Manufacturing method of aluminum silicon target

A production method, the technology of aluminum-silicon target, which is applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problems of reducing processing performance, anisotropy of forgings, and affecting the quality of film formation, so as to ensure the mechanical performance, prevention of cracking, effects of avoiding the formation of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0021] A method for manufacturing an aluminum-silicon target in this embodiment includes the following steps,

[0022] 1) Provide an AlSi ingot casting step, the purity of the AlSi ingot casting is 99.999%, wherein the percentage by weight of Si element is ≤4%.

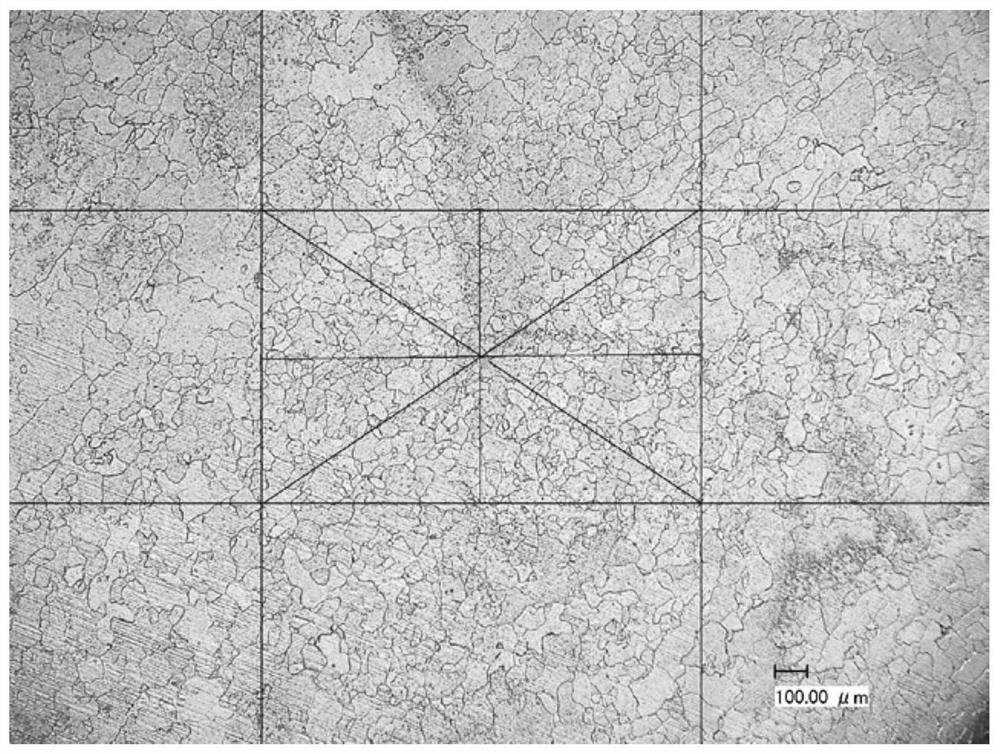

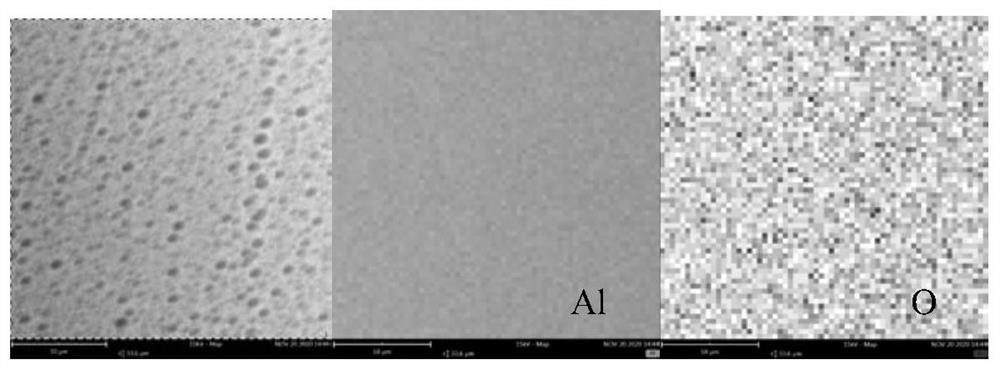

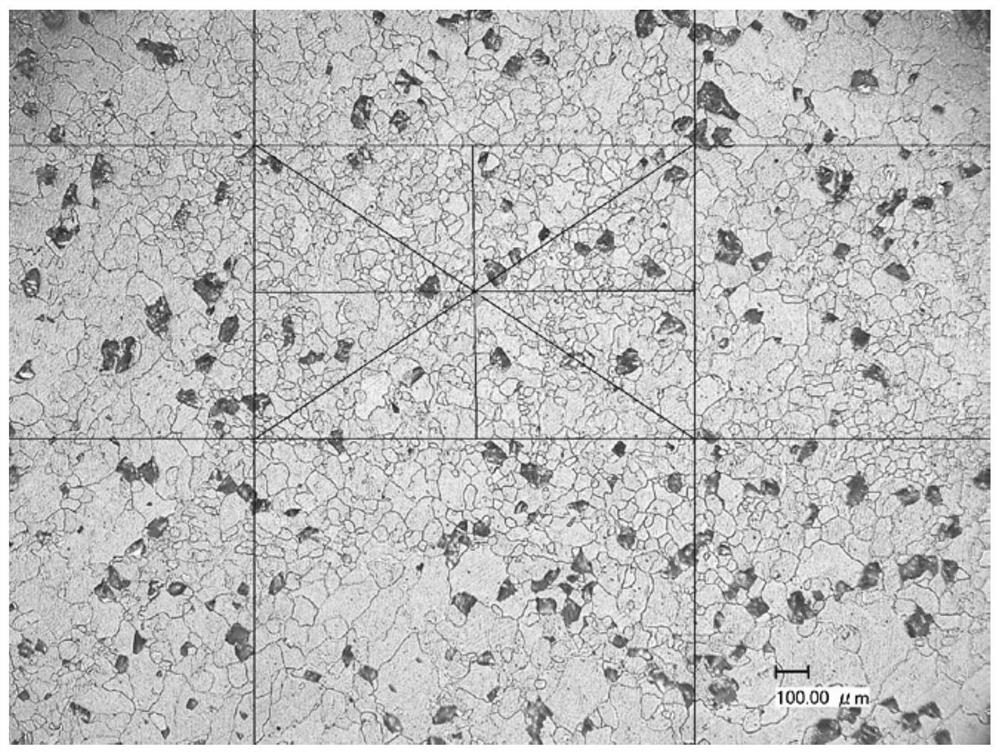

[0023] 2) Elongation step: the AlSi ingot 1 is elongated. The elongation means applying pressure along the vertical axis of the ingot to make the diameter of the ingot smaller and the length longer to form the product 2 . And there is no heating during the drawing process, which is a cold drawing operation. Wherein the forging ratio in the cold drawing operation is X1, 1≤X1<2. After dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com