Wall-hanging hydrostatic level mounting device and wall-hanging hydrostatic level mounting method

A technology of a static level and an installation device, which is applied in the direction of hydrostatic pressure and the like, can solve the problems of difficult leveling of the wall-mounted static level, uneven sidewall of the installation site, and difficulty in controlling the hole formation of bolts. Complete positioning installation and leveling work, saving installation and leveling time, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

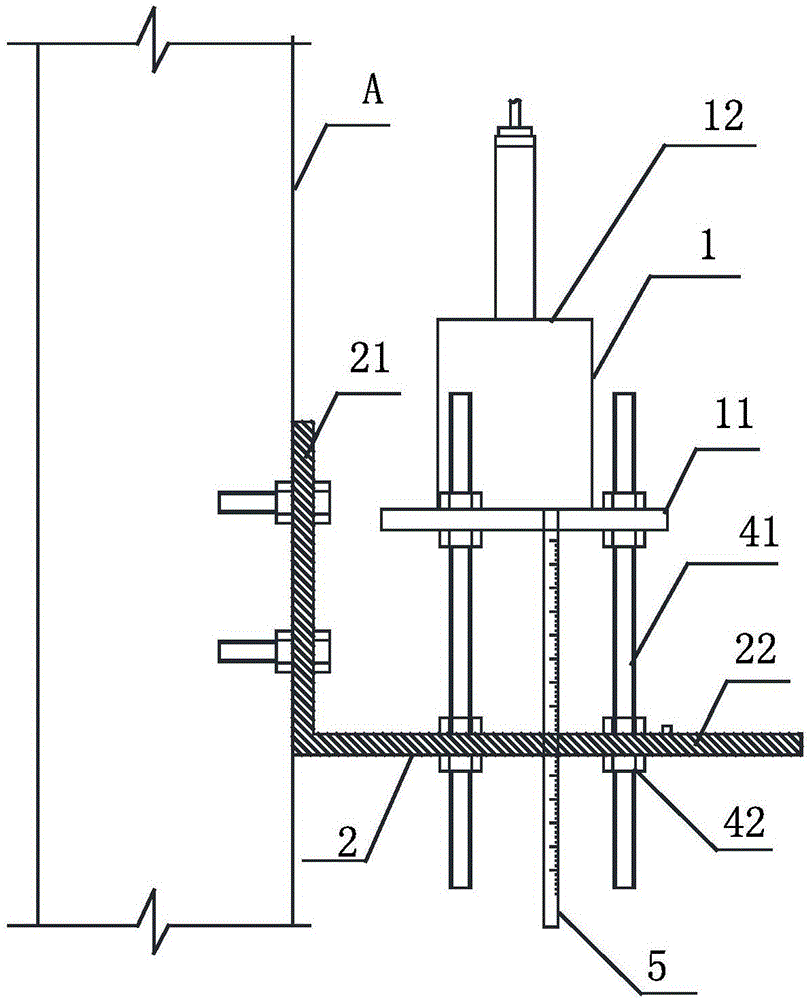

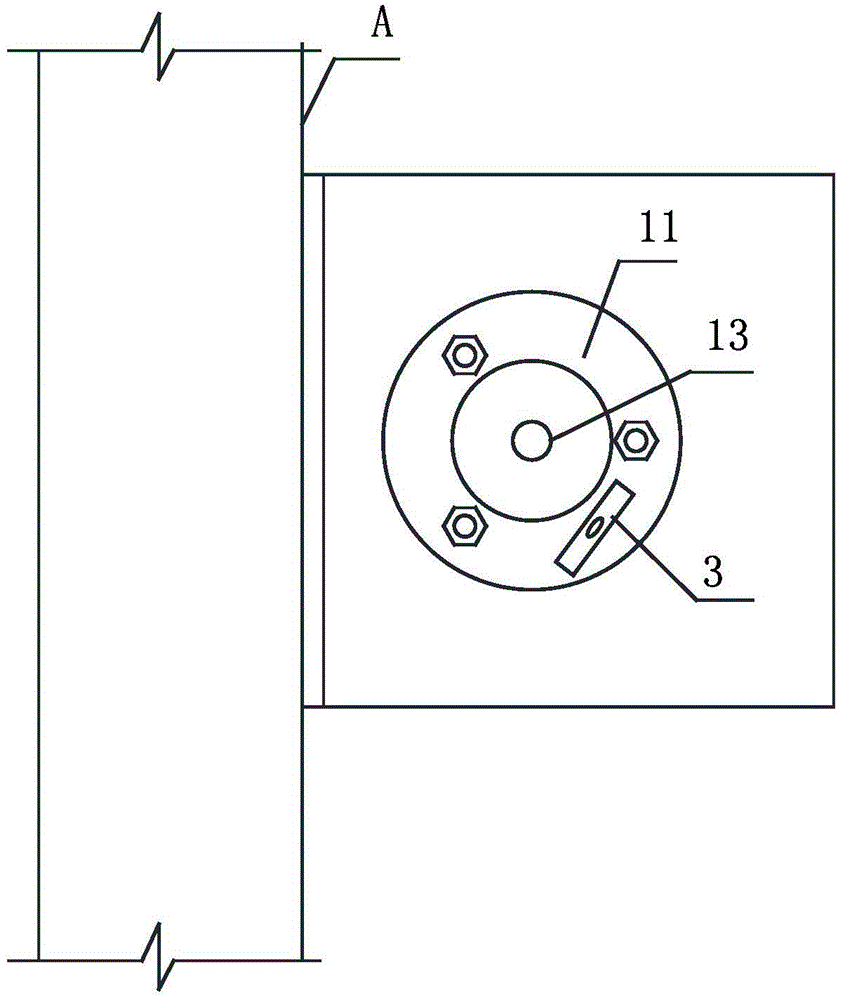

[0027] Embodiment one: combine below figure 1 and figure 2 The installation device and method of the wall-mounted static level of the present invention will be described in detail.

[0028] Such as figure 1 and figure 2 As shown, the installation device of the wall-mounted static level 1 includes an L-shaped fixed frame 2. The L-shaped fixed frame 2 is composed of a vertical side plate 21 and a horizontal side plate 22 fixed vertically. The vertical side plate 21 is connected with the wall A by bolts, and the lateral side plate 22 is provided with three threaded holes corresponding to the base 11 of the wall-mounted static level 1 and a through hole; a bubble level 3, which is fixedly installed on the hanging Above the base 11 of the wall-type static level 1; an adjustment frame, the adjustment frame is a triangular frame with three threaded rods 41 and corresponding nuts 42 vertically formed, the base 11 of the wall-mounted static level 1 and the adjustment frame and a ...

Embodiment 2

[0035] Embodiment 2: Continue to refer to below Figure 1 to Figure 2 , detailing the installation method of the wall-mounted static level of the present invention. Taking the installation of a wall-mounted static level 1 as an example, the installation method of the wall-mounted static level 1 includes the following steps:

[0036] First, a bolt hole corresponding to the vertical side plate 21 is opened at a predetermined installation position on the wall A, and the vertical side plate 21 of the L-shaped fixing frame 2 is bolted to the wall A so that the lateral side plate 22 remains horizontal.

[0037] Specifically, during installation, mark the corresponding position on the wall A by laser method or rope pulling method, and preliminarily determine the predetermined installation positions of multiple wall-mounted static levels 1 . Then complete the installation of each wall-mounted static level 1 in turn. Of course, in order to ensure the firmness of the installation betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com