Fusion splicing technological process and equipment for hollow drawstring of air bed body

A process method and bed body technology, applied in the field of inflatable bed body draw tape welding technology and welding equipment, can solve the problem that the position of the inner mold cannot be directly observed, cannot be adapted to mass production, and the weld line 105 patterns on the surface of the bed body are blurred, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

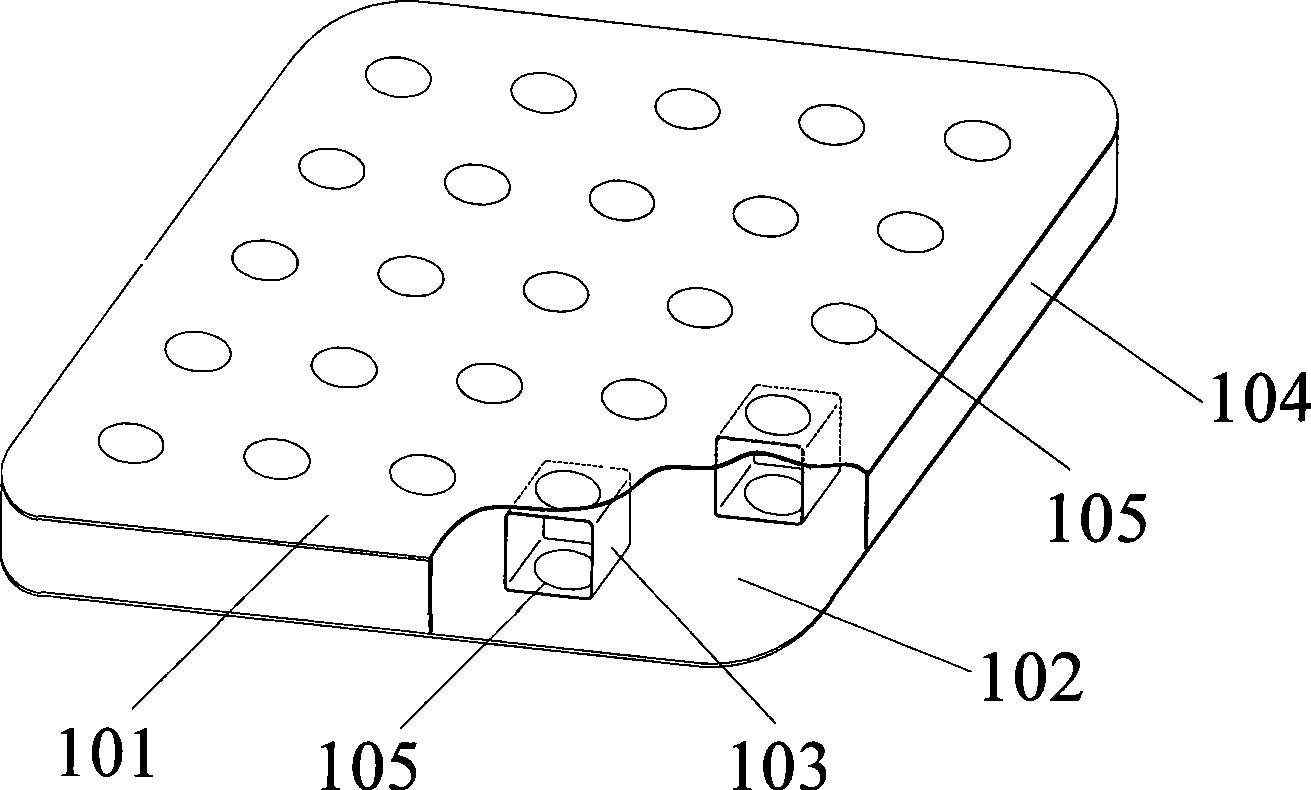

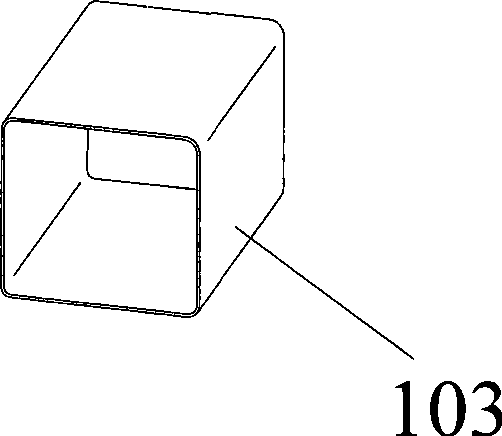

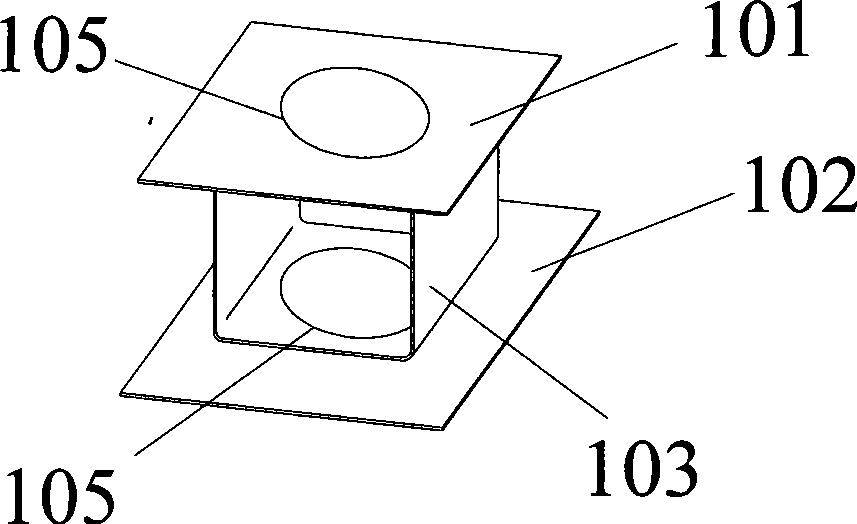

[0037] Such as Figure 6 As shown, the inflatable bed hole pull belt welding equipment of the present invention includes a frame 8, a high-frequency generator, an upper machine 10, a lower machine 11, a material delivery system, a high-frequency generator, an upper machine 10, and a lower machine. 11. The material conveying system is installed on the frame 8. The upper machine platform 10 and the lower machine platform 11 are respectively driven up and down by the cylinder 12. The bottom surface of the upper machine platform 10 and the top surface of the lower machine platform 11 are respectively installed with a certain number of The upper heat transfer mold 4 and the lower heat transfer mold 5 arranged in position and arrangement.

[0038] When working, the bed body and the hole pull belt 1 to be welded are sent to the frame 8 through the material delivery system, the upper heat transfer mold 4 and the lower heat transfer mold 5 clamp the bed body, and the upper heat transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com