Forming tool and forming method for circumferential non-closed variable-cross-section cylindrical part

A technology of variable cross-section and parts, applied in the field of compound forming of sheet metal and pipe fittings, to achieve the effects of simplifying forming process, reducing manufacturing cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

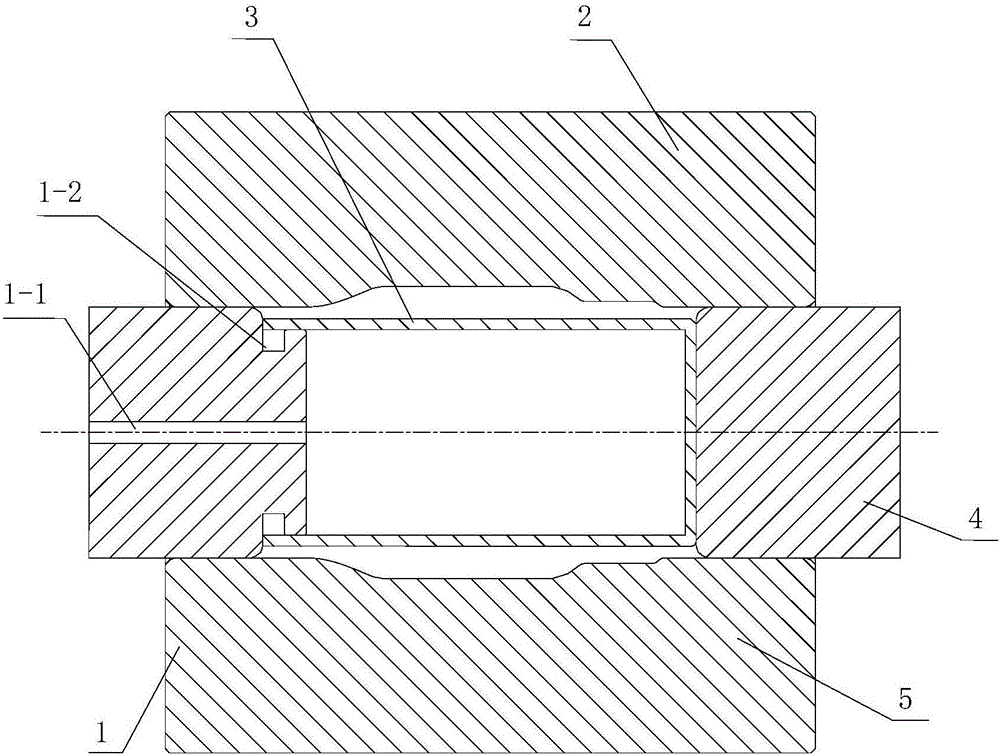

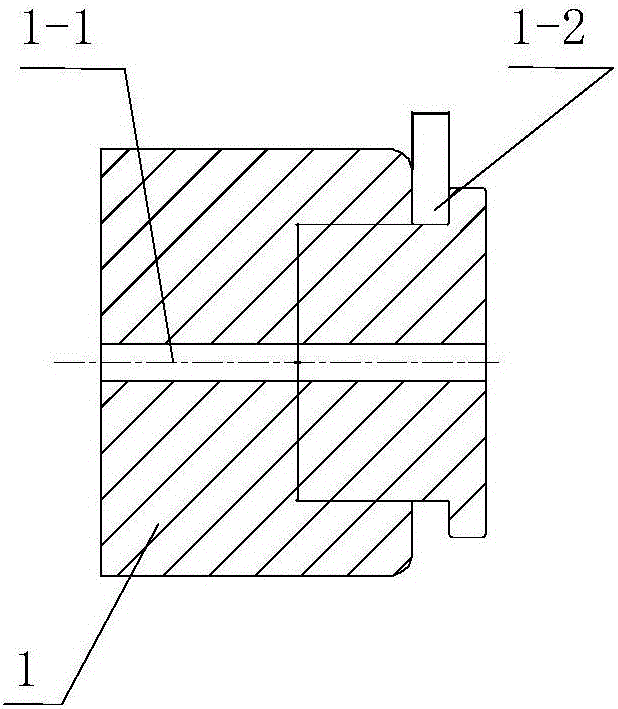

[0039] Example 1, see Figure 1-Figure 7 ,

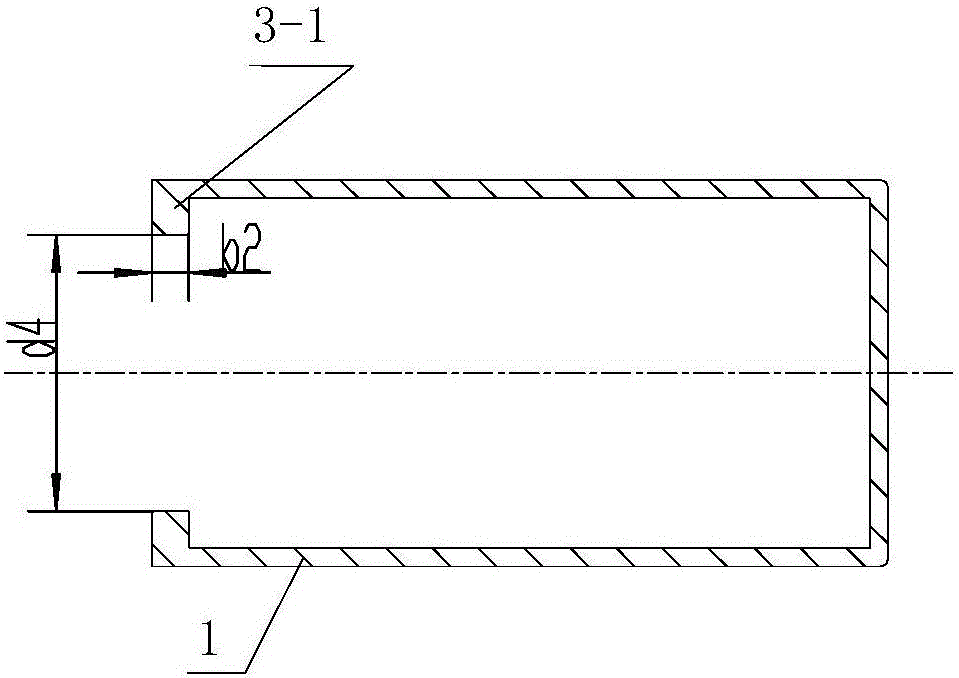

[0040] Tooling for forming cylindrical parts with non-closed variable cross-section in the circumferential direction, including a first sealing head 1, a second sealing head 4, a liquid-filled bladder 3, an upper mold 2 and a lower mold 5, and the first sealing head is provided with a liquid filling device. A liquid inlet 1-1 and an annular groove 1-2 for accommodating a liquid-filled bag, one end of the liquid-filled bag is an open end, and a sealing flange 3-1 for connection and sealing is formed on the open end, so The opening end of the liquid-filled bag is set on the first sealing head, and is embedded in the groove 1-2 of the first sealing head through the sealing flange, and the liquid-filled bag is located by the first sealing head 1, the second In the mold cavity that sealing head 4, upper mold 2 and lower mold 5 constitute.

[0041] In this embodiment, the width b1 of the annular groove on the first sealing head ≤ the wi...

Embodiment 2

[0051] Example 2, see Figure 1-Figure 3 , Figure 8 ,

[0052] A method for forming a circumferential non-closed variable-section cylindrical part using tooling for forming a circumferential non-closed variable-section cylindrical part, comprising the following steps:

[0053] S1. Install the lower mold, upper mold, first sealing head, liquid-filled bladder and second sealing head on the forging machine tool according to the design requirements, the lower mold and the press table are fixed, and the upper mold moves up to the set height. The first sealing head on which the liquid-filled bladder is fixed moves away from the second sealing head, so that enough space is left between the upper mold and the lower mold to place the blank.

[0054] S2. The blank in this forming method is a flat sheet. First, roll the flat sheet into a cylindrical or semicircular shape by hand or machine. After rolling, wrap Teflon or plastic film on the outside of the blank to maintain the shape of...

Embodiment 3

[0058] Example 3, see Figure 1-Figure 3 , Figure 9 ,

[0059] Tooling for forming cylindrical parts with non-closed variable cross-section in the circumferential direction, including a first sealing head 1, a second sealing head 4, a liquid-filled bladder 3, an upper mold 2 and a lower mold 5, and the first sealing head is provided with a liquid filling device. A liquid inlet 1-1 and an annular groove 1-2 for accommodating a liquid-filled bag, one end of the liquid-filled bag is an open end, and a sealing flange 3-1 for connection and sealing is formed on the open end, so The opening end of the liquid-filled bag is set on the first sealing head, and is embedded in the groove 1-2 of the first sealing head through the sealing flange, and the liquid-filled bag is located by the first sealing head 1, the second In the mold cavity that sealing head 4, upper mold 2 and lower mold 5 constitute.

[0060] In this embodiment, the width b1 of the annular groove on the first sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com