Pre-stress spiral rib hollow grouting anchor rope

A technology of grouting anchor cables and spiral ribs, which is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc., can solve the problems of low support strength, resin solidification installation, and large elasticity of anchor cables, and achieve the construction steps Simplification, small installation hole, good straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

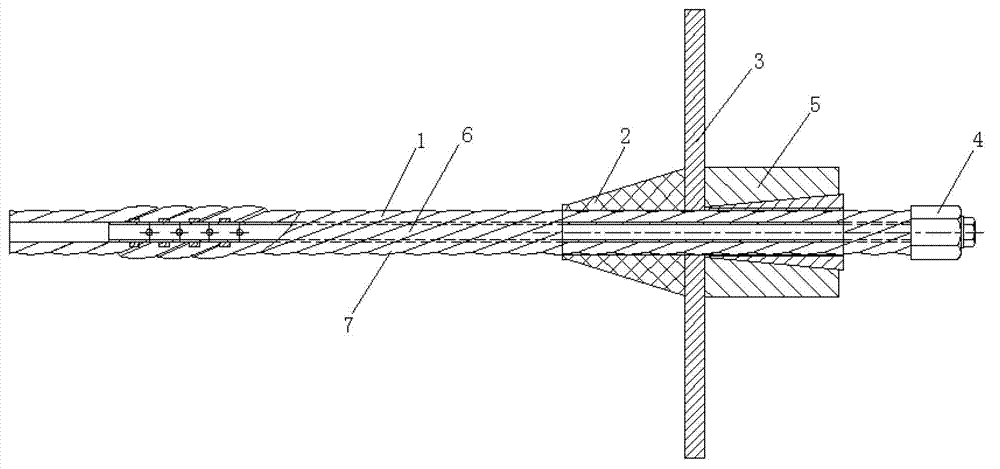

[0021] Referring to the accompanying drawings, the prestressed spiral rib hollow grouting anchor cable includes an anchor cable body 1 extending into the rock and soil borehole, and the anchor cable body 1 is braided by several high-strength spiral rib prestressed steel wires 7 3-6 continuous protruding spiral ribs are formed on the surface of the steel wire 7, the spiral ribs are integrated with the base circle of the steel wire, the rear end of the anchor cable body 1 is fixedly connected with the sling 5, the anchor cable body 1, the cable The tool 5 passes through the grouting core pipe 6, the rigging 5 is fitted with the tray 3, the rigging 5 at the rear end of the tray 3 is screwed with a lock nut 4, and the lock nut 4 presses against the rear end surface of the tray 3, The back end of the anchor cable body 1 is covered with a grout stopper 2 facing the rock and soil borehole, and the grout stopper 2 is a circular platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com