Control method of roller washing machine

The technology of a drum washing machine and its control method is applied to the control device of the washing machine, the washing device, textiles and paper making, etc., which can solve the problems of time-consuming overall work, easy to get stuck in the laundry, etc., and achieve automatic and coherent laundry processing procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

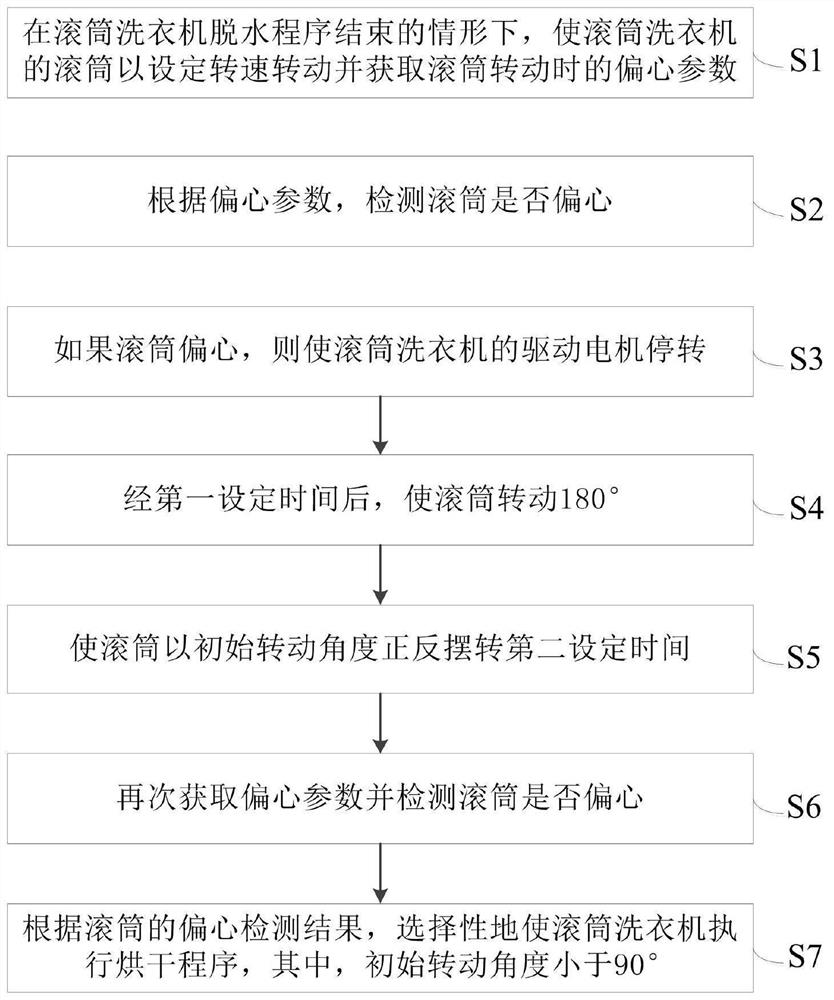

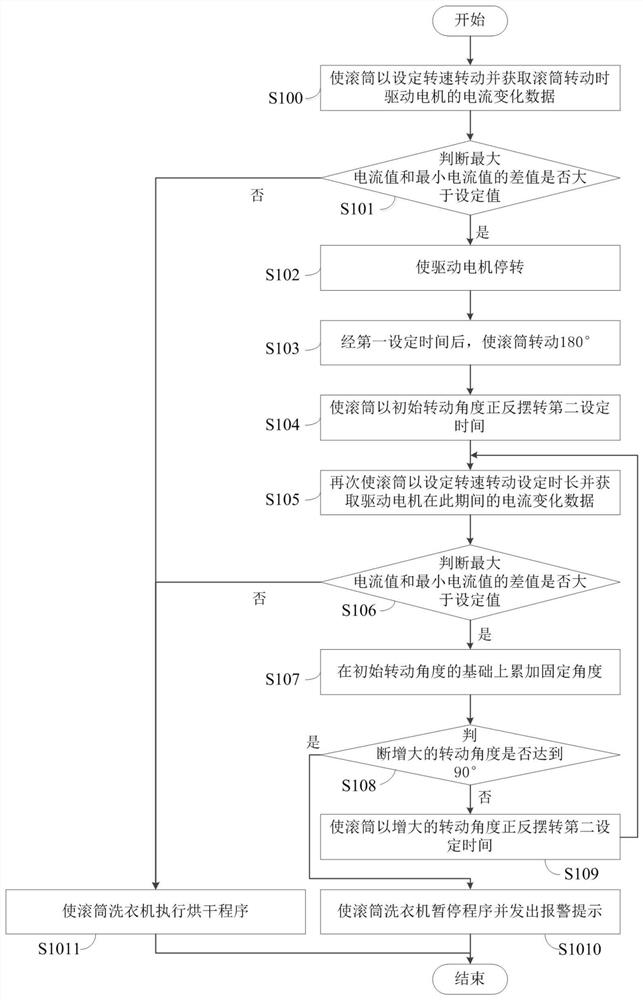

[0070] see again image 3 , image 3 It is a detailed step-by-step flow chart of a preferred embodiment of the control method of the drum washing machine of the present invention. Such as image 3 Shown, preferred embodiment of the present invention comprises the following steps:

[0071] Step S100: When the dehydration program of the drum washing machine is finished, make the drum rotate at a set speed for a set time and obtain the current change data of the drive motor during this period;

[0072] Step S101: judging whether the difference between the maximum current value and the minimum current value is greater than a set value;

[0073] If the difference between the maximum current value and the minimum current value is greater than the set value, execute step S102, otherwise execute step S1011;

[0074] Step S102: stop the driving motor;

[0075] Step S103: after the first set time, make the drum rotate 180°;

[0076] Step S104: making the drum rotate forward and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com