Double-layer piston type tensile and compression tensionmeter

A technology of piston type and tension gauge, applied in the field of dynamometer, can solve the problems that the press is difficult to clamp, bulky, and the tension gauge can only exert force in one direction, and achieve the effect of small diameter and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments are further described below according to the accompanying drawings.

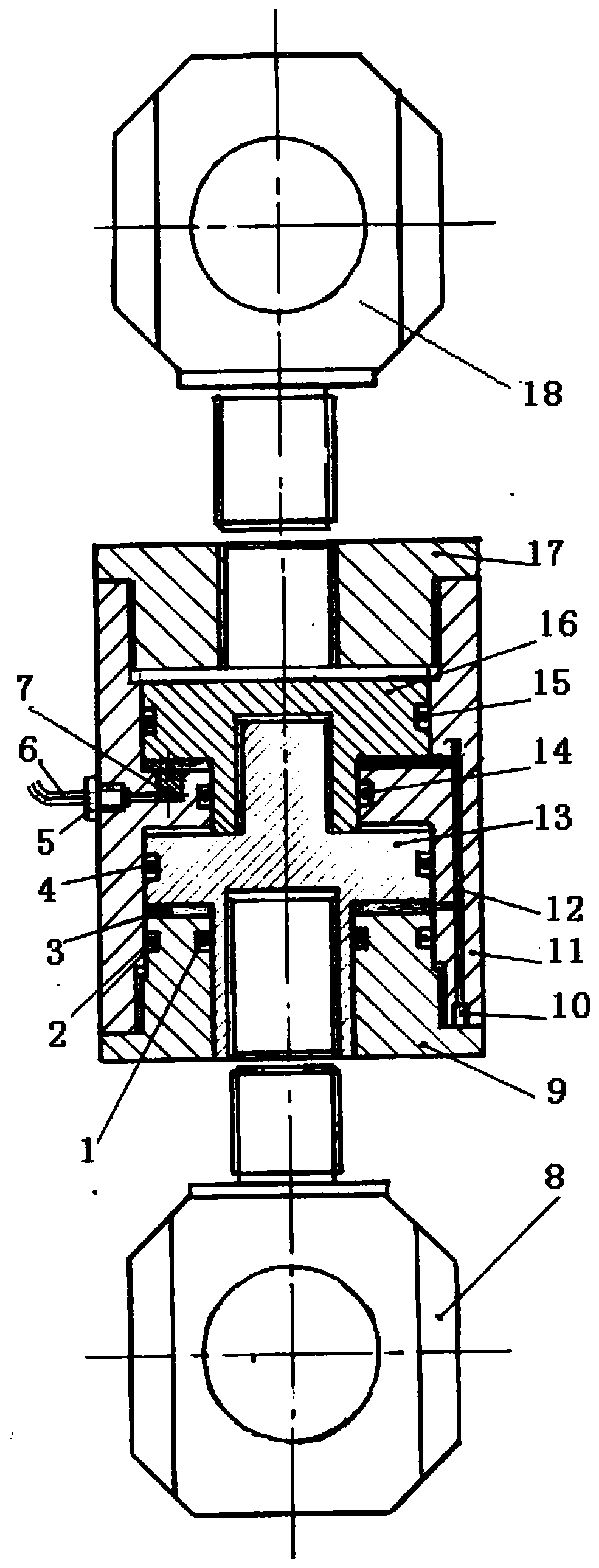

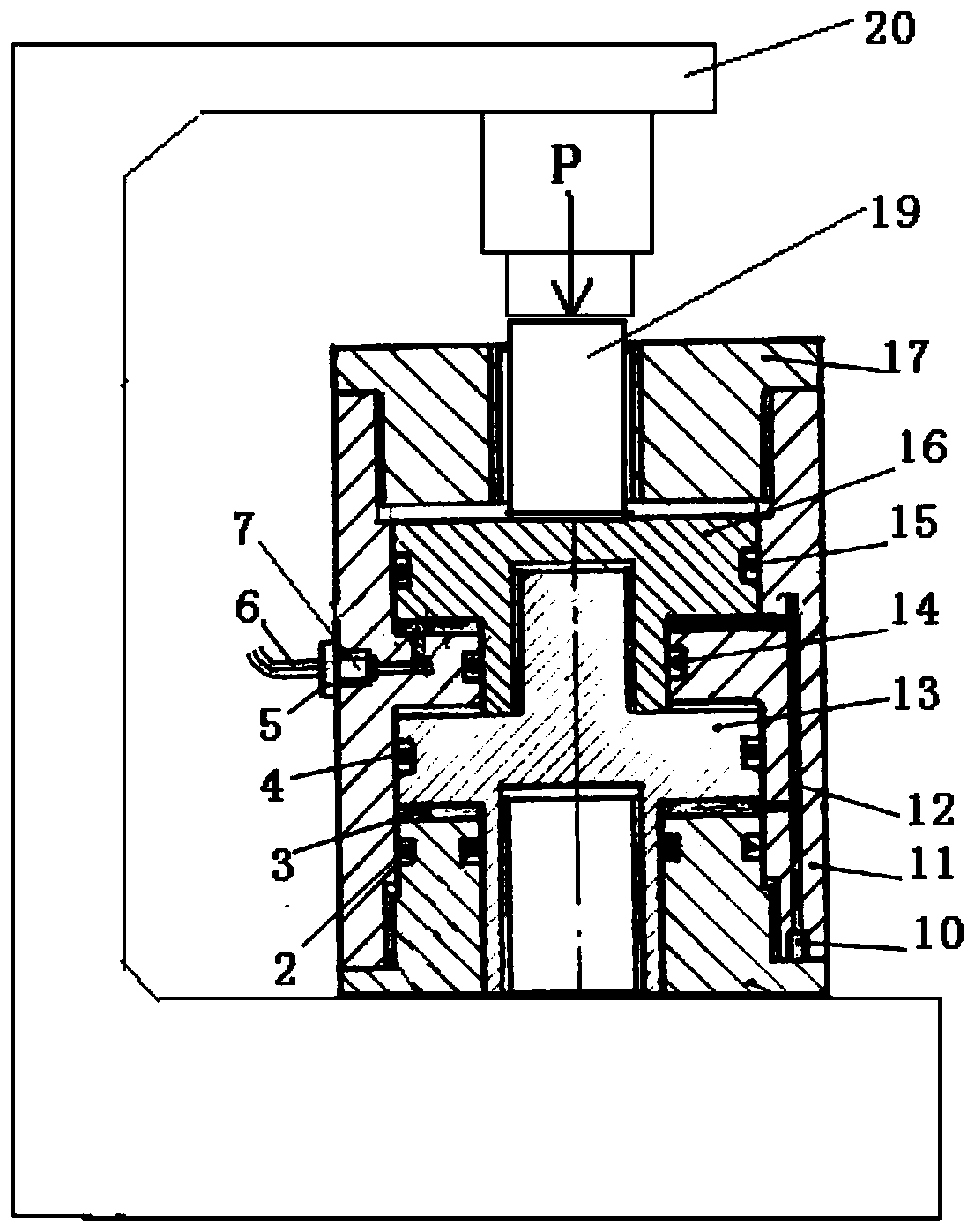

[0016] Such as figure 1 As shown, a double-layer piston type pull-compression dual-purpose tension meter consists of a cylinder body (including cylinder barrel 11 and cylinder bottom member 9), piston (including upper piston 16 and lower piston 13), grease 3, top cover 17 and The liquid pressure sensor 7 is formed; wherein, the cylinder bottom of the cylinder body is an independent part, that is, the cylinder body is composed of a cylinder barrel 11 and a cylinder bottom part 9, and the cylinder bottom part 9 is provided with a central round hole, and the cylinder bottom part 9 passes through Threaded on the lower opening of the cylinder barrel 11; the cylinder body is provided with a gap, and the gap is provided with a central round hole, so that the cylinder cavity forms two cylinder cavities connected up and down; the piston is two connected up and down. The T-shaped piston of solid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com