Hydraulic lifting travelling crane

A hydraulic and driving frame technology, which is applied in cranes, trolley cranes, transportation and packaging, etc., can solve the problems of combustion, danger, and easy to generate electric sparks, etc., and achieve large movable space, large lifting tonnage, and small installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

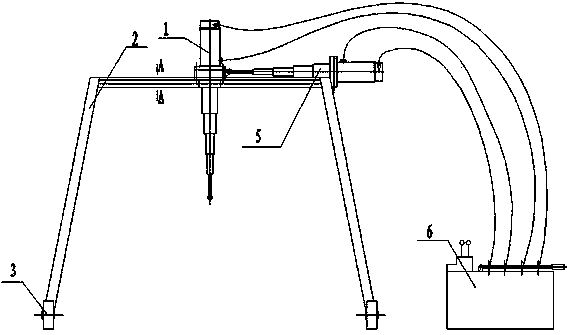

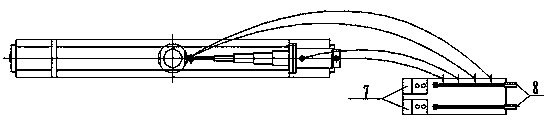

[0014] like figure 1 , 2 As shown in and 3, the hydraulic lifting crane of the present invention includes a lifting cylinder 1 and a traveling device, and the traveling device includes a traveling frame 2 and a traveling wheel 3 arranged at the bottom of the traveling frame 2, and the traveling frame 2 is provided with There is a sliding groove 4, the lifting cylinder 1 is provided with a mounting flange, the mounting flange is snapped into the sliding groove 4 and can move along the length direction of the sliding groove 4, and one side of the walking device is provided with a horizontal cylinder 5. The piston rod of the horizontal cylinder 5 is hinged to the lifting cylinder 1. The horizontal cylinder 5 and the lifting cylinder 1 are connected to the manual reversing hydraulic system 6 through pipelines. When the manual reversing hydraulic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com