Liquid floated ball grinder

A ball mill and liquid floating technology, which is applied in the field of grinding equipment, can solve problems such as unfavorable replacement of the inner lining stone of the ball mill, difficult realization of the pulping process, and high safety requirements, and achieve simple design and production, good economic benefits, and sealing requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

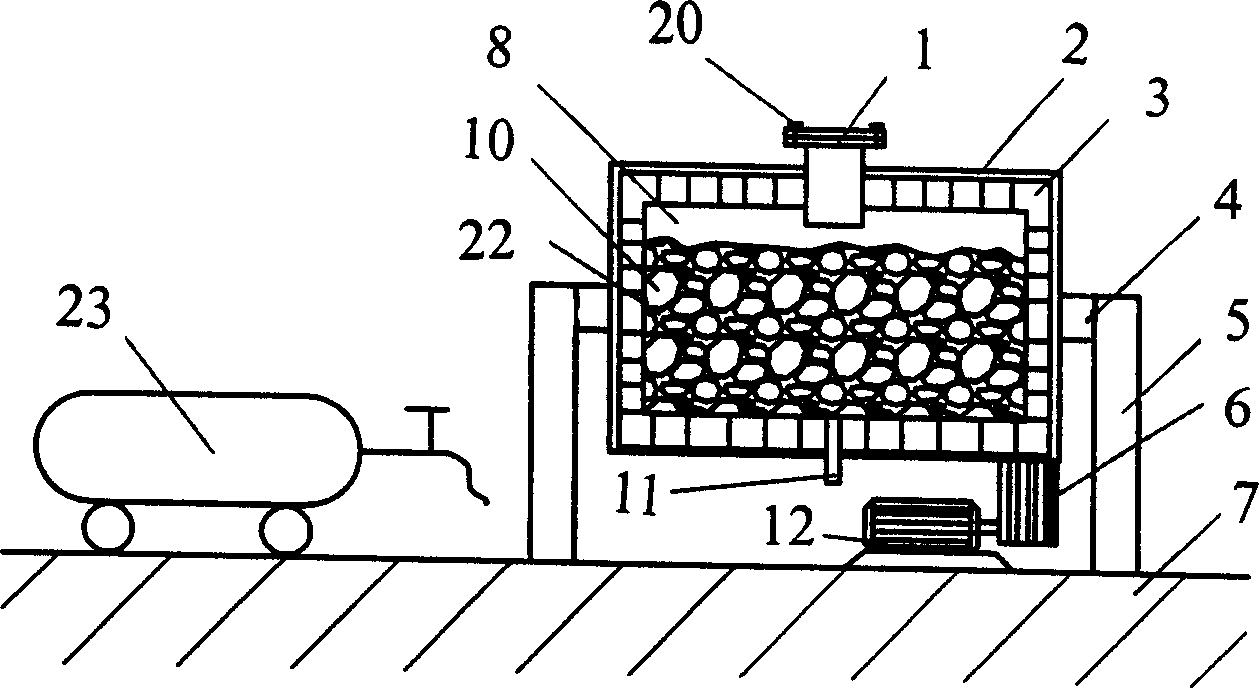

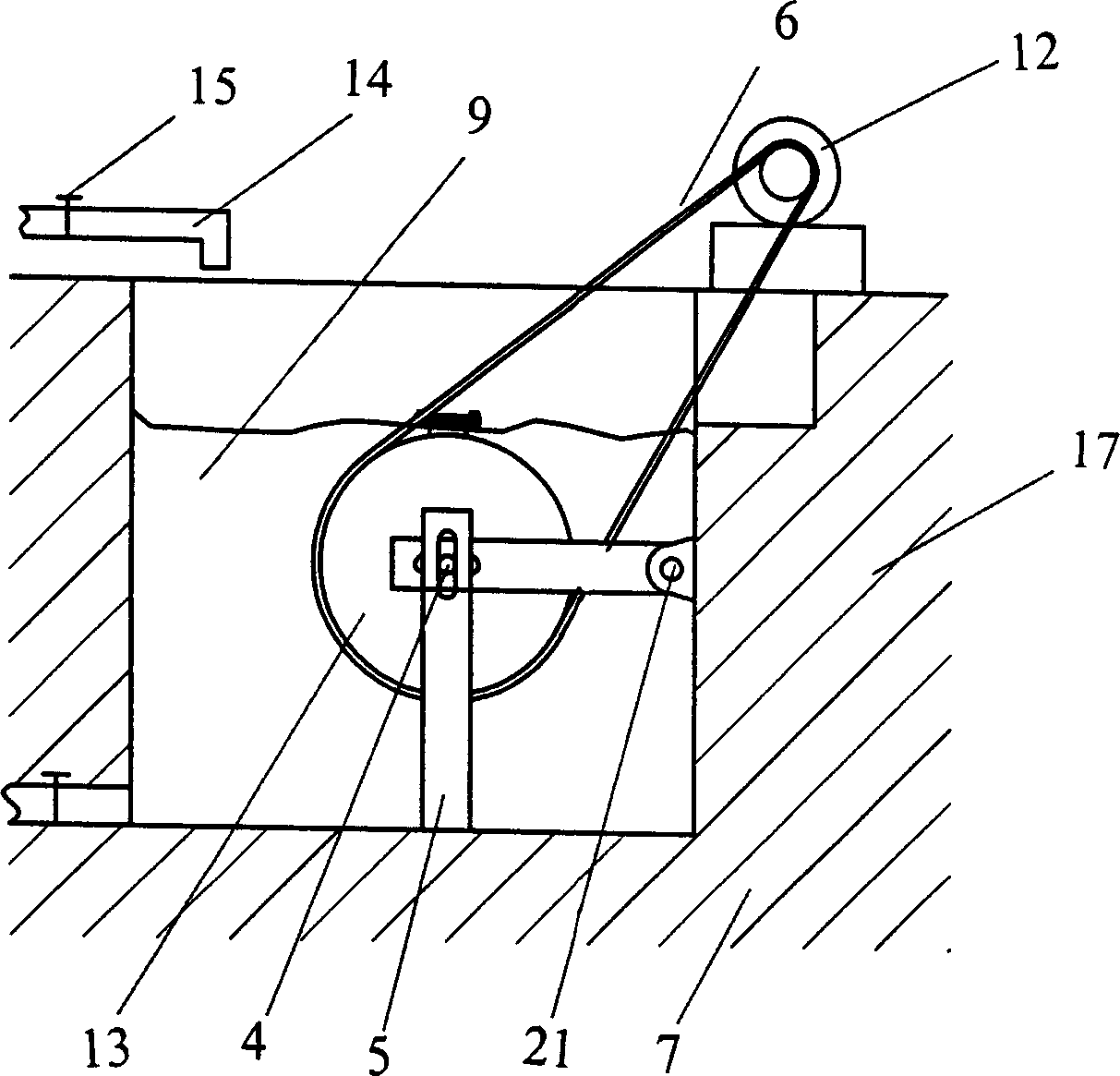

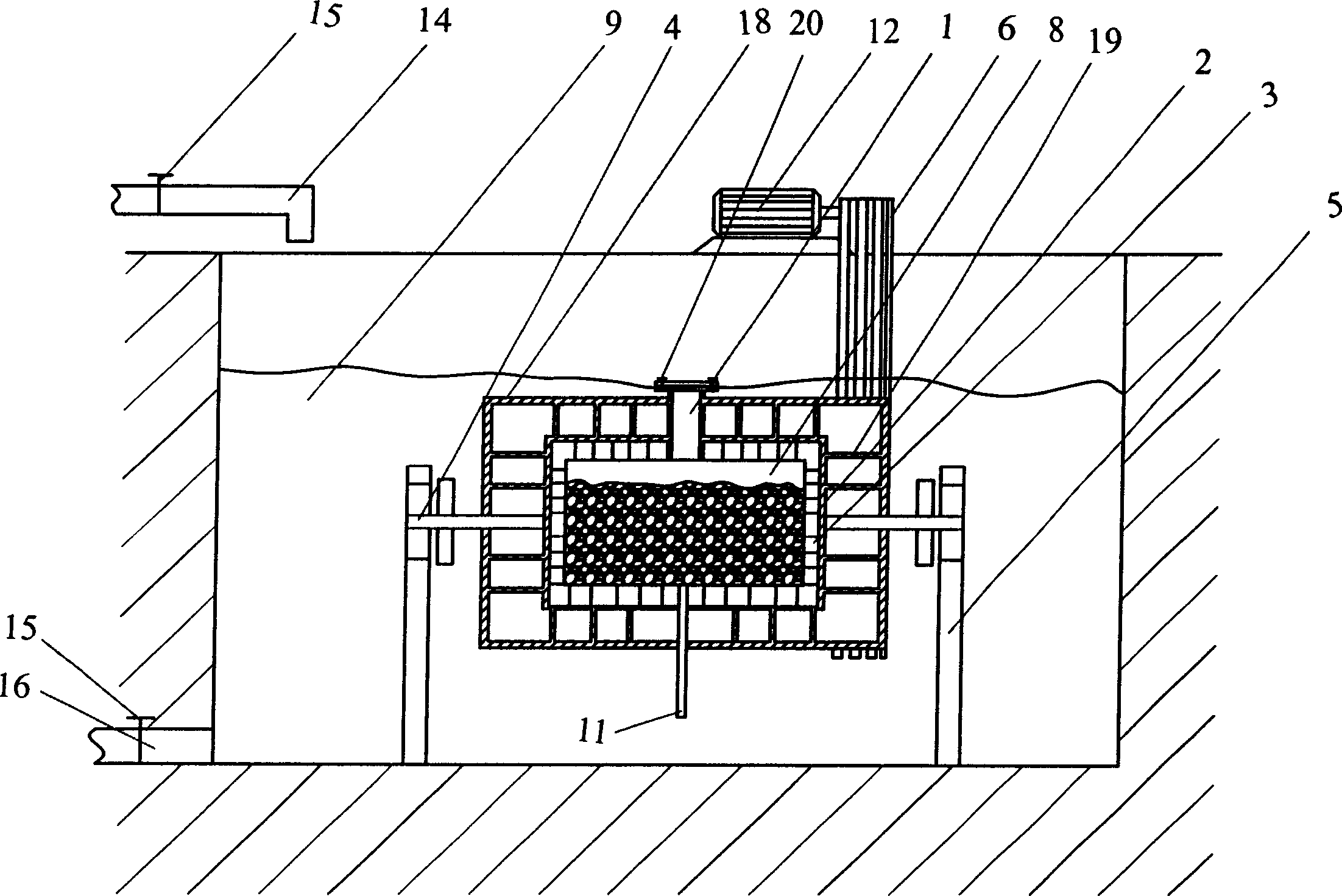

[0041] The features of the present invention can be further understood through the detailed description of the preferred embodiments in conjunction with the accompanying drawings.

[0042] Such as figure 2 and 3 As shown, the barrel 2 and the inner liner 3 are installed on the support 5, and can be rotated around the support shaft 4 on the support 5 through the transmission of the transmission system. The transmission system includes a motor 12 fixed on the side of the open liquid pool 17 and The belt connecting the motor 12 and the barrel 2, the liquid pool 17 is injected with liquid through the liquid filling pipe 14, and the liquid can also be discharged out of the liquid pool 17 through the liquid discharge pipe 16. The liquid is selected according to the different materials to be ground and the required specific gravity of the liquid. In this embodiment, water is preferred, and of course lubricating oil or other liquids can also be selected. The support 5 is fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com