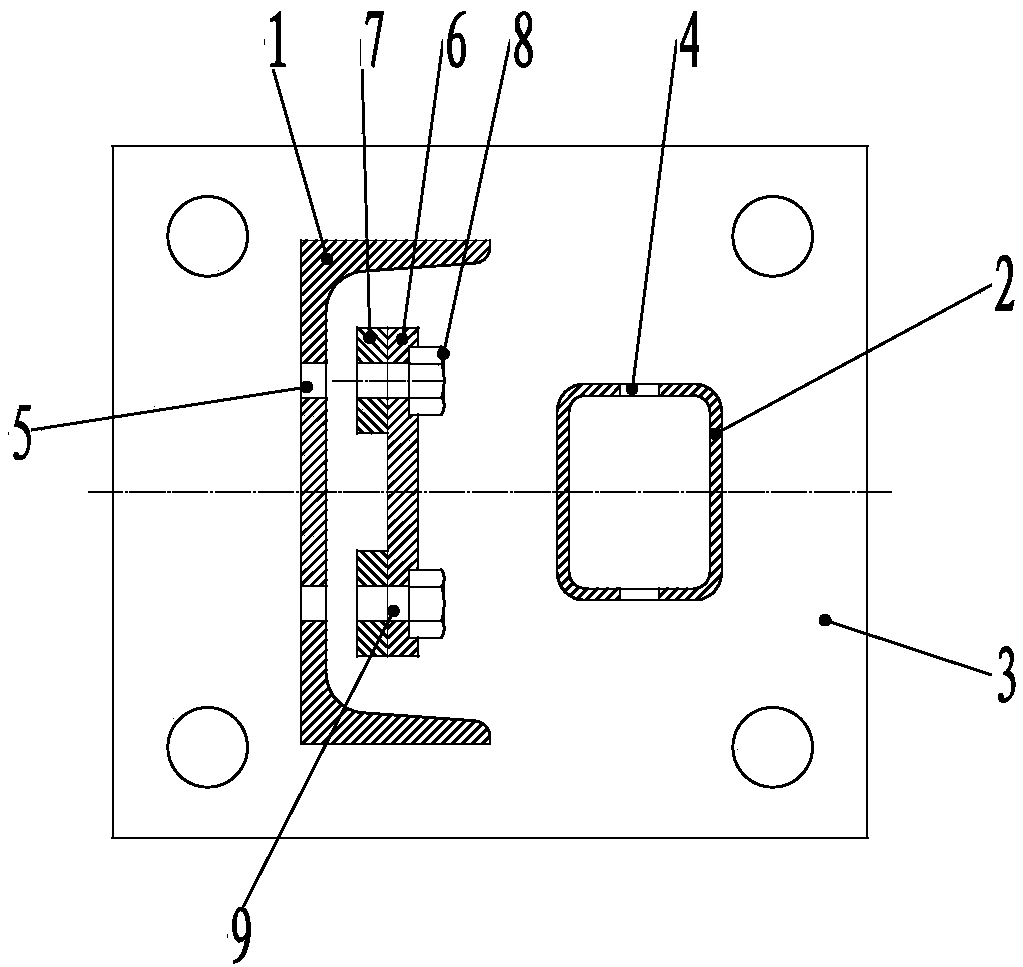

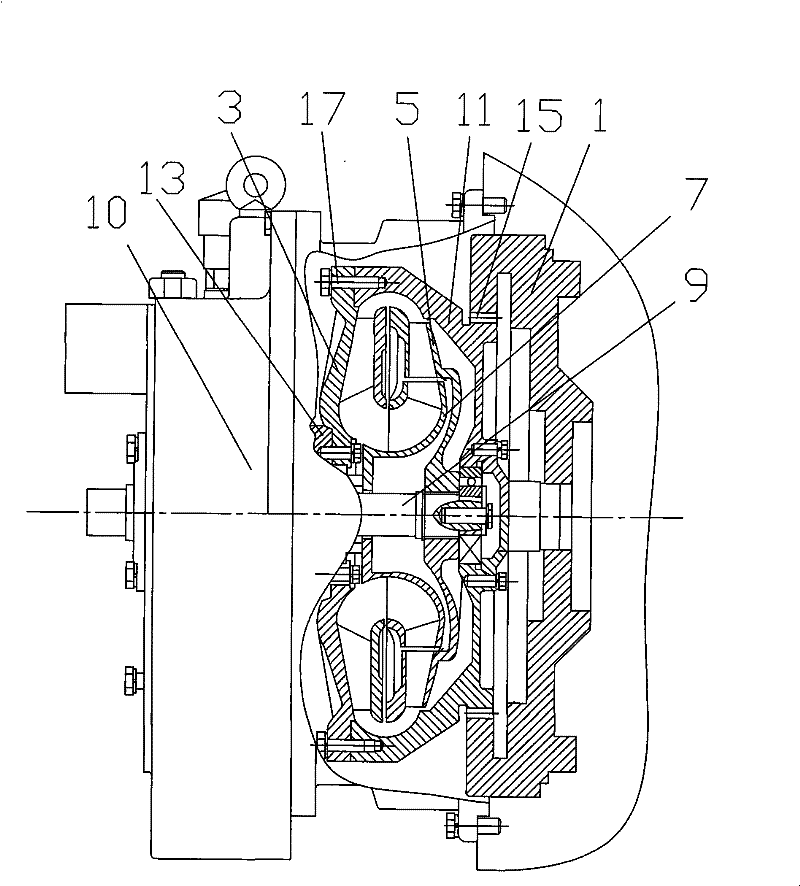

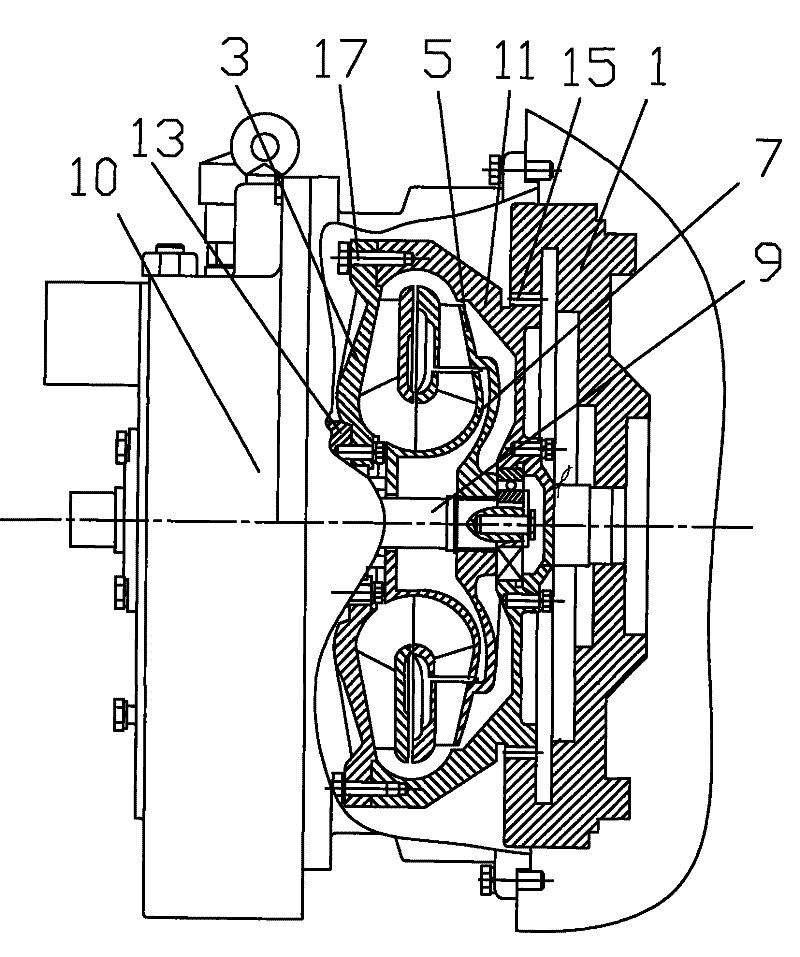

Double-chamber hydragass spring

ActiveCN102121508AImprove sealingEasy maintenanceSpringsGas and liquid based dampersElastic componentEngineering

The invention relates to a double-chamber hydragass spring which comprises an upper lug, a lower lug, a main cylinder, an elastic component, a back pressure cylinder, a piston, a guide pipe and the like, wherein the upper lug is positioned at the upper part of the main cylinder; the lower lug is positioned at the lower part of the back pressure cylinder, the upper lug and the main cylinder are connected through a thread structure, and the lower lug and the back pressure cylinder are connected through a thread structure; the upper lug and the lower lug are both provided with a bearing internally; the side part of the upper lug is connected with the elastic component; and the piston and the guide pipe are installed in the back pressure cylinder. The double-chamber hydragass spring is characterized in that the back pressure cylinder, the piston and the guide pipe are connected into a whole and installed in the cylinder body of the main cylinder; a main cavity is formed by a space among the upper surface of the piston, the main cylinder and the space below the upper lug; a main air chamber is formed by the main cavity, an elastic component oil liquid chamber of the elastic component and an air chamber; a back pressure air chamber is formed by a back pressure chamber in the back pressure cylinder and a ring chamber positioned between the main cylinder and the back pressure cylinder; the back pressure chamber and the ring chamber are connected through a connecting pipe. The double-chamber hydragass spring has the beneficial effects of simple structure, small size, light weight, good tightness and large bearing tonnage and is convenient to arrange and install.

Owner:中国航天三江集团公司特种车辆技术中心

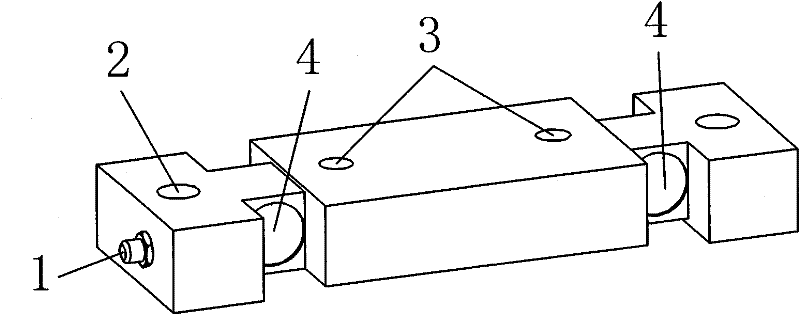

Forming tool and forming method for circumferential non-closed variable-cross-section cylindrical part

ActiveCN106345953AImprove machining accuracyIncrease profitForging/hammering/pressing machinesManufacturing cost reductionMachining

The invention relates to a forming tool and a forming method for a circumferential non-closed variable-cross-section cylindrical part. The forming tool is characterized by comprising a first sealing head, a second sealing head, a liquid filling bag, an upper die and a lower die, wherein the first sealing head is provided with a liquid inlet and an annular groove, one end of the liquid filling bag is an open end, the open end is provided with a sealing flange, the open end of the liquid filling bag is arranged on the first sealing head in a sleeving mode and is embedded into the groove of the first sealing head through the sealing flange, and the liquid filling bag is located in the die cavity formed by the first sealing head, the second sealing head, the upper die and the lower die. The forming tool has the advantages that peculiar shaped part forming machining can be simplified, the material and device utilization rate and the forming part machining precision are remarkably improved, and the manufacturing costs are reduced. Blanks used by the forming method can be circumferentially closed tubular products or cylindrical parts and can be also a circumferentially opened tubular blanks having a certain overlapping amount or planar plates, and a machining application range is wide.

Owner:天津天锻航空科技有限公司

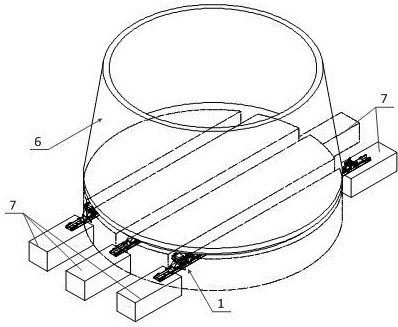

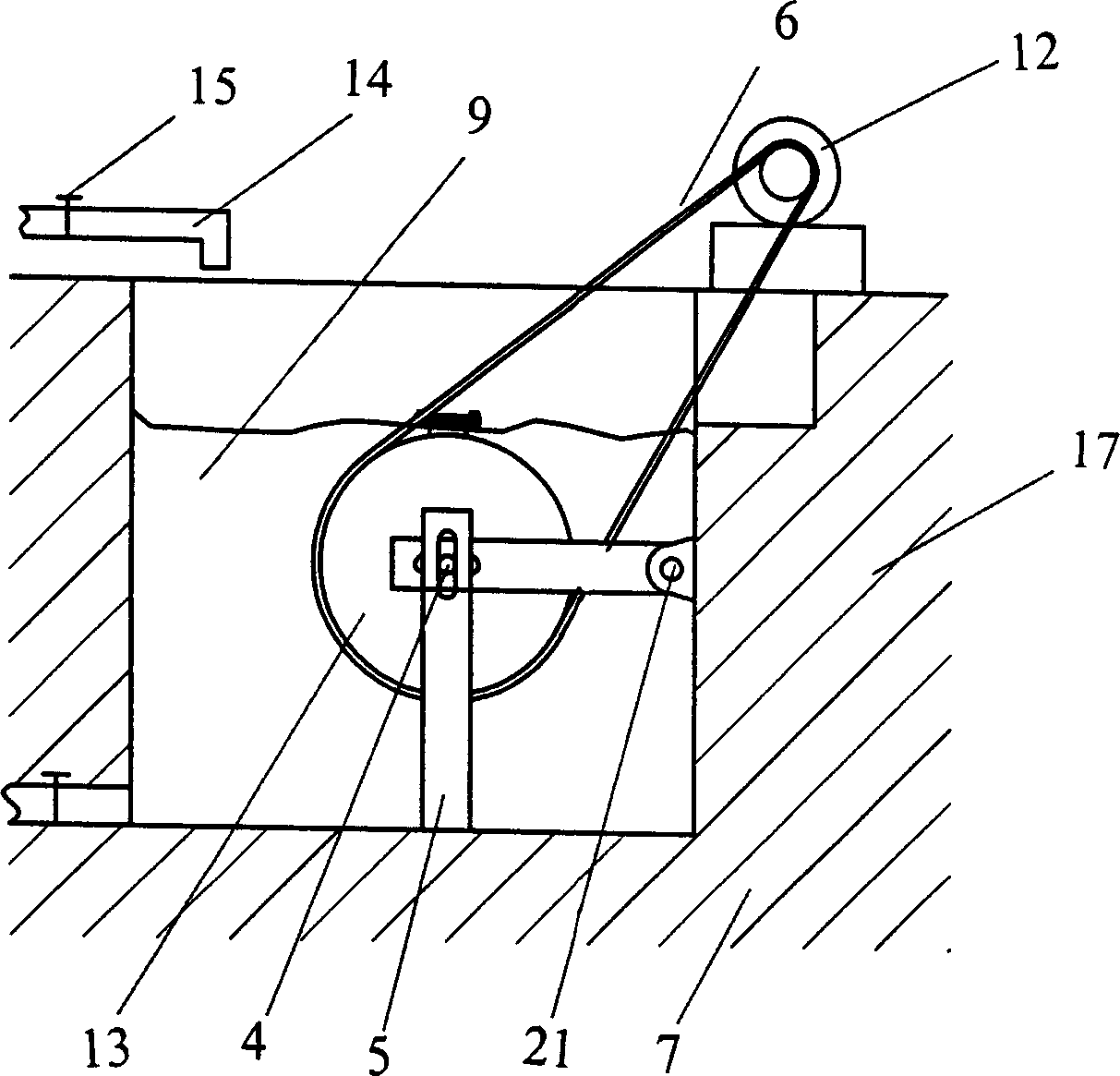

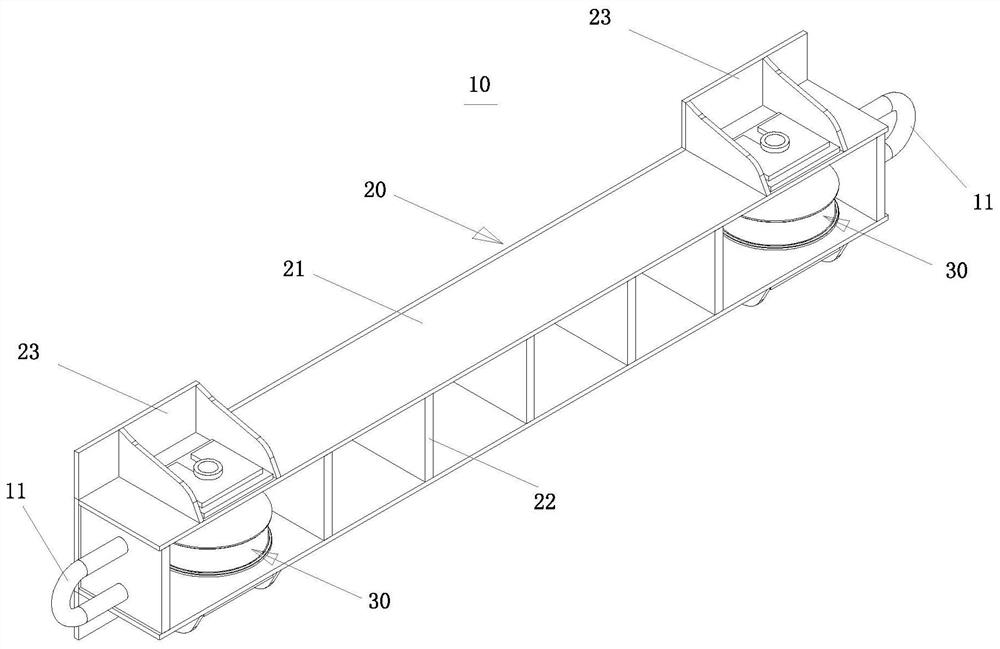

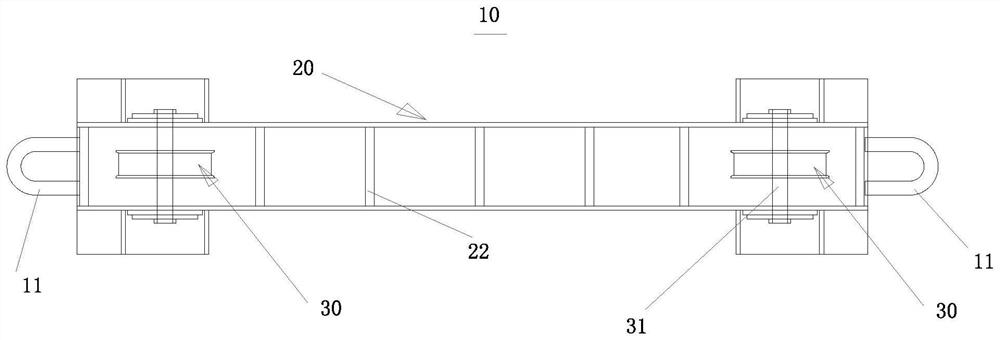

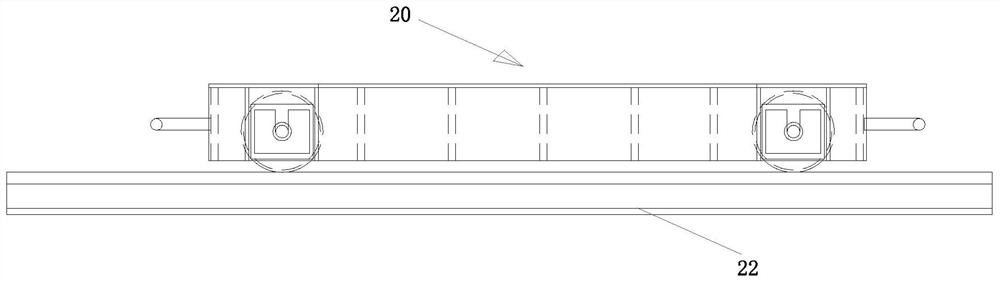

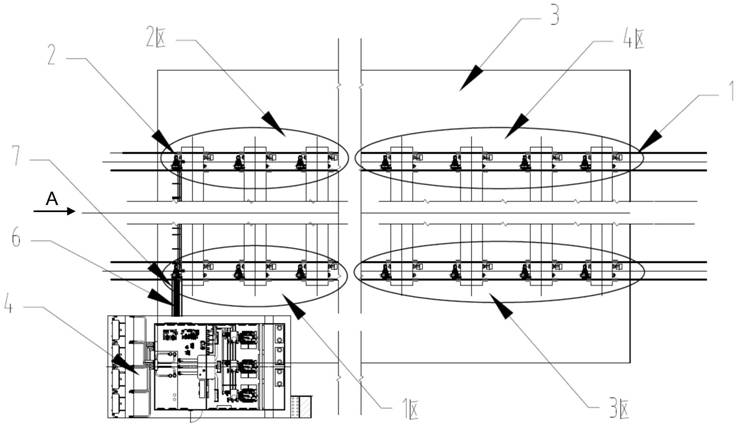

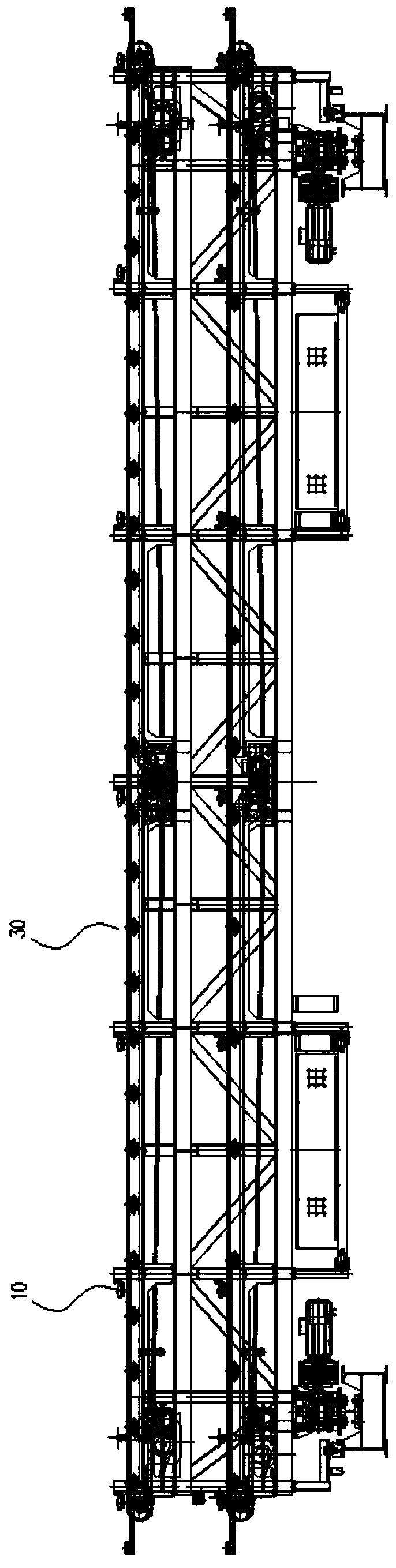

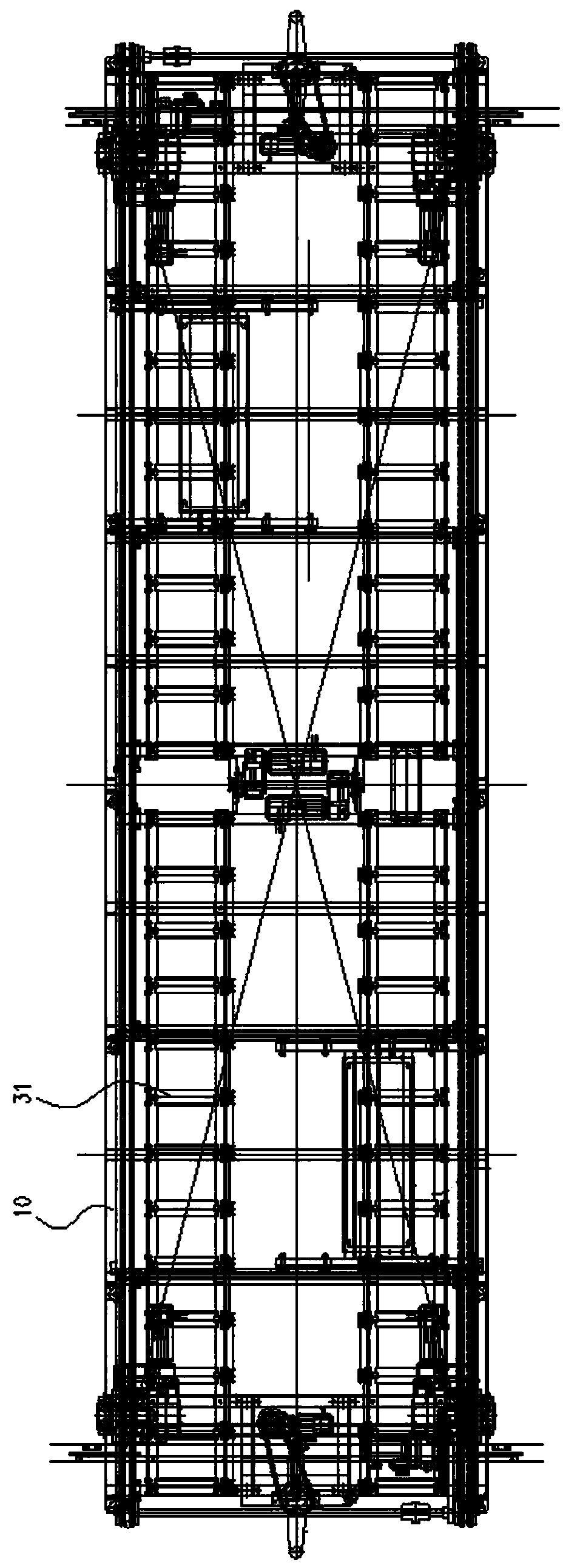

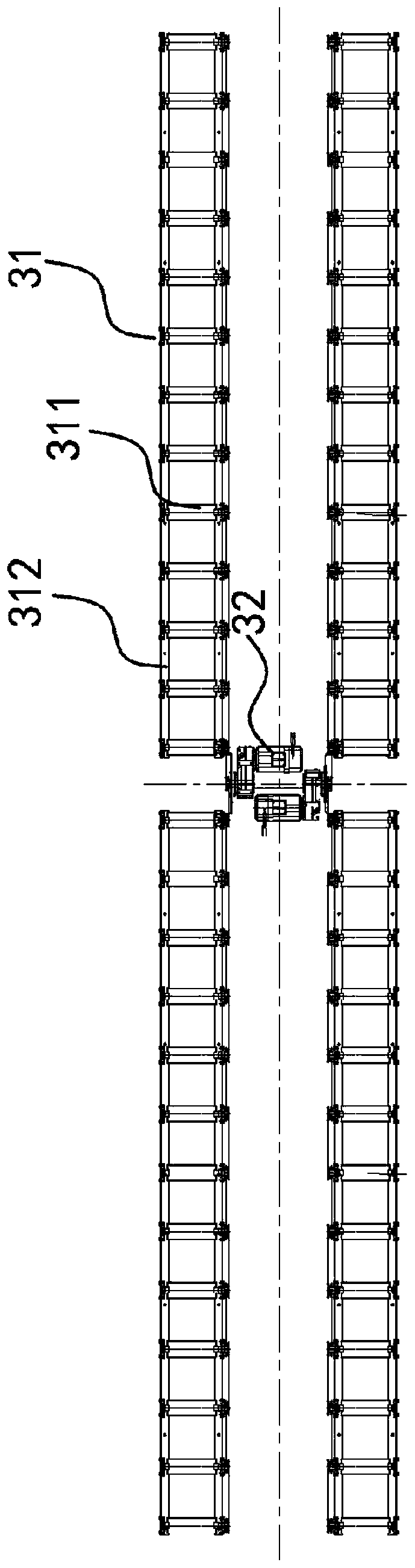

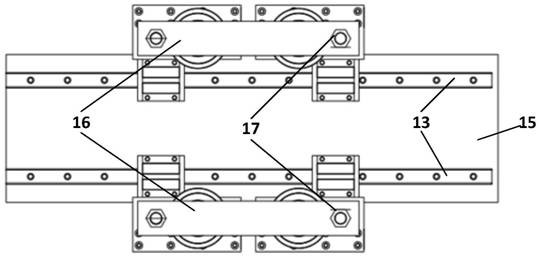

Jacking and sliding equipment special for blast furnace

InactiveCN112408288AImprove efficiencyAchieve vertical movementLifting devicesHoisting equipmentsStructural engineeringMechanical engineering

The invention provides jacking and sliding equipment special for a blast furnace. The equipment comprises a plurality of sliding grooves, sliding shoes, push-pull devices, transverse moving assembliesand jacking assemblies; wherein the plurality of sliding grooves are arranged side by side at intervals, the plurality of sliding shoes are arranged in each sliding groove, and the sliding shoes arearranged in the sliding grooves in a sliding mode; at least one sides of the sliding shoes in the sliding grooves are provided with the push-and-pull devices, the push-and-pull devices are selectivelyclamped on the sliding grooves, and the push-and-pull devices are connected with the sliding grooves in a sliding mode; the sliding shoes are provided with the plurality of transverse moving assemblies. and the sliding shoes are further provided with the jacking assemblies. According to the jacking and sliding equipment, the push-pull devices are selectively clamped on the sliding grooves, the sliding shoes are intermittently pushed to move in the longitudinal direction of the sliding grooves so that intermittent long-distance movement of the sliding shoes can be achieved; the transverse moving assemblies is used for supporting a blast furnace shell and driving the blast furnace shell to transversely move so as to adjust the transverse position of the blast furnace shell; and the blast furnace shell is jacked up through the jacking assembly so that the height position of the blast furnace shell can be adjusted.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

Hydraulic lifting travelling crane

The invention discloses a hydraulic lifting travelling crane. The hydraulic lifting travelling crane comprises a lifting cylinder and a travelling device, wherein the travelling device comprises a travelling crane frame and travelling wheels, the travelling crane frame is provided with a slide groove, the lifting cylinder is provided with an installation flange which is clamped in the slide groove and can move along the length direction of the slide groove, a horizontal cylinder is arranged at one side of the travelling device, the piston rod of the horizontal cylinder is hinged with the lifting cylinder, the horizontal cylinder and the lifting cylinder are connected with a manual reversing hydraulic system through pipelines, and when the manual reversing hydraulic system works, the lifting cylinder acts, the piston rod of the lifting cylinder stretches and withdraws so as to lift up or lay down heavy objects; the horizontal cylinder acts, the piston rod of the horizontal cylinder stretches and withdraws so as to push or pull the lifting cylinder, so that the lifting cylinder slides in the slide groove through the installation flange so as to horizontally reciprocate on the travelling crane frame. The lifting travelling crane can effectively prevent generation of electric spark, and is widely used in a coal mine, a gasoline station, a gas station and the like where combustible gas exists.

Owner:焦作市华科液压机械制造有限公司

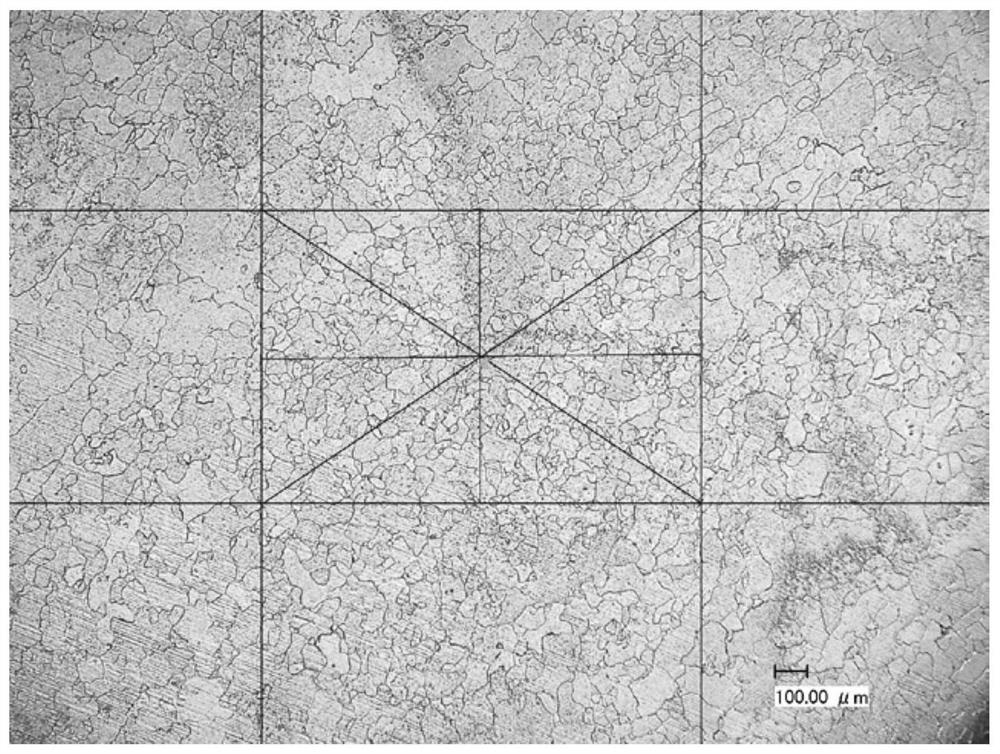

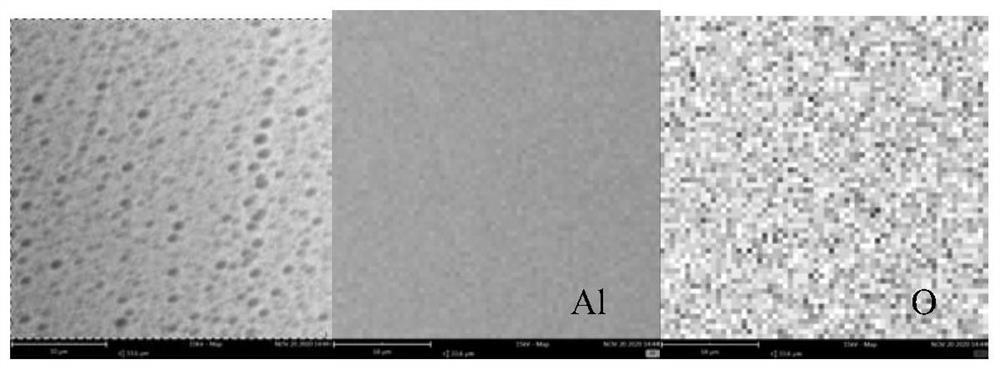

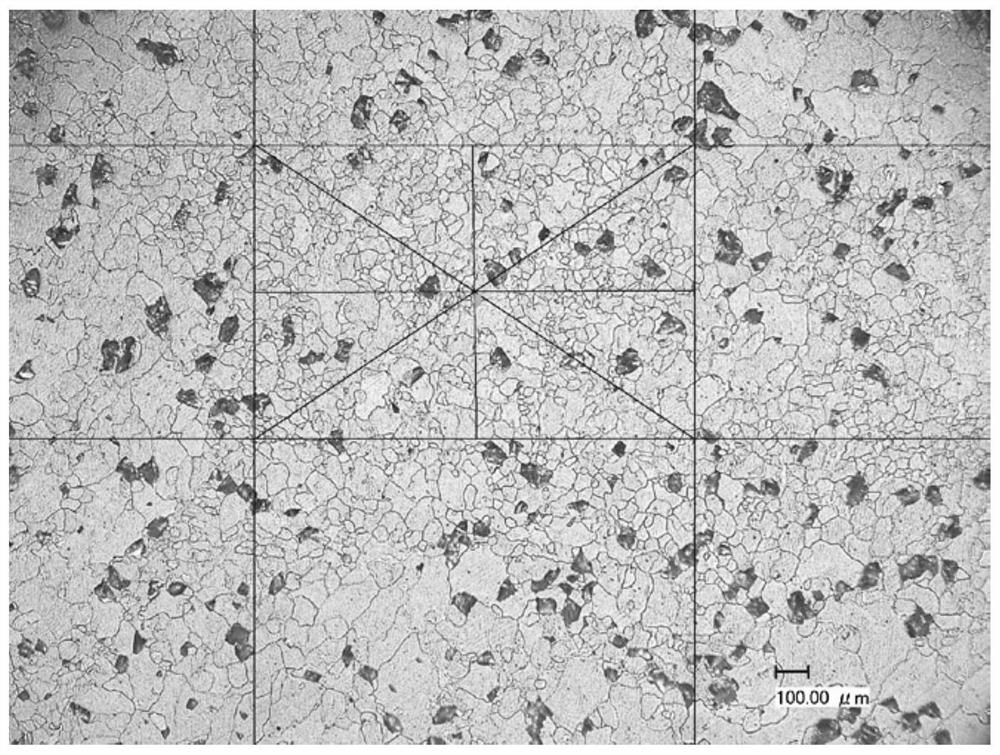

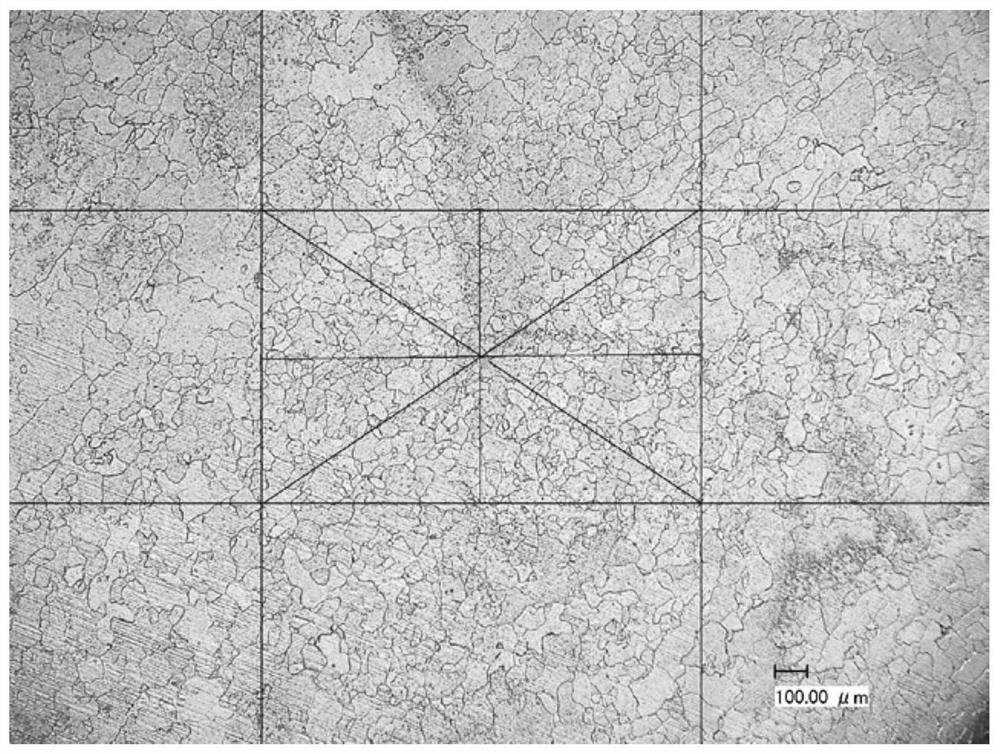

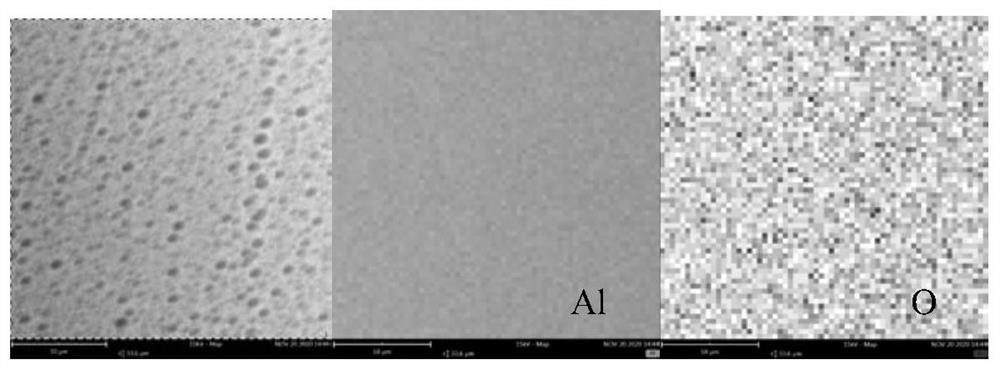

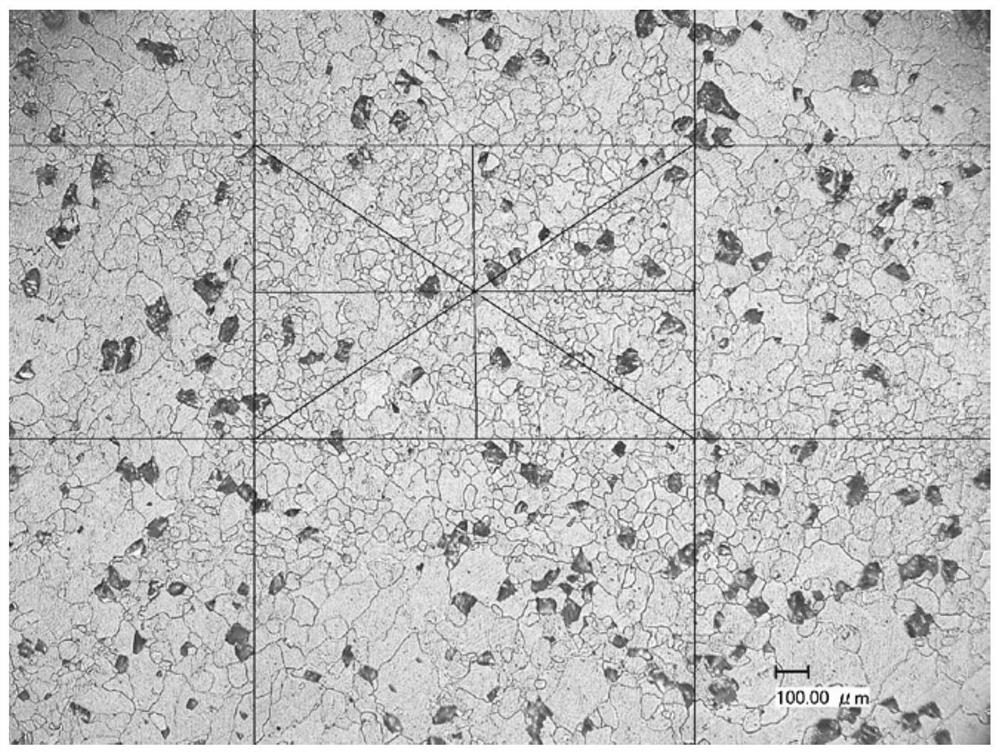

Method for manufacturing aluminum-silicon target material

ActiveCN112538598AGuaranteed mechanical propertiesGuaranteed film qualityVacuum evaporation coatingSputtering coatingIngot castingHeat conservation

The invention relates to a method for manufacturing an aluminum-silicon target material. The method comprises the following steps of: providing an AlSi ingot casting step, a drawing step, a primary upsetting step, an intermediate heat treatment step, a secondary upsetting step, a preheating treatment step, a calendaring step and an annealing heat treatment process step, wherein cold drawing operation is used in the drawing step, and a forging ratio X1 in the cold drawing operation is gerater than or equal to 1 and less than 2; in the primary upsetting step, a forging ratio X2 is greater than or equal to 2 and smaller than 3, and cold heading operation is used for primary upsetting; in the intermediate heat treatment step: a product is kept within a first preset temperature range, and is quickly put into cold water after being subjected to heat preservation for first preset time; in the secondary upsetting step, a forging ratio X3 is greater than or equal to 2 and smaller than 3, and cold heading operation is used for secondary upsetting; in the calendaring step: multi-pass calendaring is performed on the product, and reducing rolling reduction along with increase of calendaring passes; and in the annealing heat treatment process step: in an annealing temperature range, heat preservation is performed for third time, and water cooling treatment is performed to form a final targetproduct. According to the method, the forging ratio is reasonably controlled, water cooling is adopted for cooling, so that Si element precipitation is reduced, and therefore the microstructure and the machining performance of the target material are guaranteed.

Owner:爱发科电子材料(苏州)有限公司

Latticed anti-buckling supporting member provided with double T-shaped cores

InactiveCN103410239AIncrease the moment of inertiaIncreased bending stiffnessShock proofingFillet weldEngineering

A latticed anti-buckling supporting member provided with double T-shaped cores is formed by connecting two anti-buckling branches through a plurality of steel lattice plates respectively, wherein each anti-buckling branch supporting member adopts a T-shaped core member and a rectangular restrained concrete filled steel tube; long edges of the two branches are arranged in parallel at an appropriate interval, the latticed member is formed by connecting a plurality of longitudinally distributed steel lattice plates, the steel lattice plates are in welded connection with short edges of the branches through trihedral fillet welds, and the edge of the branches are the short edges of the rectangular restrained steel tubes. Ends of the two T-shaped core members extend out of the rectangular restrained steel tubes, and a ribbed plate is welded between outwards extending plates of the two cores, so that an H-shaped section is formed and can be connected with a frame member through a high-strength bolt and a connecting plate. The latticed section can increase the inertia moment of a whole section of the anti-buckling supporting member and the whole anti-bending stiffness and is particularly suitable for the design of a large-tonnage anti-buckling supporting member, a supporting end and the frame member are conveniently connected, and the energy-consuming capacity of the branches can be fully exerted under the action of an additional eccentric bending moment.

Owner:TSINGHUA UNIV

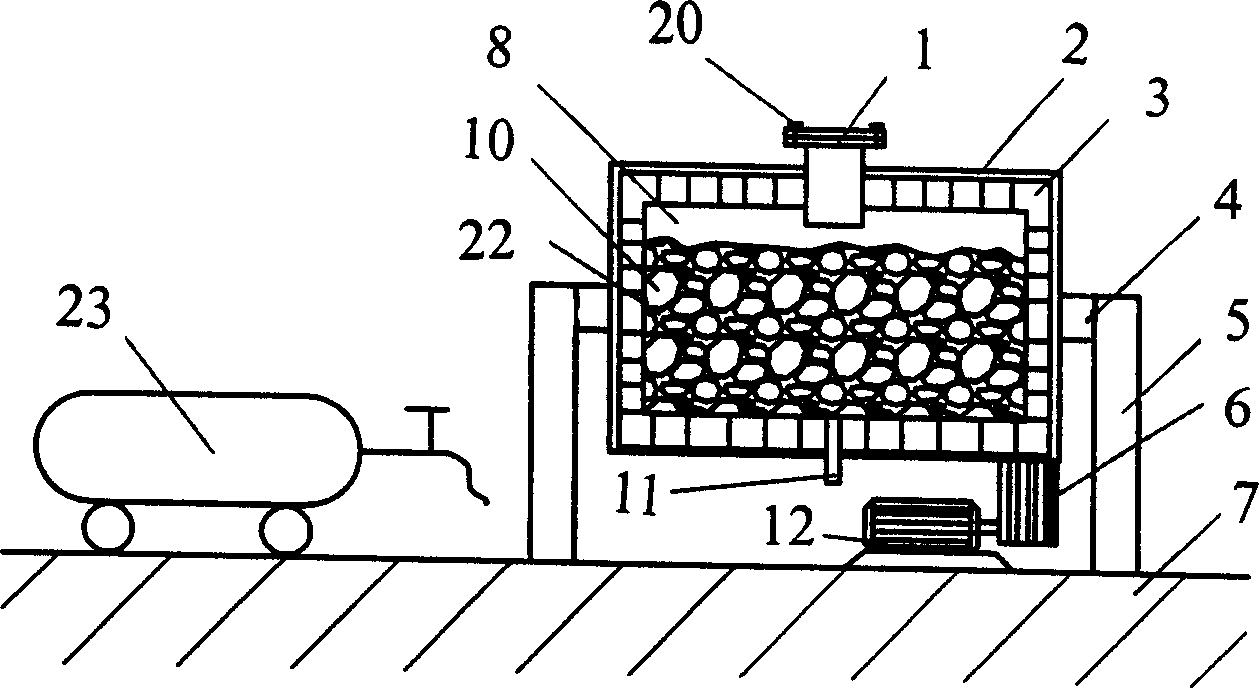

Liquid floated ball grinder

A floating-in-liquid ball grinding is composed of a material drum with material feeding and discharging openings and air inlet and outlet, driven system for driving said material drum, and open liquid pool containing liquid in which the part or all of material drum is floating. Its advantages are high grinding efficiency, low electric consumption and cost, and simple structure.

Owner:徐建

Vacuum magnetic suspension method for launching rocket in tunnel

The vacuum magnetic suspension tunnel rocket launching method has raised satellite launching safety coefficient and speed and can raise the rocket launching weight. The technological scheme of the present invention includes the following steps: excavating one smooth tunnel with special drilling machine in granite, establishing life saving and work stations along the tunnel, reinforcing the tunnel wall with glass fiber, installing Nd-Fe-B magnets or semiconductor superconductors, as well as linear motor coils, and fixing and filling with GRP to form smooth inner tunnel wall. The polarity of the magnets is the same as that in the rocket launcher.

Owner:陈秋平

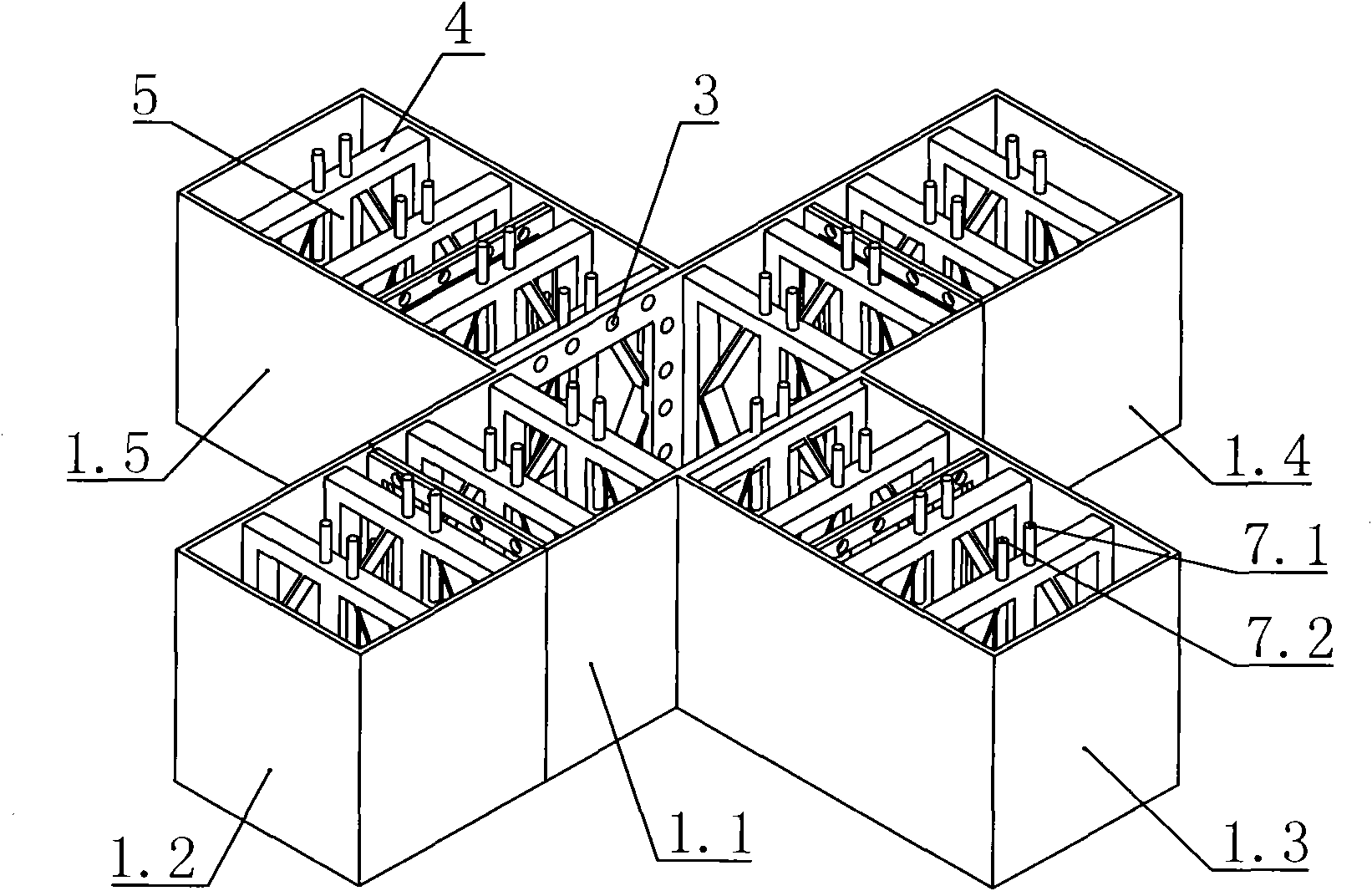

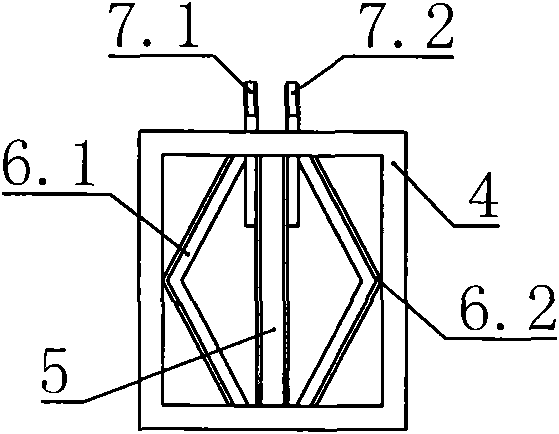

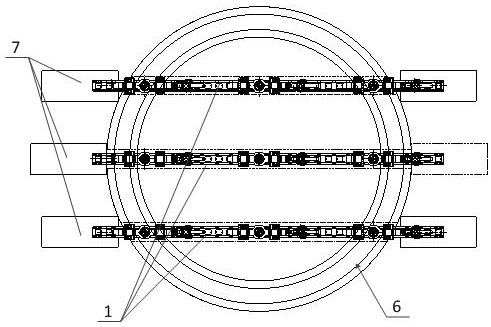

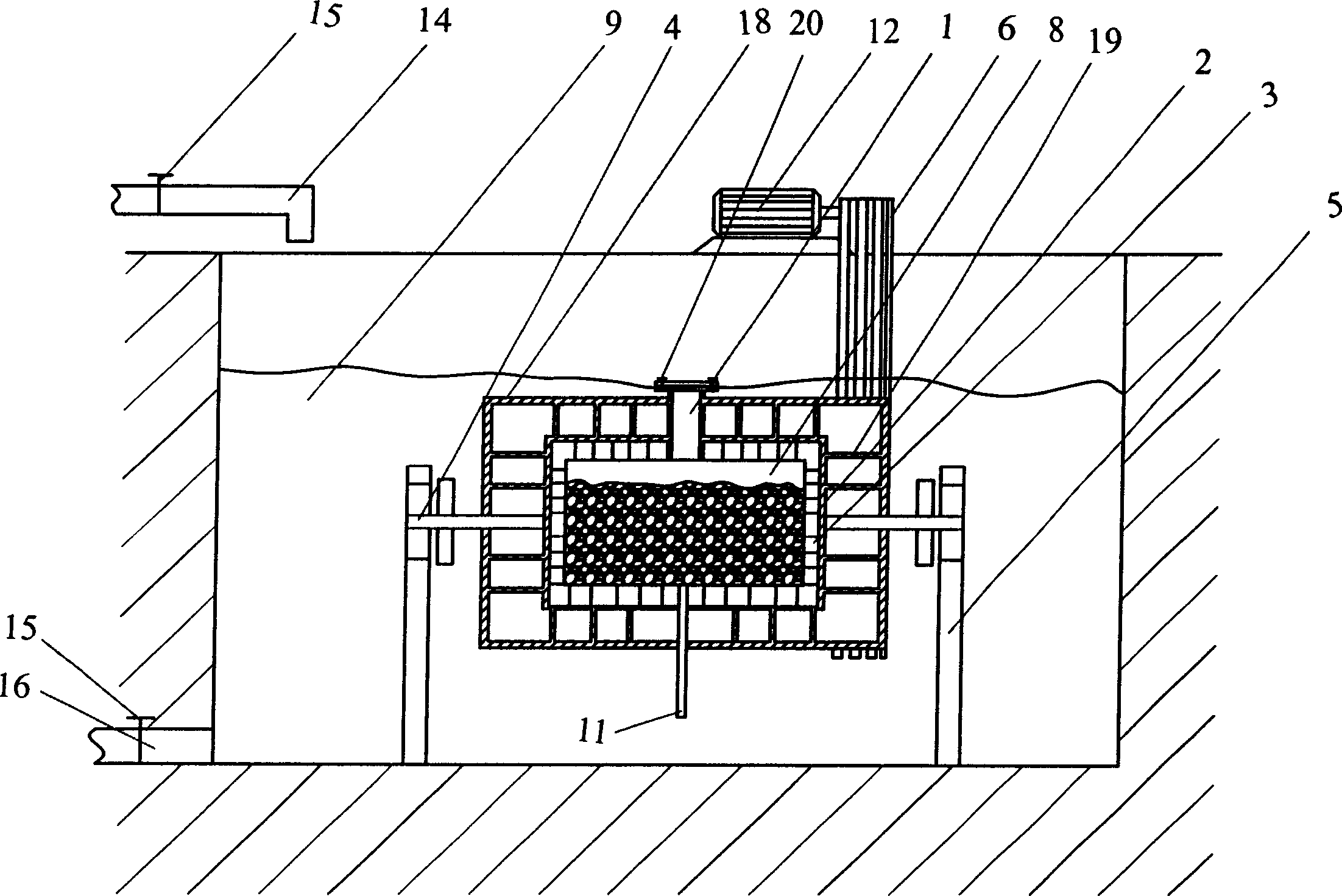

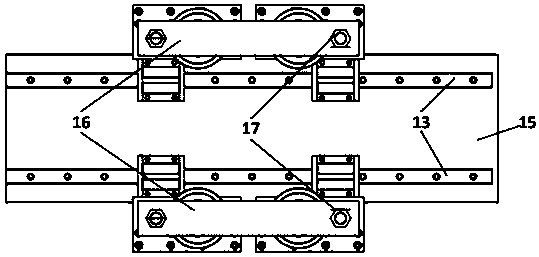

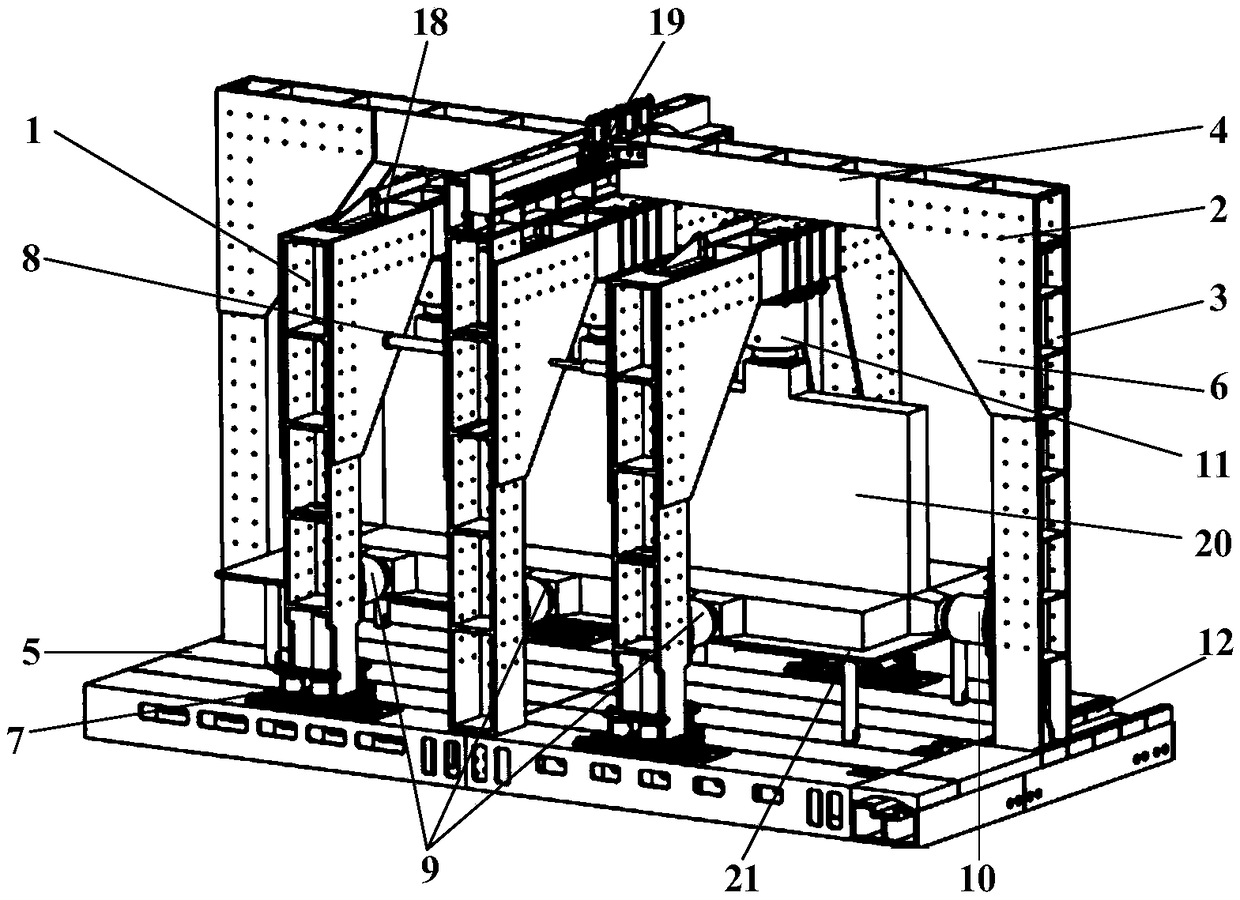

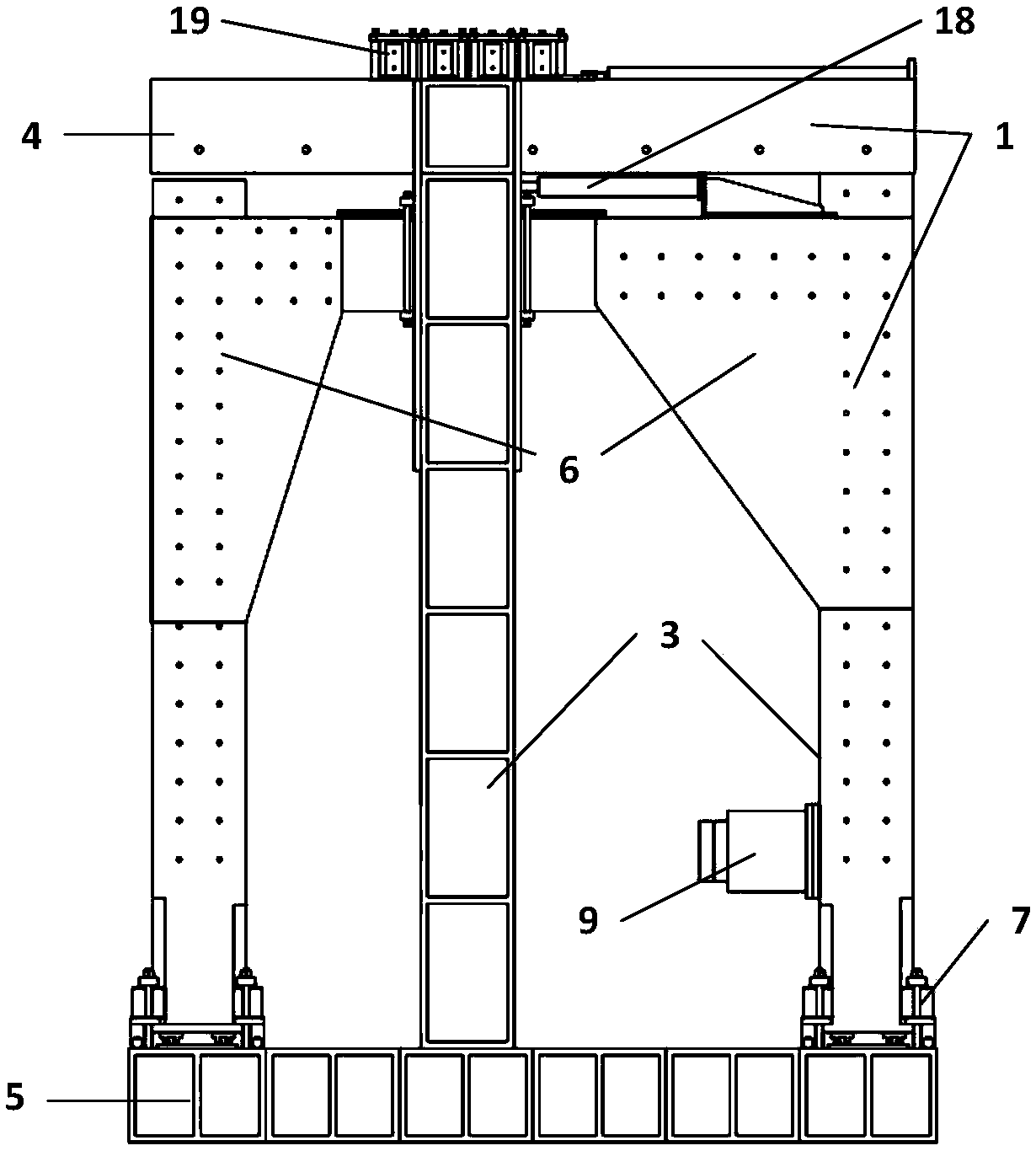

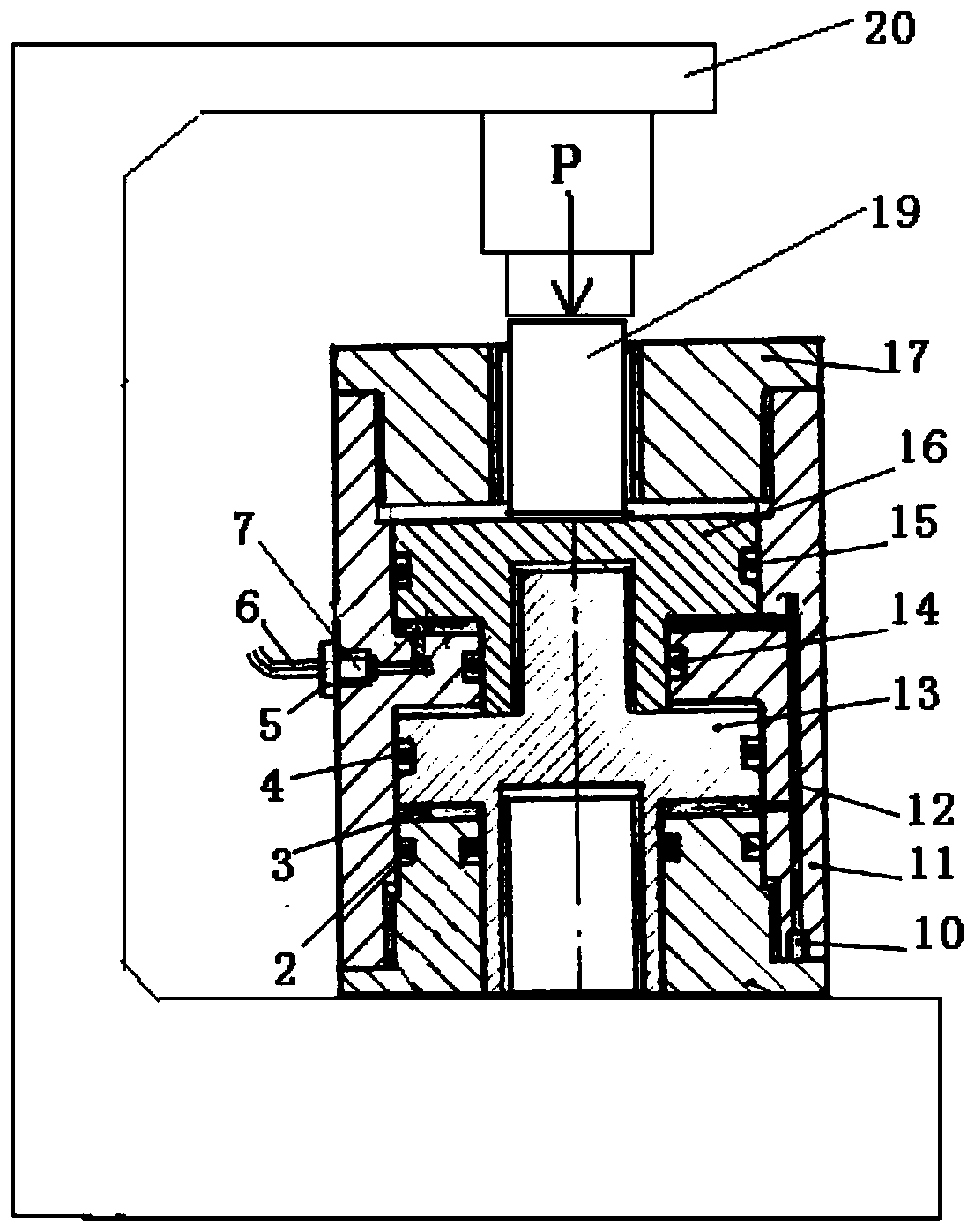

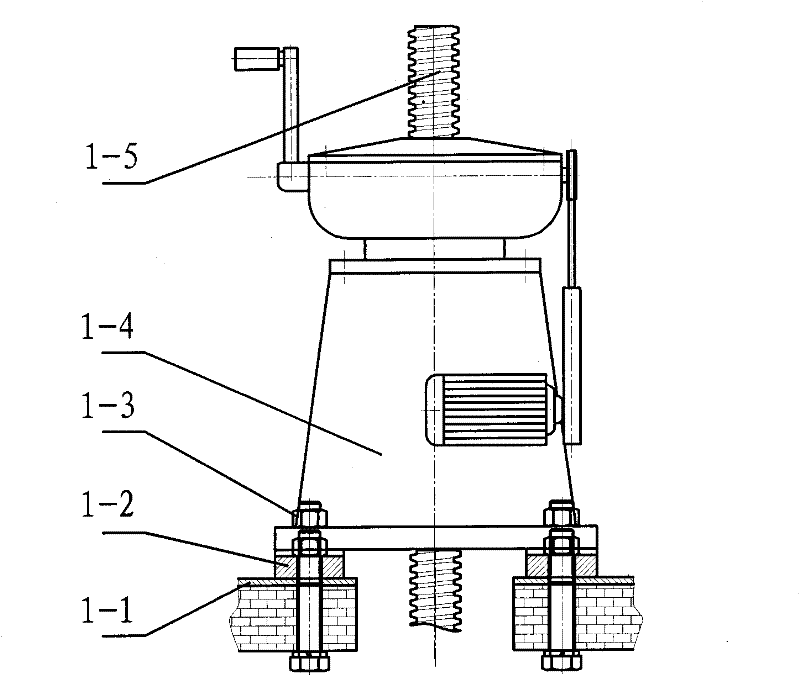

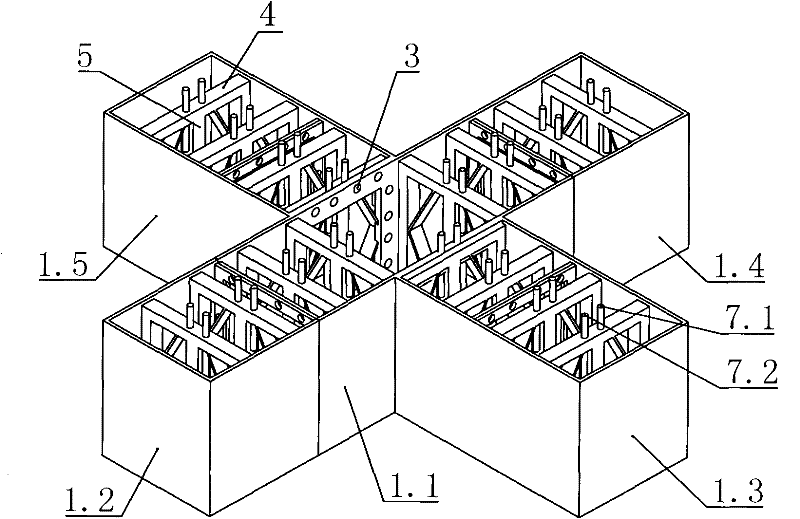

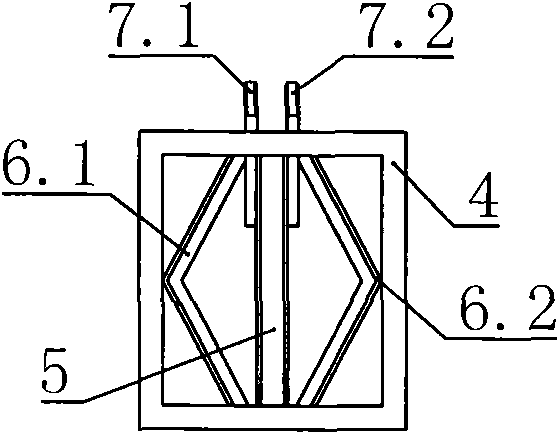

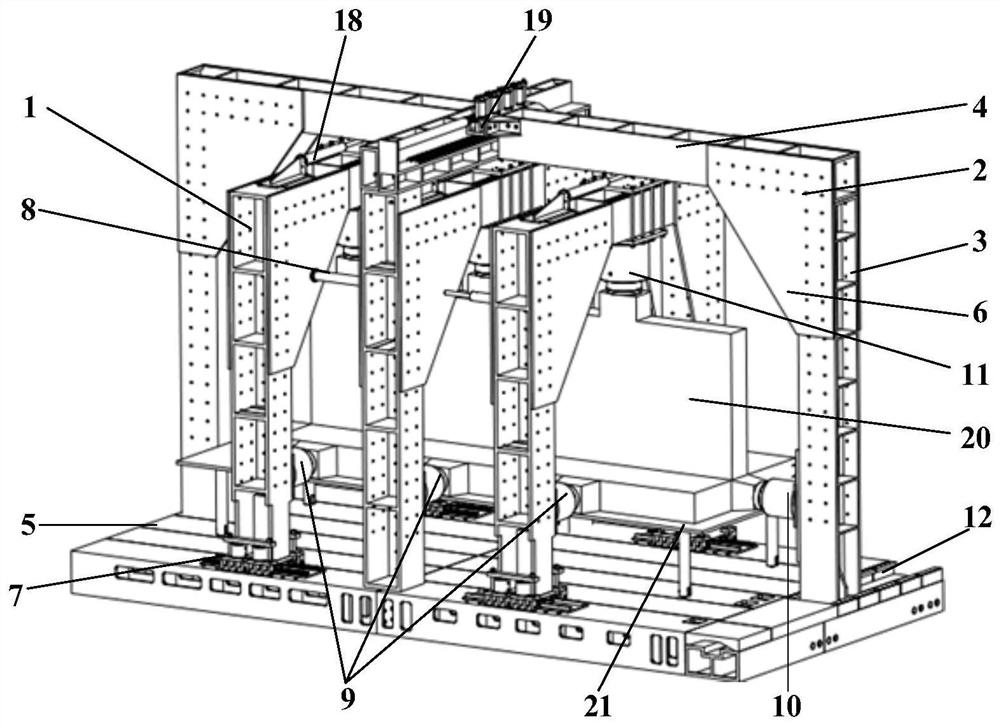

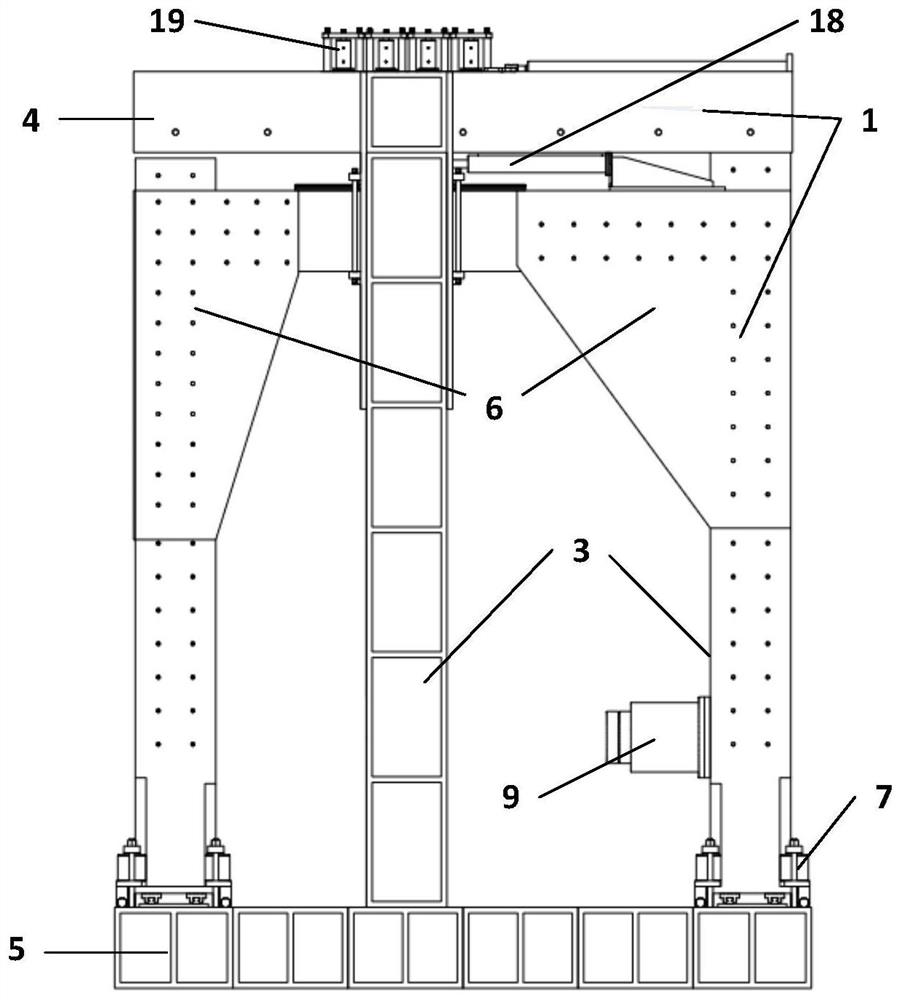

Adjustable three-dimensional loading test system suitable for steel concrete components with different sizes and shapes

ActiveCN109283058AMeet the requirements of three-dimensional loading testVersatileMaterial strength using tensile/compressive forcesSquare ShapeEngineering

The invention relates to a combined adjustable three-dimensional loading test system suitable for steel concrete components with different sizes and shapes. The combined adjustable three-dimensional loading test system comprises an assembly type base. The assembly type base is provided with a concentric-square-shaped structure I which can move in the left-right direction of the assembly type base,three concentric-square-shaped structures II are arranged inside the concentric-square-shaped structure I, the concentric-square-shaped structure II located in the middle is fixed, and the concentric-square-shaped structures II located on the two sides are driven by pushing cylinders to move in the front-rear direction of the assembly type base. A space enclosed by the three concentric-square-shaped structures II is internally provided with a lifting test platform, and the concentric-square-shaped structure I is provided with a rear loading cylinder for loading the rear part of the steel concrete components, and the concentric-square-shaped structures II are provided with side part loading cylinders for loading the side parts of the steel concrete components and upper part loading cylinders for loading the tops of the steel concrete components; and the loading cylinders are pushed and fixed by pushing and fixing devices.

Owner:SHANDONG UNIV

Method special for transporting heavy prefabricated arch bridge assembled box girder

InactiveCN111824191AAvoid damageLarge tonnageTramway railsRope railwaysArchitectural engineeringEconomic benefits

The invention provides a method for transporting a heavy prefabricated arch bridge assembled box girder in a remote area. The method comprises the following steps of a, providing two heavy low-gravity-center transport vehicles; b, building two steel rails extending from a starting place to a destination in parallel; c, synchronously installing two transport vehicles on the two steel rails; d, installing a winch on the fixed base at the destination, and connecting a steel wire rope to the two transport vehicles; e, placing the prefabricated arch bridge assembled box girder on the two transportvehicles through a jack; and f, starting the winch, using the steel wire rope to pull the two transport vehicles to synchronously move on the two steel rails, and transporting the prefabricated arch bridge assembled box girder to the destination. By using the method, manufacturing cost is low, installation is easy, and a transportation tonnage is large. The method is suitable for construction in remote areas, little in environmental damage, high in practicability, obvious in economic benefit and the like. Detaching is easy after a component is used.

Owner:SINOHYDRO BUREAU 12 CO LTD

Double-chamber hydragass spring

ActiveCN102121508BImprove sealingEasy maintenanceSpringsGas and liquid based dampersElastic componentEngineering

The invention relates to a double-chamber hydragass spring which comprises an upper lug, a lower lug, a main cylinder, an elastic component, a back pressure cylinder, a piston, a guide pipe and the like, wherein the upper lug is positioned at the upper part of the main cylinder; the lower lug is positioned at the lower part of the back pressure cylinder, the upper lug and the main cylinder are connected through a thread structure, and the lower lug and the back pressure cylinder are connected through a thread structure; the upper lug and the lower lug are both provided with a bearing internally; the side part of the upper lug is connected with the elastic component; and the piston and the guide pipe are installed in the back pressure cylinder. The double-chamber hydragass spring is characterized in that the back pressure cylinder, the piston and the guide pipe are connected into a whole and installed in the cylinder body of the main cylinder; a main cavity is formed by a space among the upper surface of the piston, the main cylinder and the space below the upper lug; a main air chamber is formed by the main cavity, an elastic component oil liquid chamber of the elastic component and an air chamber; a back pressure air chamber is formed by a back pressure chamber in the back pressure cylinder and a ring chamber positioned between the main cylinder and the back pressure cylinder; the back pressure chamber and the ring chamber are connected through a connecting pipe. The double-chamber hydragass spring has the beneficial effects of simple structure, small size, light weight, good tightness and large bearing tonnage and is convenient to arrange and install.

Owner:中国航天三江集团公司特种车辆技术中心

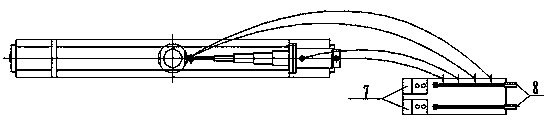

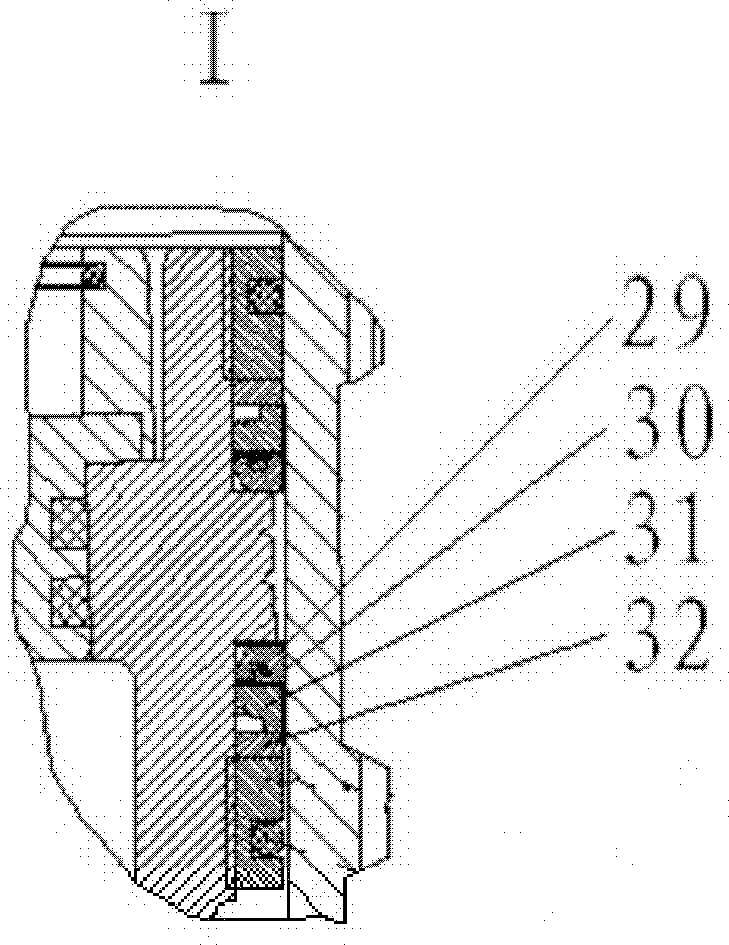

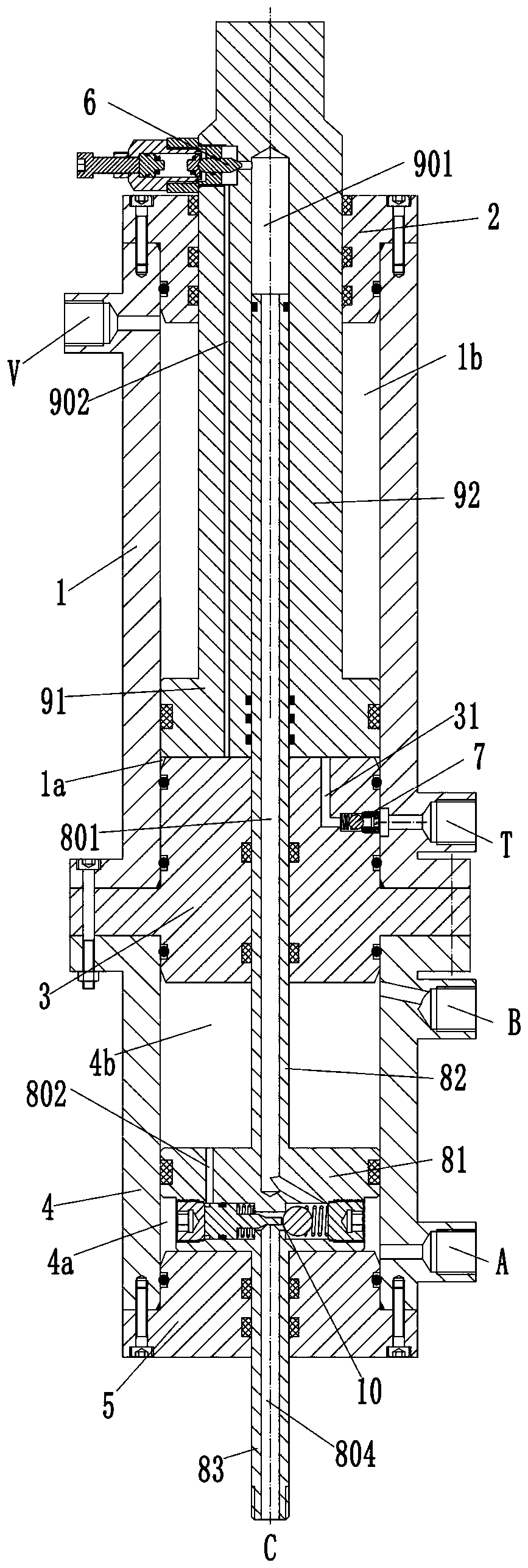

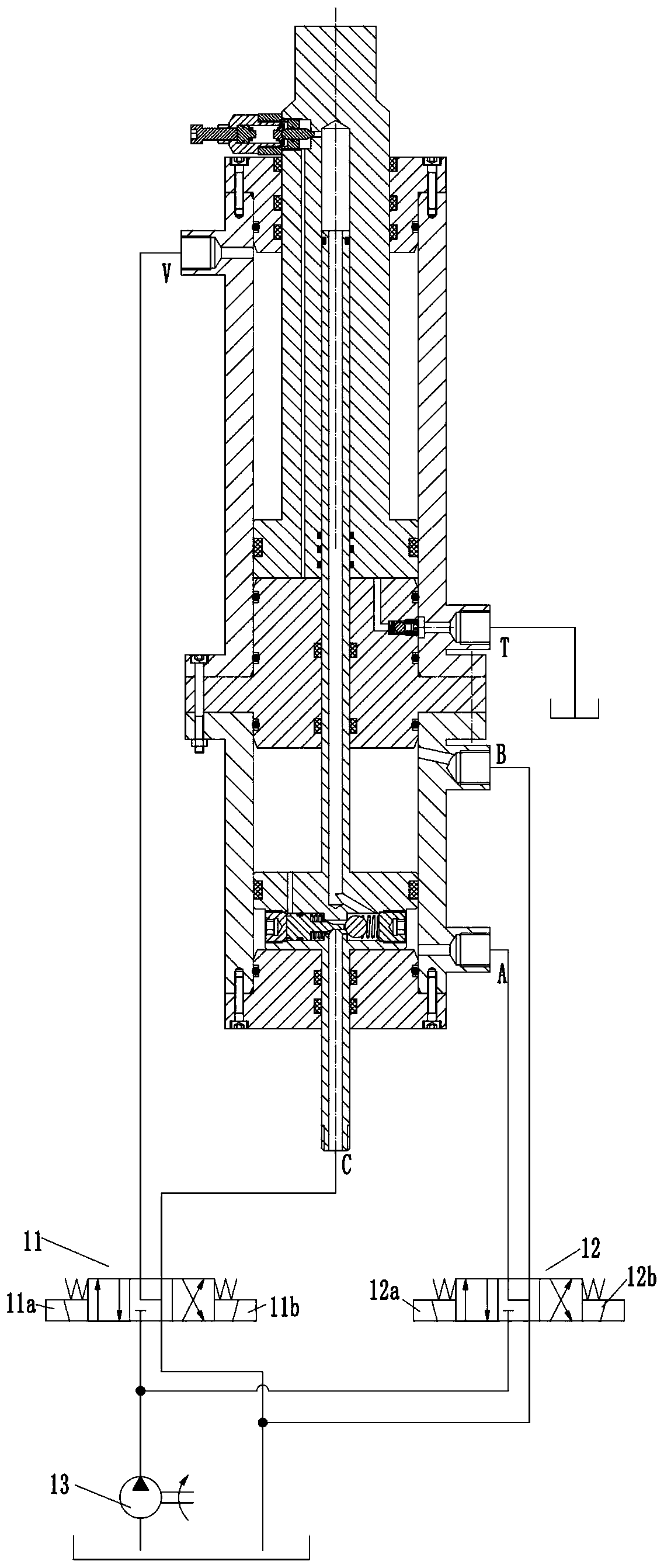

Quick oil cylinder with supercharging function

ActiveCN110454460ALarge outputLarge tonnageFluid-pressure convertersFluid-pressure actuatorsEngineeringCylinder block

The invention relates to a quick oil cylinder with a supercharging function. The quick oil cylinder comprises an upper cylinder body, an upper cylinder cover, a connecting block, an upper piston body,a two-way sequence valve, a lower cylinder body, a lower cylinder cover and a lower piston body, wherein a first oil port and a second oil port are formed in the upper cylinder body; the two-way sequence valve is arranged in the upper piston body; a third oil port and a fourth oil port are formed in the lower cylinder body; and the lower piston body comprises a first guide rod, a lower piston anda second guide rod, a fourth flow channel with a downward opening is formed in the second guide rod, and the lower opening of the fourth flow channel forms a fifth oil port. The quick oil cylinder has the advantages of the simple structure and compact size, and the quick extension and the supercharging function can be realized.

Owner:扬州市江都永恒气动液压有限公司

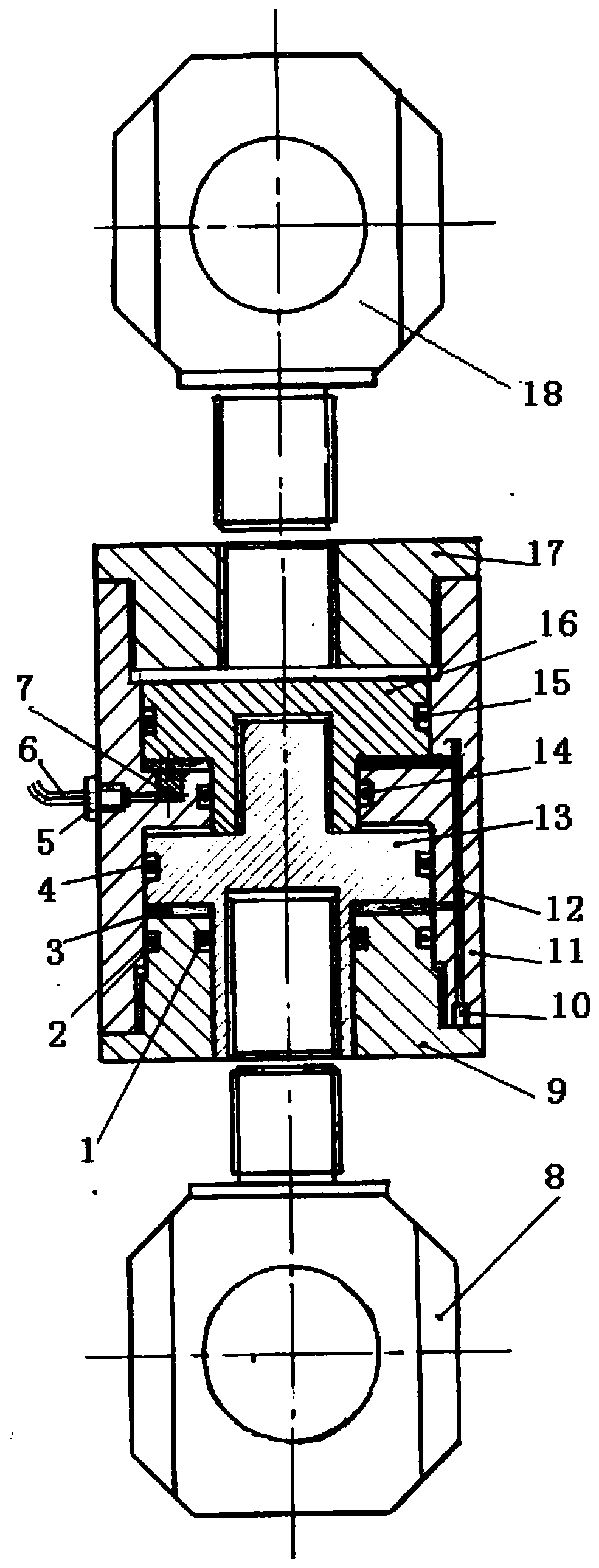

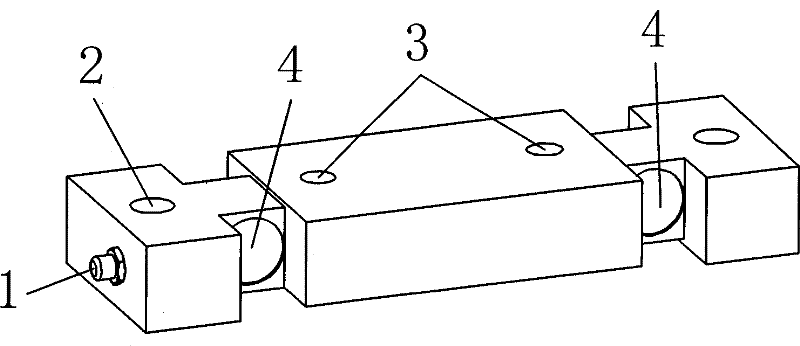

Double-layer piston type tensile and compression tensionmeter

PendingCN110375893ASolve the problem that the clamping difficulty cannot be calibratedSmall diameterForce/torque/work measurement apparatus calibration/testingHydraulic/pneumatic force measurementData acquisitionEngineering

The invention discloses a double-layer piston type tensile and compression tensionmeter which is composed of a cylinder body, a piston, grease, a top cover and a fluid pressure sensor. The tensionmeter is characterized in that the cylinder is composed of a cylinder and a cylinder bottom member; the cylinder body is internally provided with an interval which forms cylinder cavities communicated with each other up and down; the T-shaped piston is of an upper-lower connecting structure; the cylinder is provided with a sealed oil duct so that upper and down annular pressure cavities are communicated with each other; a protruded portion and top cover of the lower piston are provided with central threaded holes respectively, and can be connected with upper pulling force rings in a threaded way via the central threaded holes, thus, serve as the tensionmeter; the fluid pressure sensor generates an electric signal and sends the electric signal to a data collector via a signal line, and a pulling force value is calculated; and after that a movable bearing cylinder is mounted in the central threaded hole of the top cover, the tensionmeter can be directly mounted between a pressure object anda pressed object to measure the pressure value.

Owner:SHANDONG UNIV OF SCI & TECH

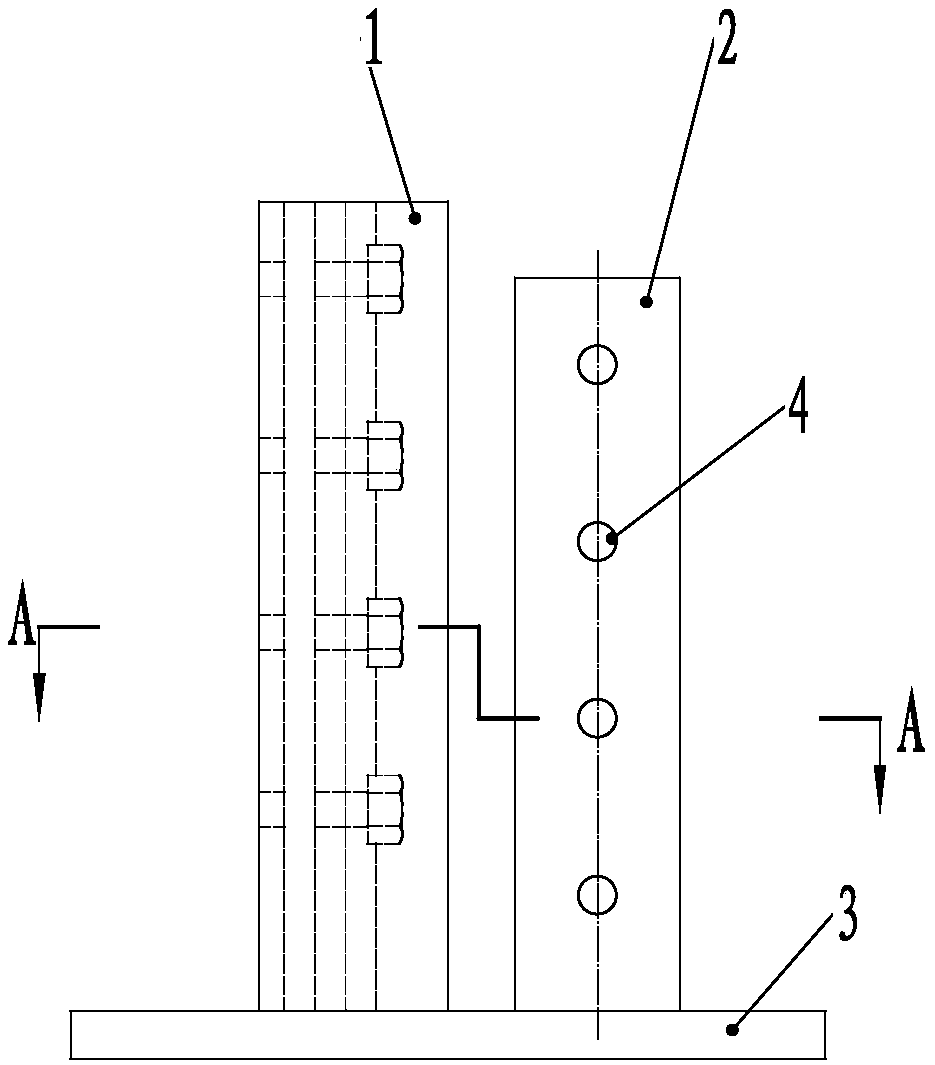

Base of a three-dimensional shelf

PendingCN109157076ACan't shakeReduce gapShow shelvesShow hangersPulp and paper industryWelding deformation

The invention discloses a base of a stereoscopic shelf. The base comprises a bottom plate, wherein, a U-shaped positioning column is arranged on the bottom plate, and a plurality of front connecting holes arranged longitudinally are arranged on the bottom surface of the U-shaped groove of the U-shaped positioning column. The bottom plate is also provided with a nut connecting plate, the nut connecting plate is located at the middle part of the U-shaped groove of the U-shaped positioning column, the nut connecting plate is provided with a nut plate connecting hole corresponding to the front connecting hole, and the hole end face of the nut plate connecting hole is provided with a fixing nut. The bottom plate is also provided with a tubular column, and a plurality of corresponding side connection holes are arranged on the two sides of the tubular column. The shelf assembled with the base has the advantages of large bearing tonnage, convenient installation and easy adjustment, ensures theaccuracy of the first layer of the shelf, reduces the welding deformation of the direct welding between the long column and the base, and improves the appearance of the shelf.

Owner:SHAANXI FL COLD FORMED STEEL CO LTD

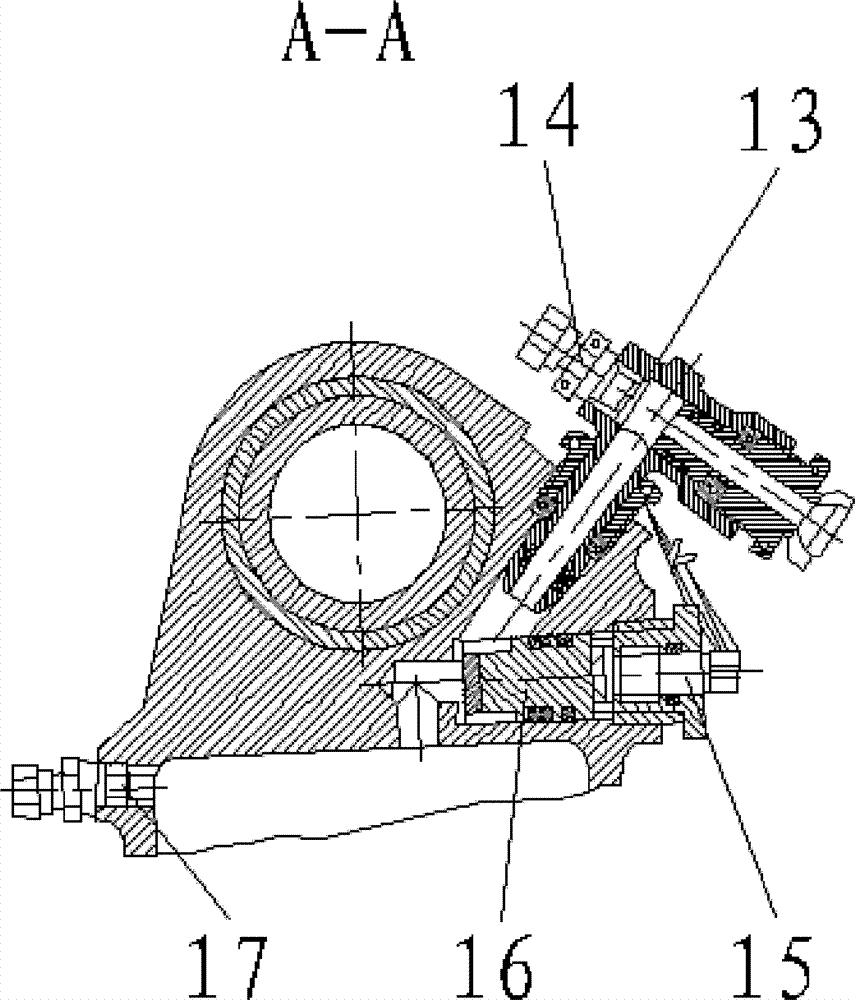

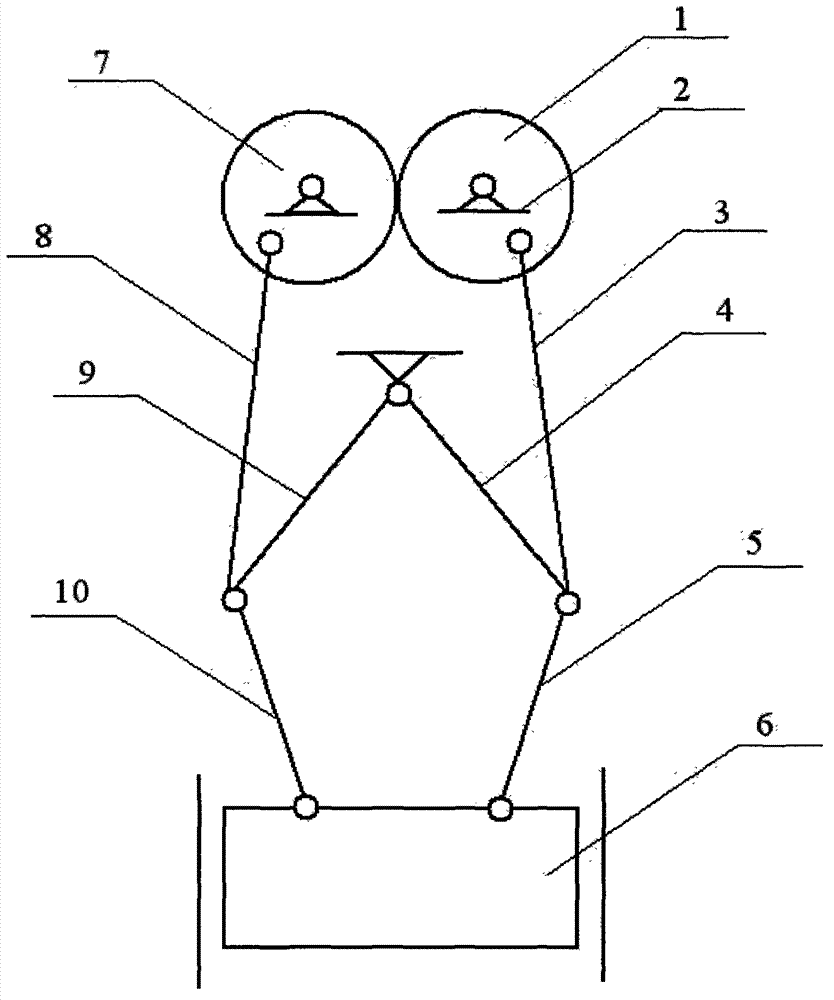

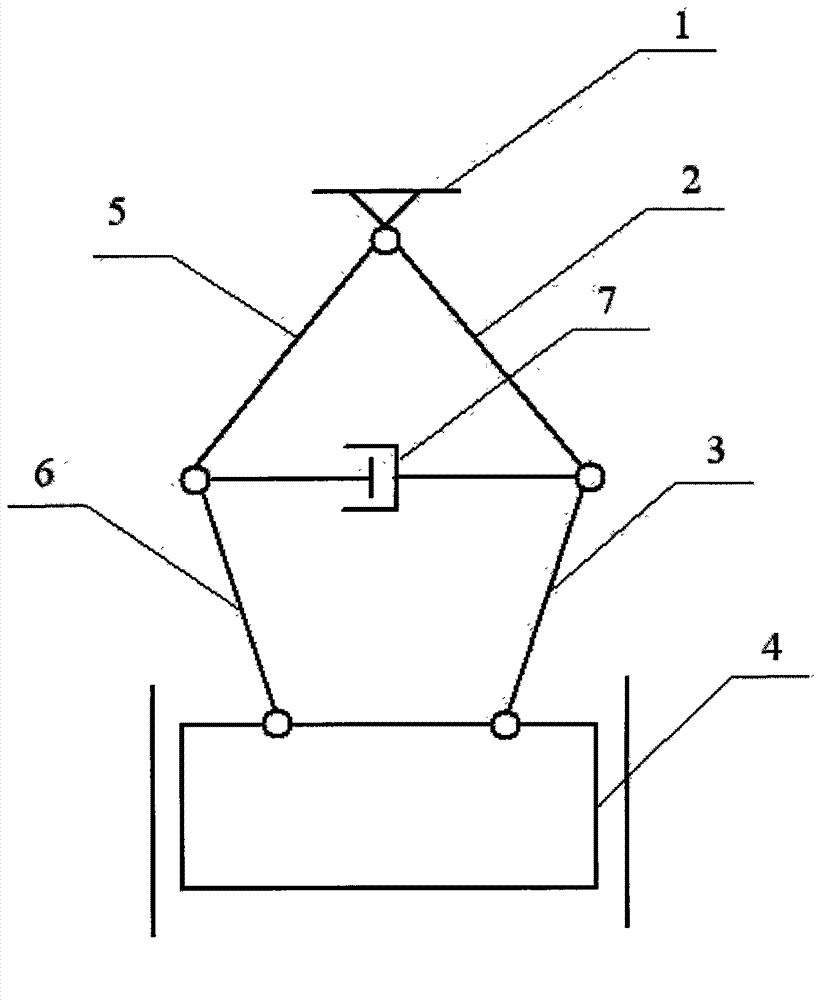

Duplex toggle link mechanical press

The invention relates to a duplex toggle link mechanical press. The press comprises a frame, two eccentric gears with the same teeth and mode number, two sets of left and right toggle link mechanisms consisting of two identical connecting rod branched chains, and a punch hammer, wherein the frame is connected with the punch hammer through the two sets of identical left and right toggle link mechanisms; the left and right toggle link mechanisms are symmetrically distributed on two sides of the frame; the eccentric gears in the left and right toggle link mechanisms are engaged with each other; the eccentric gear of each set of toggle link mechanism is connected with the frame through a revolute pair; the eccentric gears are connected with connecting rods through the revolute pair; the connecting rod, an upper toggle link and a lower toggle link are connected to the same part through the revolute pair; the upper toggle link is connected with the frame through the revolute pair; the lower toggle link is connected with the punch hammer through the revolute pair; and the punch hammer is positioned in a fixed guide rail and is connected with the frame through a sliding pair. The two sets of identical toggle link mechanisms are simultaneously driven by a high-power fixed rotating speed motor, so that the punch hammer has the operating characteristics of high efficiency, large tonnage and flexibility.

Owner:SHANDONG UNIV OF SCI & TECH

Manufacturing method of aluminum silicon target

ActiveCN112538598BGuaranteed mechanical propertiesGuaranteed film qualityVacuum evaporation coatingSputtering coatingEngineeringHeat conservation

The invention relates to a method for manufacturing an aluminum-silicon target, which includes the steps of providing AlSi ingots, and the elongating step. The elongating step adopts a cold drawing operation, and the forging ratio in the cold drawing operation is 1≤X1<2; a thickening step , the forging ratio is controlled to be 2≤X2<3, and cold heading is used for one pier; in the intermediate heat treatment step, the product is kept within the first preset temperature range, and after the first preset time of heat preservation, it is quickly placed in cold water; In the second pier step, the forging ratio is controlled to be 2≤X3<3, and the second pier is also used for cold heading; the preheating treatment step; the rolling step, the product is rolled for multiple passes, and with the increase of the rolling pass , the reduction is reduced; the annealing heat treatment process step is within the annealing temperature range, holding the heat for a third time, and performing water cooling treatment to form the final target product. The present invention reduces the precipitation of Si element by rationally controlling the forging ratio and adopting water cooling as the cooling method, so as to ensure the microstructure and processing performance of the target material.

Owner:爱发科电子材料(苏州)有限公司

Overload protection device of screw open-close machine

InactiveCN101787684BResistance increases or decreasesWith overload protectionBarrages/weirsForce measurementProgrammable logic controllerStrain gauge

Owner:徐州淮海电子传感工程研究所

Detachable tower foundation

The invention belongs to the technical field of building equipment, and provides a detachable tower foundation. The main characteristics are that the tower foundation comprises a base seat and a beam; the base seat is a crossed channel steel base seat formed by a centre base seat and four side base seats connected with the four sides of the centre base seat; a support member is arranged in the base seat; a crossed steel beam in the same shape as the base seat is arranged on and fixedly connected with the base seat; and a tower-crane base seat is correspondingly arranged on the upper surface of the steel beam. Compared with the existing disposable tower foundation and the prior detachable power foundation, the invention has the advantages of easy mounting and detachment, convenient transportation, repeatable use, reduced building cost, and the like.

Owner:陈金生

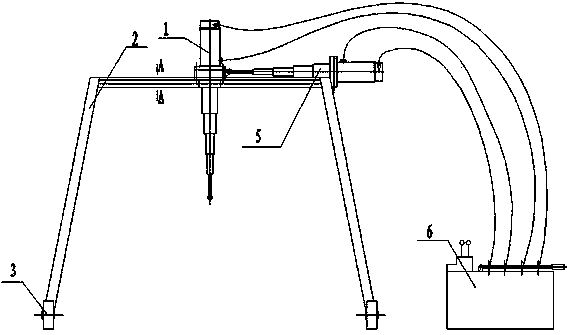

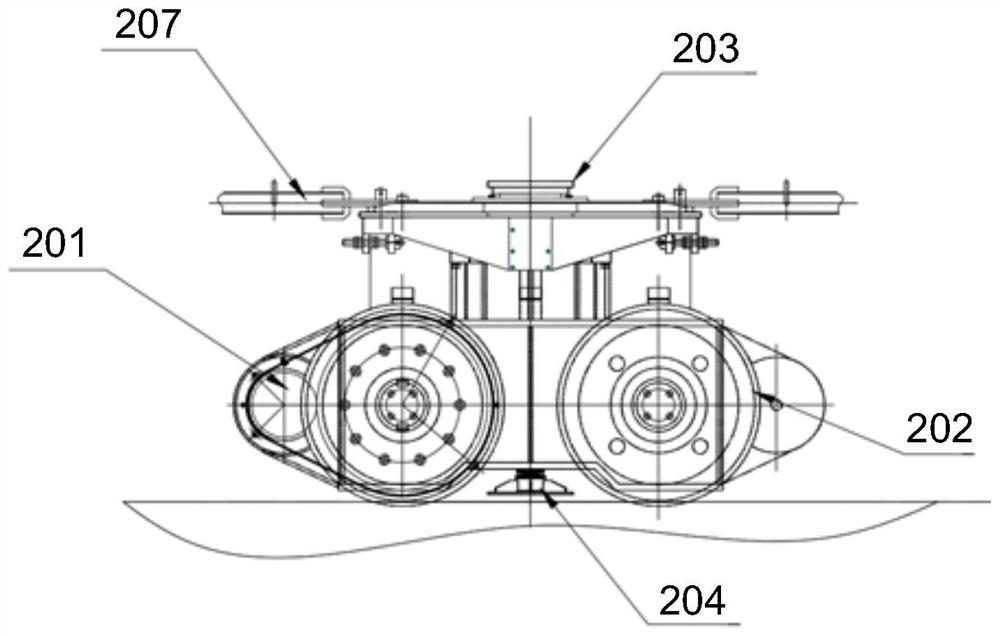

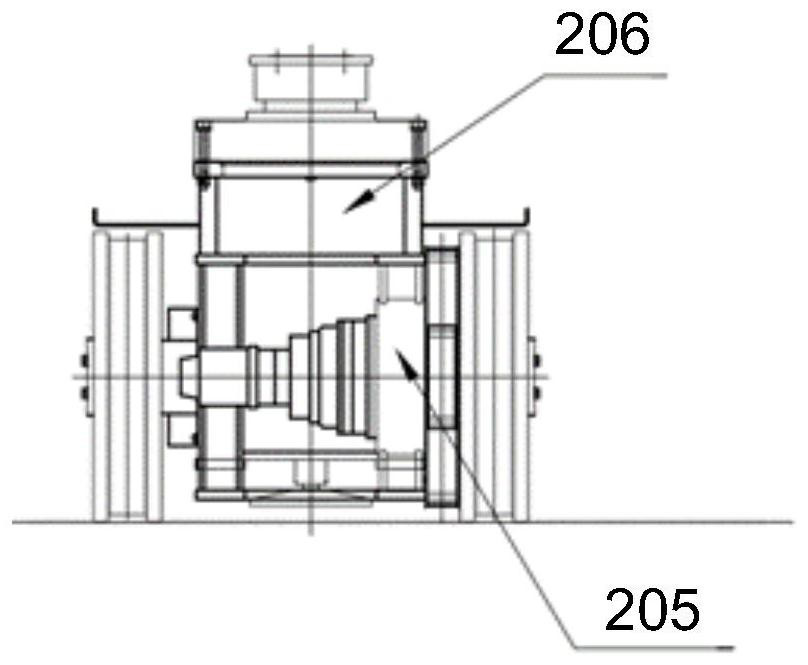

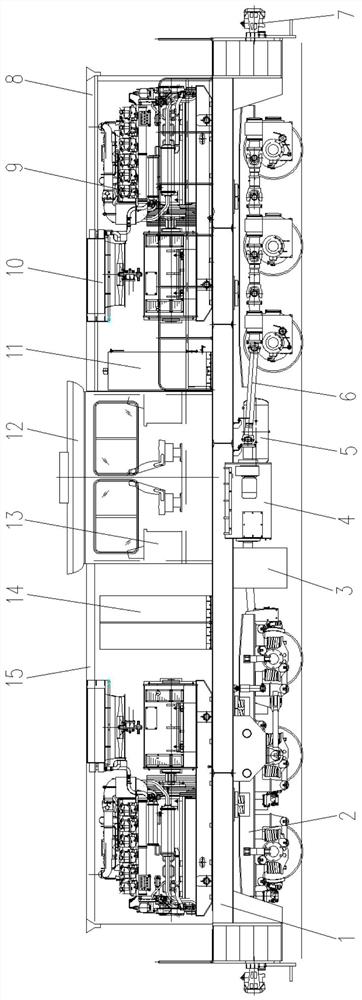

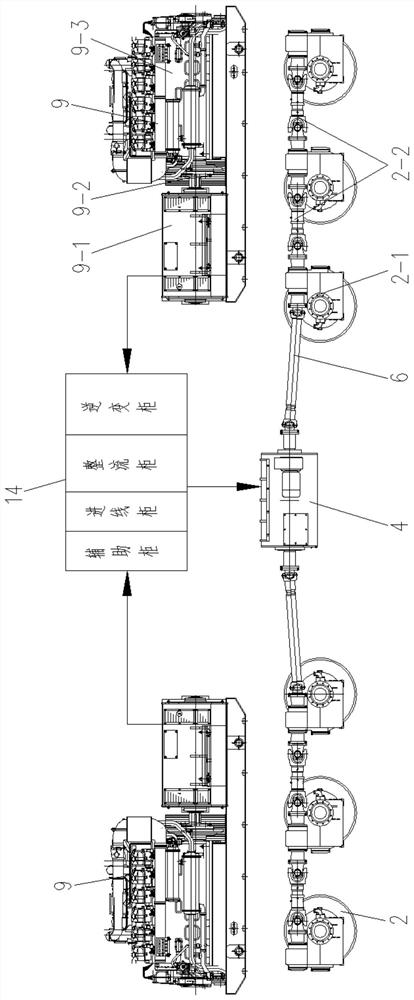

Transfer system and method for ships or large components

The invention discloses a transfer system for ships or large components, which comprises a walking guide rail laid on the ground of a site, multiple ship moving trolleys arranged on the walking guide rails and used for jacking and moving ships or large components, a power unit vehicle connected with the ship moving trolley and providing power for the ship moving trolley, and an operation table used for controlling the actions of the ship moving trolley and the power unit vehicle through a master control PLC. The invention discloses a transfer method based on the transfer system. The whole ship can be safely, reliably and conveniently transferred.

Owner:SHANGHAI ZHENHUA HEAVY IND

Hydraulic pressure machine

The invention relates to a hydraulic pressure machine, comprising a rack, an upper connecting rod of a right branch chain, a lower connecting rod of the right branch chain, a punching hammer, an upper connecting rod of a left branch chain, a lower connecting rod of the left branch chain and a hydraulic cylinder, wherein the rack is connected with the punching hammer by the left branch chain and the right branch chain which are same; the right branch chain is formed by the upper connecting rod and the lower connecting rod which are connected by a rotating pair; the left branch chain is formed by the upper connecting rod and the lower connecting rod which are connected by a rotating pair; the upper connecting rod and the lower connecting rod of the right branch chain are respectively connected with the rack and the punching hammer by a rotating pair; the upper connecting rod and the lower connecting rod of the leftt branch chain are respectively connected with the rack and the punching hammer by a rotating pair; one end of the hydraulic cylinder is connected with the upper connecting rod and the lower connecting rod of the right branch chain by a rotating pair at the same point, and the other end of the hydraulic cylinder is connected with the upper connecting rod and the lower connecting rod of the left branch chain by a rotating pair at the same point; and the punching hammer is fixed in a guide rail and is connected with the rack by a movable pair. The hydraulic pressure machine has the advantages that two sets of force increasing mechanisms are driven by utilizing the hydraulic cylinder, so that high-efficiency, large-tonnage and high-stability stamping operation can be obtained, and simultaneously the difficulty for controlling the synchronous and coordinated movement of the two branch chains can be avoided.

Owner:SHANDONG UNIV OF SCI & TECH

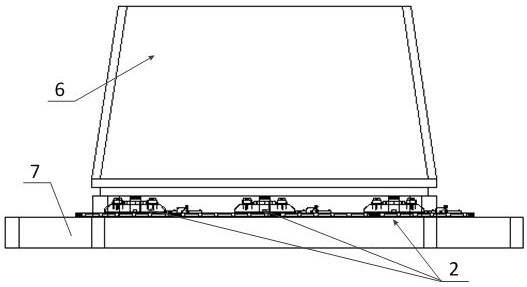

Garage car plate conveying device

A garage vehicle carrying plate conveying device is used for conveying a vehicle carrying plate bearing a vehicle and comprises a frame mechanism, a first conveying portion and a first conveying driving portion, wherein the first conveying portion and the first conveying driving portion are located on the frame mechanism, the first conveying portion comprises multiple rollers arranged in the conveying direction, and the rollers can rotate under the driving of the first conveying driving portion so as to convey the vehicle carrying plate. The garage vehicle carrying plate conveying device comprises the roller-type first conveying portion and has higher bearing capability. Compared with tooth comb-type exchange and clamping-type exchange, the garage vehicle carrying plate conveying device can effectively bear large-tonnage buses, accordingly achieves exchange and storage of large-tonnage buses having large parking sizes, accordingly is conductive to establishment of stereo bus parking garages, makes the buses not stopped on the sides of roads, can convey the buses to parking spaces of the stereo parking garage, and the problem is solved that an existing stereo parking garage cannot meet large bus standards.

Owner:中集物联科技有限公司 +3

Anti-buckling supporting member with lattice type three-circular-pipe cross section

An anti-buckling supporting member provided with a lattice type three-circular-pipe cross section comprises three anti-buckling branches which are connected through batten pieces of inclined batten pipes, transverse batten pipes and the like as well as end ribbed plates, wherein each anti-buckling branch adopts an anti-buckling supporting member provided with a linear core and a concrete-filled restraint circular steel pipe; the three anti-buckling branches have the same sizes, are parallelly arranged to form a regular-triangle cross section, and are connected through the transverse batten pipes and the inclined batten pipes to form a lattice type member; and the transverse batten pipes and the inclined batten pipes are connected with the constraint circular steel pipes of the anti-buckling branches through intersecting weld. End parts of the linear core members of the three anti-buckling branches extend out of the circumferential constraint circular steel pipes, a ribbed plate is vertically welded at the externally extending section of each core, and the three ribbed plates are interested to the center of the regular triangle and welded to be a whole, so that end nodes of the anti-buckling supporting member are formed. The lattice type cross section facilitates improvement of the bearing efficiency of the anti-buckling supporting member, can remarkably reduce the weight of the member, and meets the design requirement of large-tonnage and ultra-long anti-buckling support in structures of a giant frame and the like.

Owner:TSINGHUA UNIV

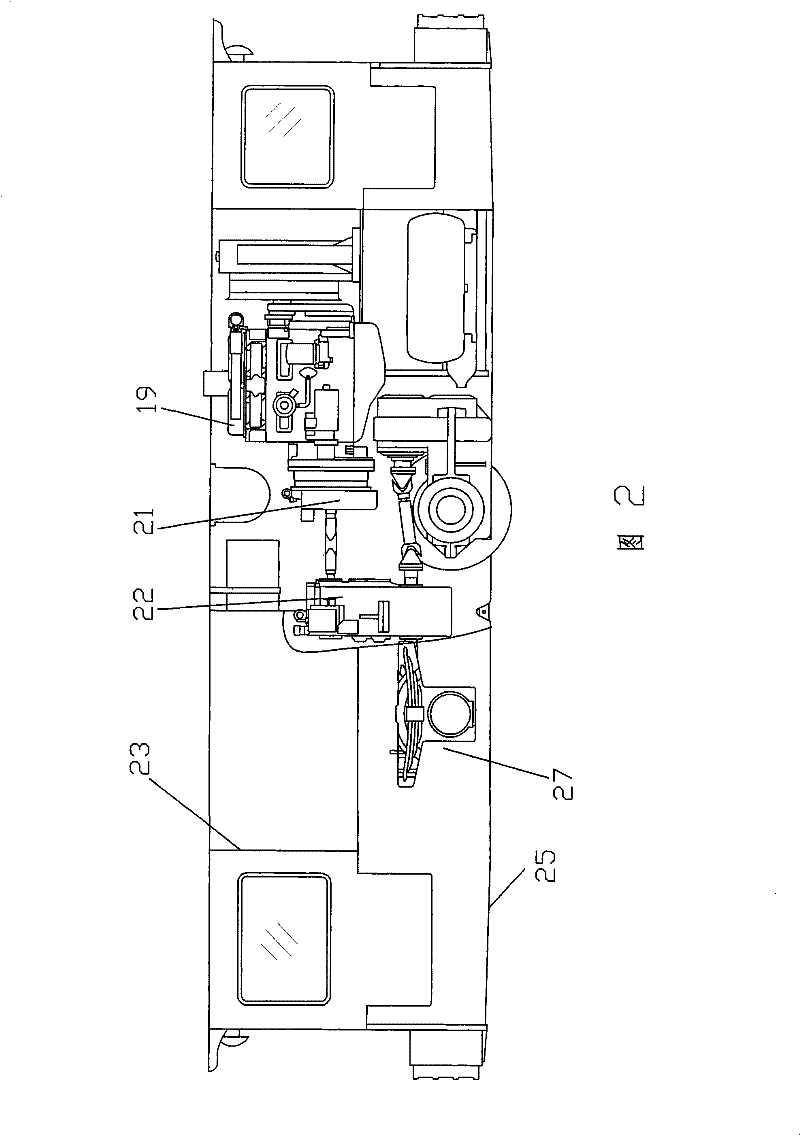

Hydraulic transmission type anti-explosion diesel engine steel wheel standard rail diesel locomotive

InactiveCN101434241BWill not useMeet actual needsIC reciprocating piston engine transmissionFluid gearingsVehicle frameDiesel locomotive

The invention relates to a hydraulic power explosion-proof diesel steel-wheel common-rail diesel locomotive, comprising an explosion-proof diesel, a hydraulic torque converter, a steering-shifting box, a main body, a frame, a traveling part and assistive devices; wherein, the explosion-proof diesel is provided with an output disk; the hydraulic torque converter comprises a pump wheel, a turbine, a guiding wheel, an output shaft, a base and a pump casing fixedly connected with the pump wheel; the turbine and the guiding wheel are both arranged in the pump casing; the pump wheel is fixedly connected with a pump wheel seat; the turbine is fixedly connected with the output shaft and the pump wheel seat is movably connected with the base; the guiding wheel is fixedly connected with the base; and the output disk is movably connected with the pump casing. The invention has the beneficial effects that the power of the diesel can be thoroughly performed and the working of the diesel under overload can be avoided and the locomotive can automatically change speed and driving force according to the road condition and resistance value to adapt to various conditions so as to realize infinitely variable speeds, high transmission efficiency, stable starting, large driving tonnage and better economic effect and to fully satisfy the requirement of users.

Owner:江苏华成工矿机车有限公司

Electric drive six-shaft rail tractor

PendingCN112622942AIncrease powerLarge adhesive weightElectric motor propulsion transmissionBogiesBogieVehicle frame

The invention provides an electric transmission six-shaft rail tractor which comprises a tractor frame, three-shaft bogies are arranged on the lower portions of the two ends of the tractor frame, a traction motor is arranged in the middle of the lower portion of the tractor frame, and the traction motor outputs from the two ends and is connected with the inputs of the three-shaft bogies through transmission shafts I to drive the three-shaft bogies to walk; a cab is arranged in the middle of the upper portion of the vehicle frame, a machine room I is arranged at one end of the upper portion of the vehicle frame, a machine room II is arranged at the other end of the upper portion of the vehicle frame, and diesel generator sets and heat dissipation devices are arranged in the machine room I and the machine room II respectively. A diesel tank is arranged in the machine room I. A rectifying device is arranged in the machine room II. The diesel tank is communicated with the diesel generator set to supply oil to the diesel generator set. Current generated by the diesel generator set is integrated through the rectifying device and then supplied to the traction motor. The invention relates to the electric transmission traction rail car, which adopts a traction motor for double-end output driving and a three-axle bogie for six-axle driving, has the characteristics of large adhesion traction force and low cost, and is suitable for goods transportation of industrial and mining enterprises and stations.

Owner:宝鸡中铁中联科技发展有限公司

Adjustable three-dimensional loading test system for reinforced concrete members of different sizes and shapes

ActiveCN109283058BMeet the requirements of three-dimensional loading testVersatileMaterial strength using tensile/compressive forcesClassical mechanicsStructural engineering

The invention relates to a combined adjustable three-dimensional loading test system applicable to steel concrete members of different sizes and shapes, comprising an assembled base, on which is provided a circular shape that can move along the left and right directions of the assembled base Structure I, there are three return-shaped structures II inside the return-shaped structure I, wherein the return-shaped structure II in the middle is fixed, and the return-shaped structures II on both sides can be assembled along the The type base moves forward and backward; a lifting test platform is arranged in the space surrounded by three back-shaped structures II, and a rear loading oil cylinder for loading the rear part of the reinforced concrete member is provided on the said back-shaped structure I. Said return-shaped structure II is provided with a side loading oil cylinder and an upper loading oil cylinder for loading the side and top of the reinforced concrete member; the loading oil cylinder is pushed and fixed by a moving fixing device.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com