Base of a three-dimensional shelf

A technology of three-dimensional shelves and bottom plates, which is applied in the direction of display shelves, display hangers, display tables, etc., can solve the problems of insufficient strength, unsatisfactory load bearing, large welding deformation, etc., and achieve easy adjustment, large bearing tonnage, and reduced welding deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The base of a three-dimensional shelf of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

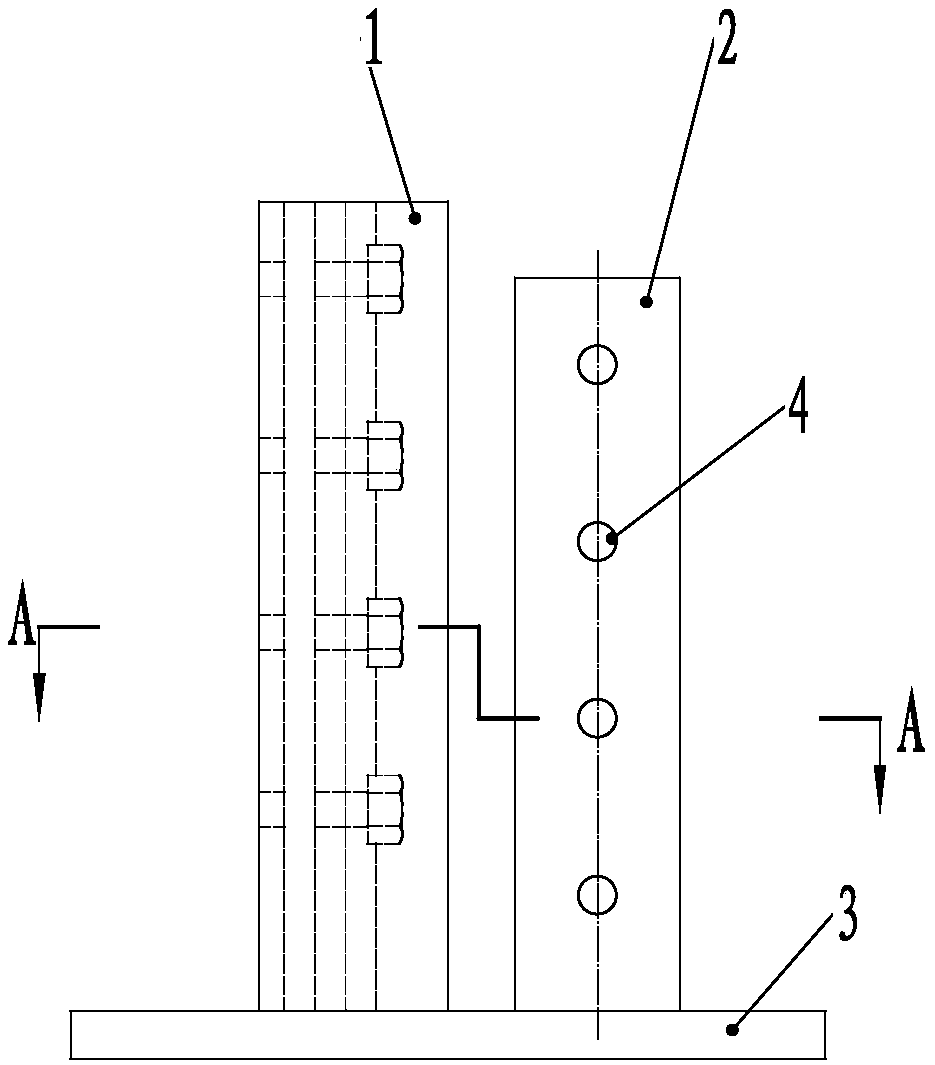

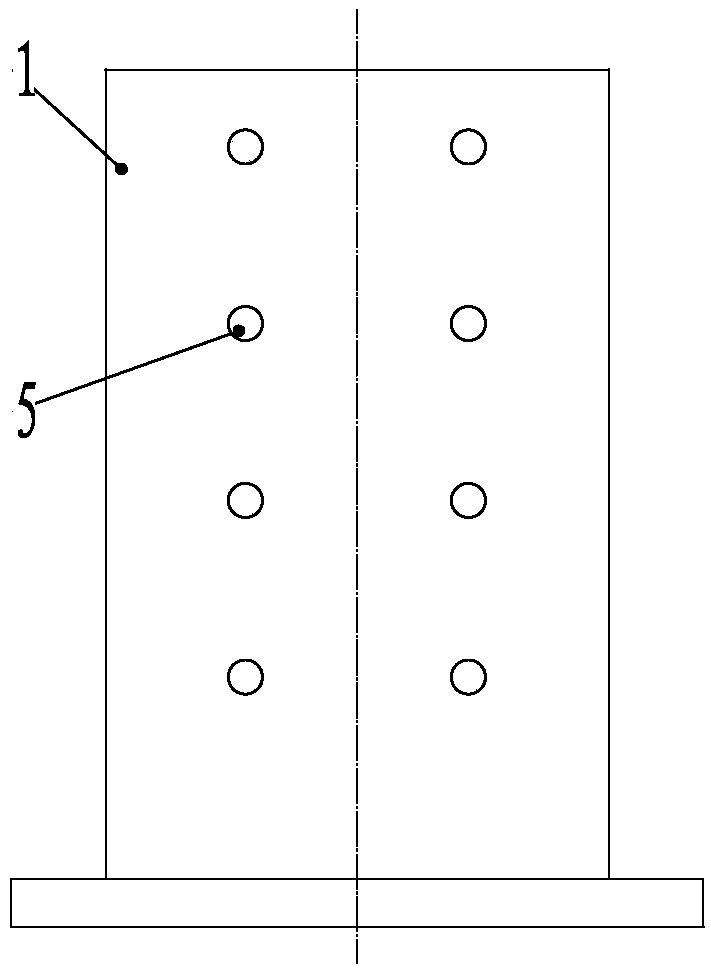

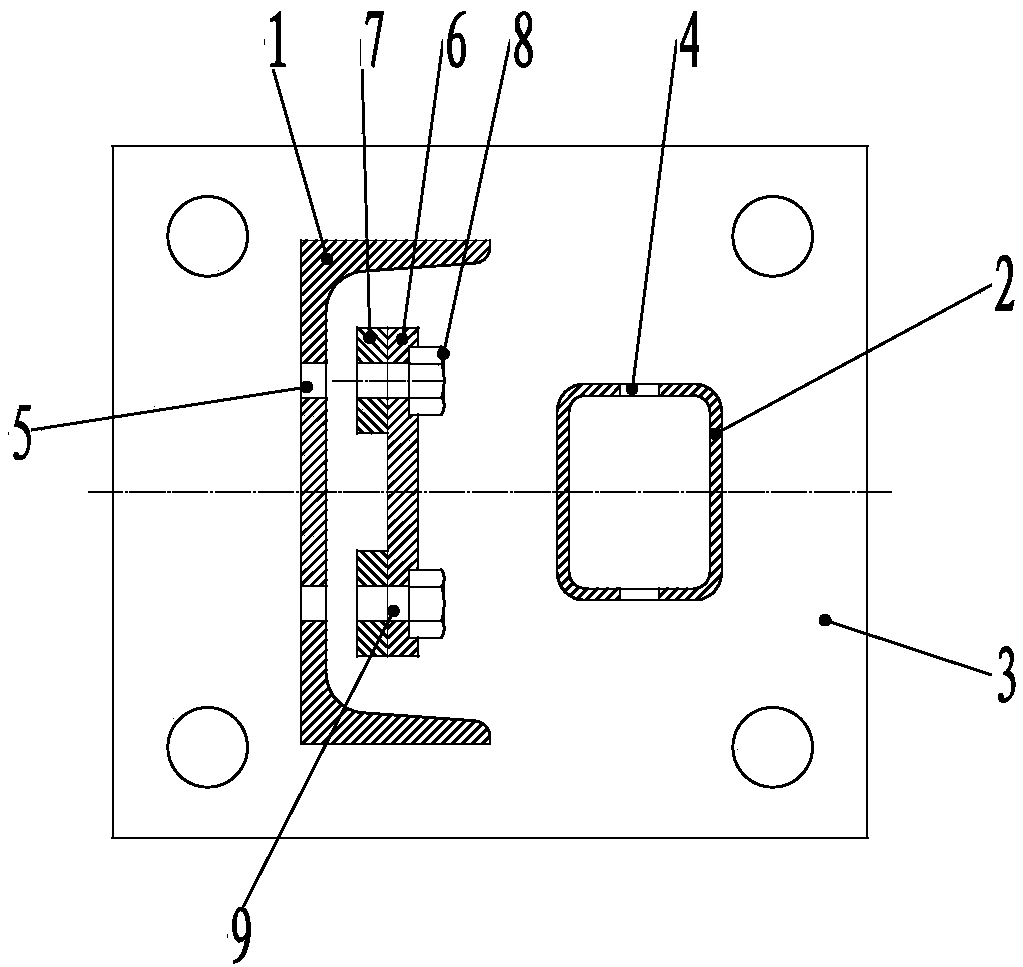

[0021] figure 1 It is a structural schematic diagram of the base of a three-dimensional shelf in the present invention, figure 2 yes figure 1 left view of image 3 yes figure 1 A-A sectional view in . In the figure, the base of the three-dimensional shelf includes a bottom plate 3. The bottom plate 3 is made of a steel plate of 240mm×220mm×20mm. The bottom plate 3 is provided with a U-shaped positioning column 1, and the bottom surface of the U-shaped groove of the U-shaped positioning column 1 is provided with a longitudinal A plurality of front connection holes 5 arranged, U-shaped positioning column adopts 16# U-shaped channel steel of 160mm * 65mm * 8.5mm to make. Base plate 3 is also provided with nut connecting plate 6, and nut connecting plate 6 is positioned at the middle part of the U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com