Double-chamber hydragass spring

A technology of oil-pneumatic springs and double air chambers, applied in springs, spring/shock absorbers, gas-hydraulic shock absorbers, etc., can solve problems such as troublesome maintenance, inconvenient installation and layout, and gas leakage, and achieve convenient maintenance and structural Simple, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

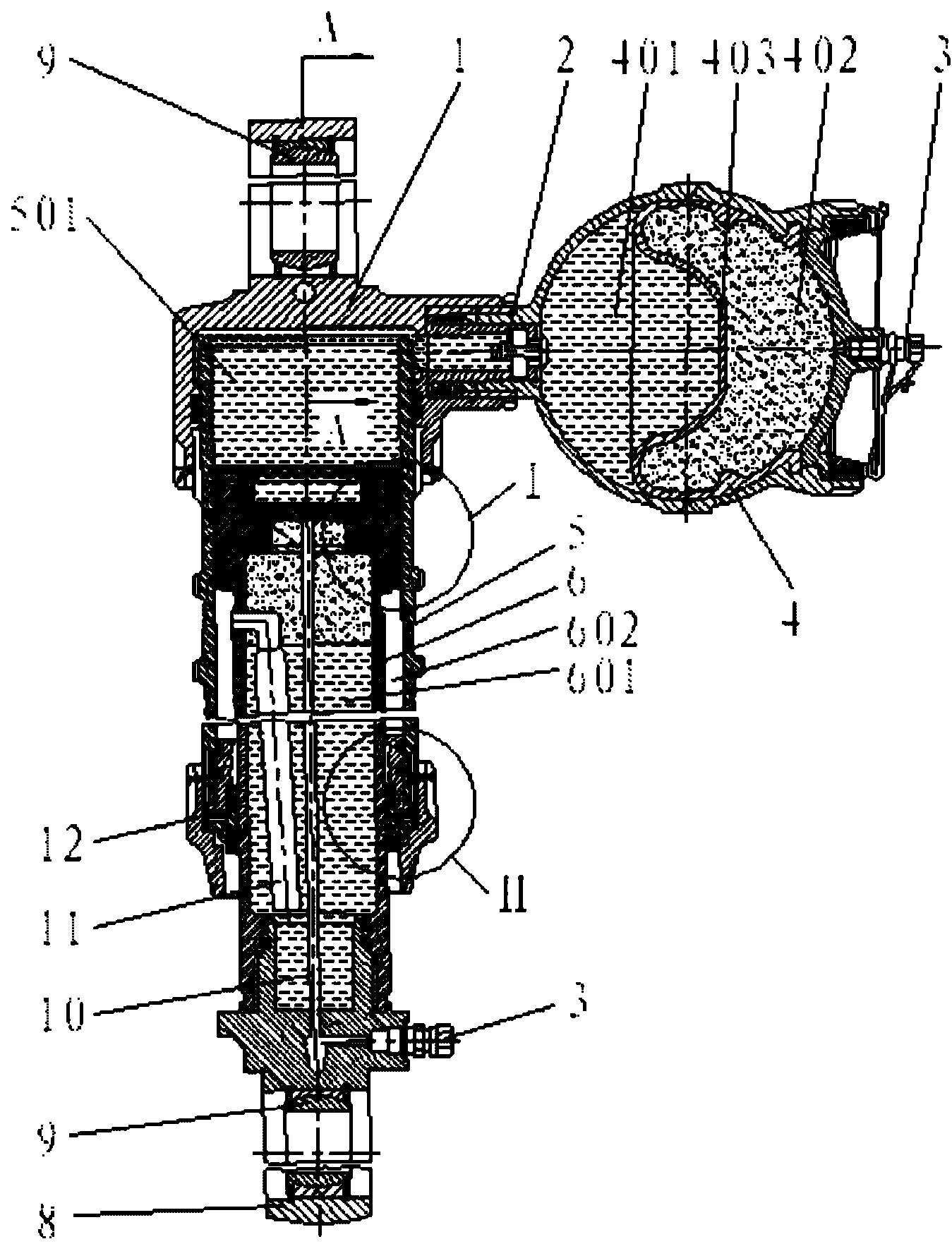

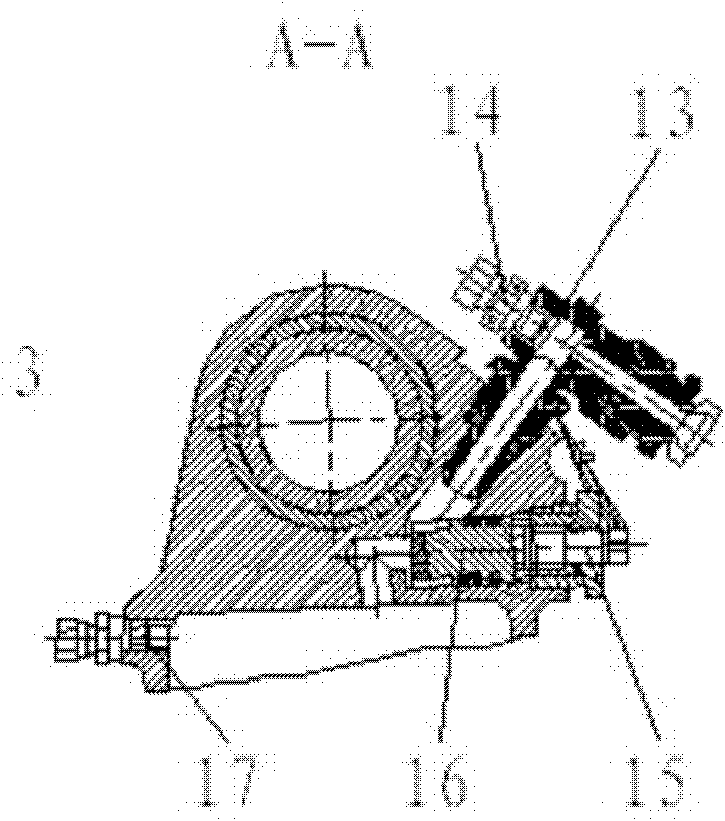

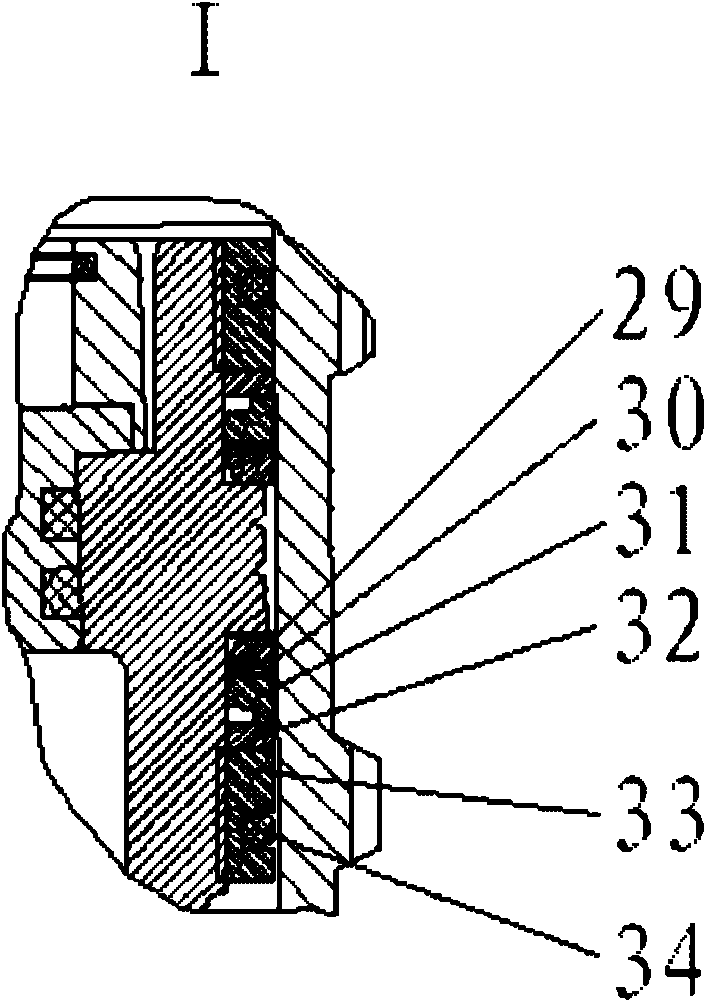

[0018] Such as figure 1 As shown, a double-chamber oil-pneumatic spring mainly includes an upper lug 1, a lower lug 8, a master cylinder 5, an elastic component 4, a back pressure cylinder 6, a piston and a guide pipe 10 and the like. The upper lug 1 is located at the top of the master cylinder 5, and the lower lug 8 is located at the bottom of the back pressure cylinder 6, and they are connected by a threaded structure. Bearings 9 are installed inside the upper lug 1 and the lower lug 8, the side of the upper lug 1 is connected with the elastic part 4, the piston and the guide tube 10 are installed in the back pressure cylinder 6, and the back pressure cylinder 6 is integrated with the piston and the guide tube 10 And installed in the cylinder body of the master cylinder 5, the space between the upper surface of the piston and the master cylinder 5 and the space below the upper lug 1 together forms the main chamber 501, the main chamber 501 and the elastic member oil chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com