Space optical remote sensor main bearing plate structure adopting embedded part

A technology of space optical remote sensing and main bearing plate, applied in the field of space optical remote sensing, can solve the problems of mutual separation and destruction of embedded parts and carbon fiber materials, small contact area of installation surface, small effective contact area, etc., to increase effective contact Area, enhanced structural rigidity and structural strength, and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

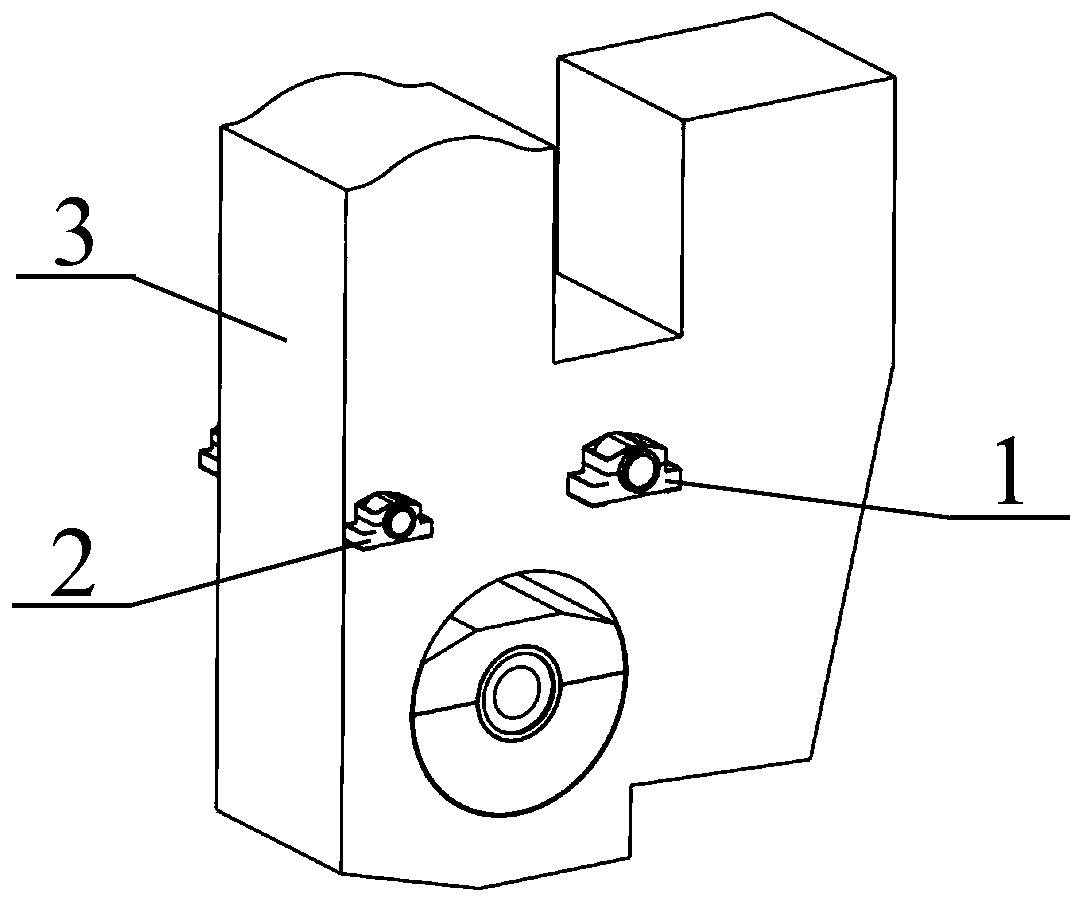

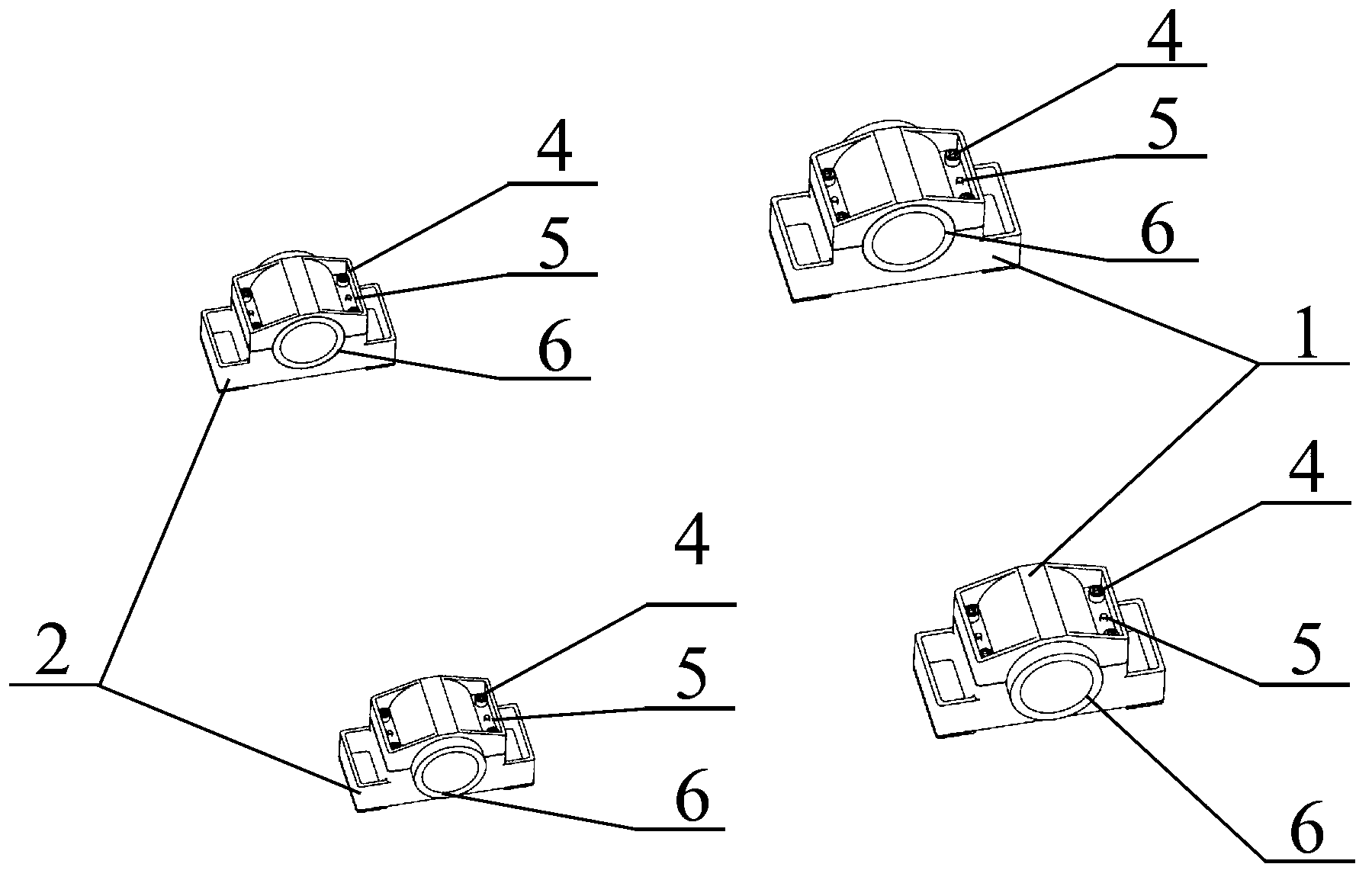

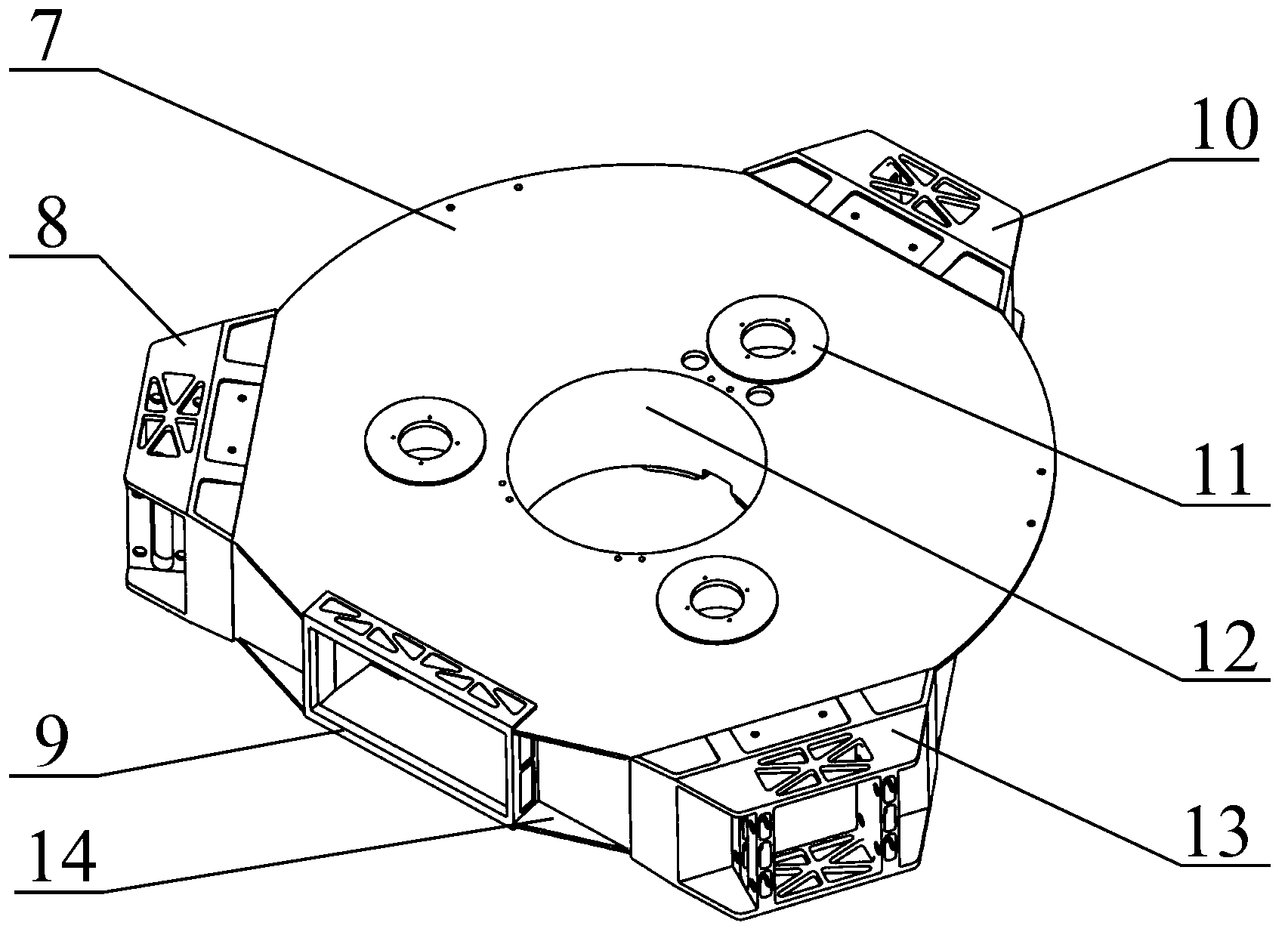

[0015] The invention according to Figure 3 to Figure 7 The implementation of the shown structure, the technical solution of the present invention includes: the main bearing plate 7, the first truss embedded block 8, the third mirror embedded block 9, the second truss embedded block 10, the main mirror embedded block 11, the main bearing plate Central light hole 12, third truss embedded block 13, main bearing plate lower surface 14, folding mirror embedded block 15, bias current embedded block 16, main mirror embedded block inlay hole 17, longitudinal rib groove 18, transverse rib groove 19 , 20 transverse ribs, 21 longitudinal ribs. Among them, the main bearing plate 7 is made of carbon fiber composite material, and all embedded parts are made of titanium alloy material. When manufacturing the main bearing plate 7, the design of mutual inlay and integral molding is adopted, and the transverse ribs 20 and longitudinal ribs 21 of the main mirror embedding block 11 are embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com