Truss concrete superposed beam

A technology of concrete and composite beams, which is applied to structural elements, building components, and long-strip structural components for load-bearing, etc., can solve problems such as difficult control of construction quality, restricted floor construction speed, and limited shelving length, etc., to achieve The effect of reducing labor and material costs, simple and fast on-site construction, and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

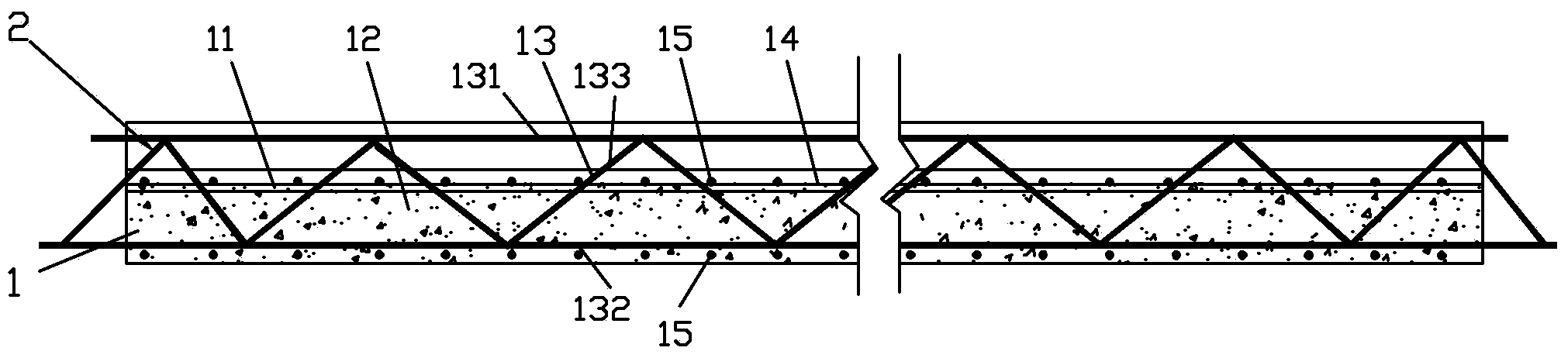

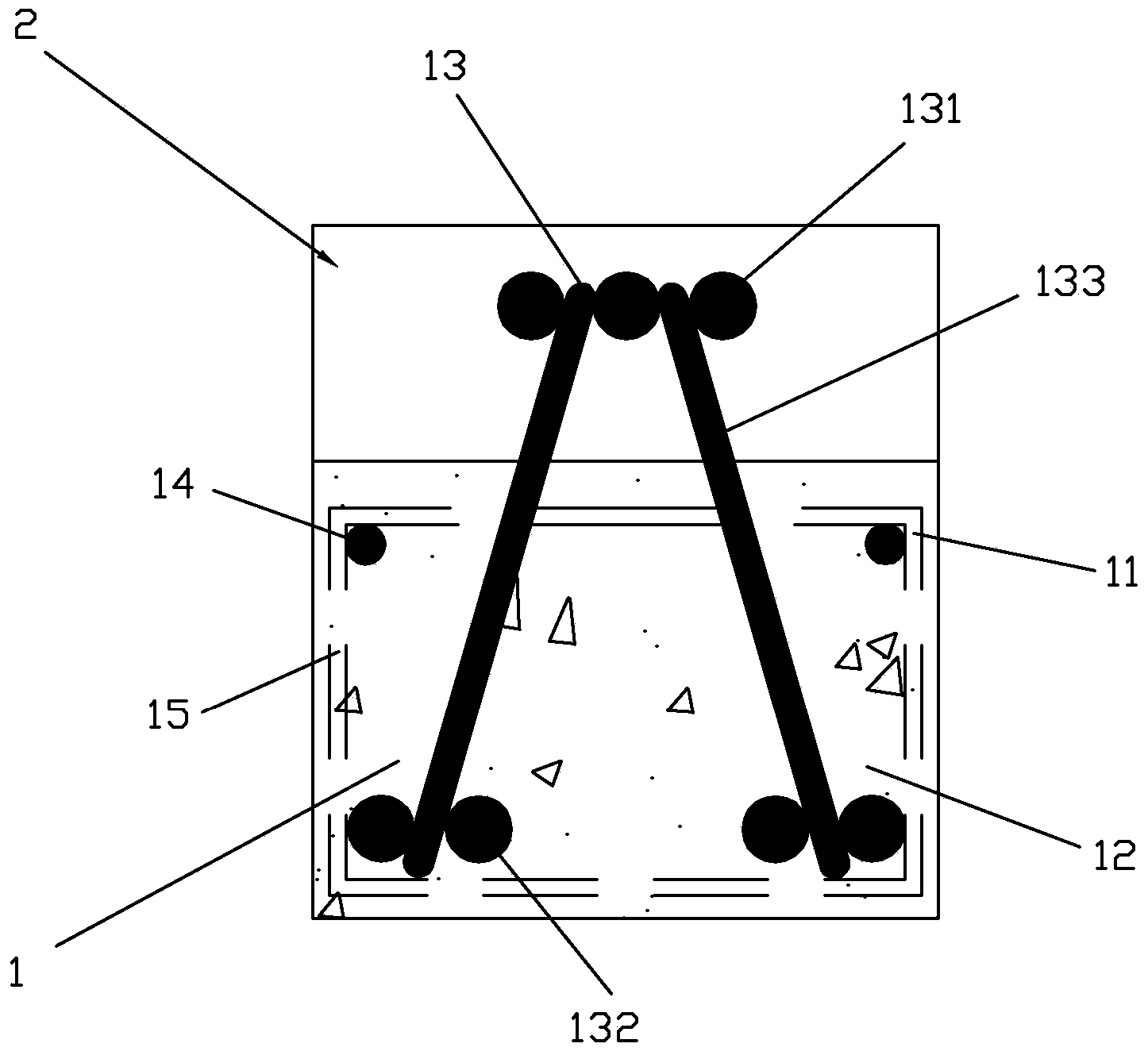

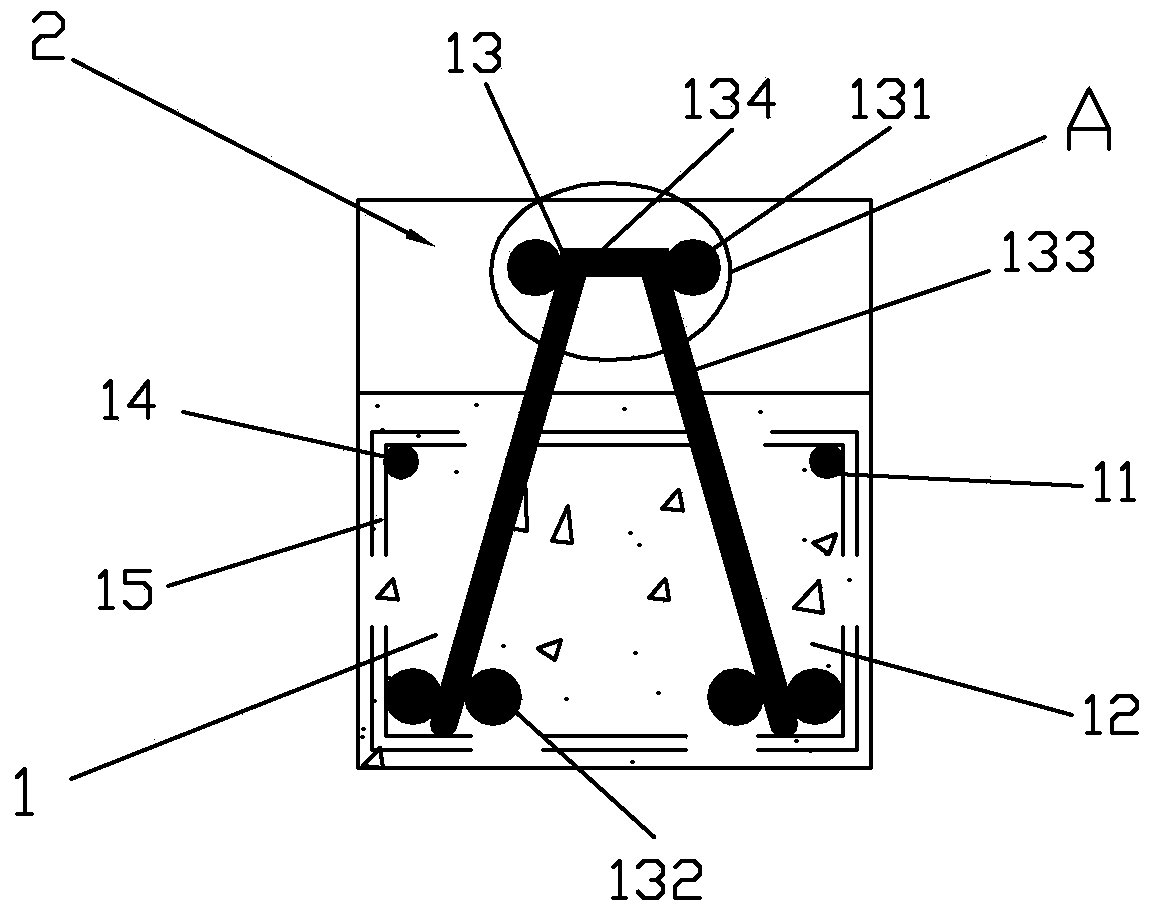

[0044] See figure 1 , figure 2 The truss concrete composite beam of the present invention includes a prefabricated layer 1, which includes a truss steel mesh 11 and a lower concrete layer 12; the truss steel mesh 11 includes a truss 13, erecting steel bars 14 and a number of hoops thereon The rib 15; the truss 13 includes an upper chord 131, a lower chord 132 and a web member 133 connecting the two; the upper chord 131 of the truss is located above the precast concrete 12; the laminated layer 2, which is located in the precast For the cast-in-situ concrete layer on layer 1, in the laminated layer 2, no additional steel bars are provided except for the beams themselves at the support.

[0045] The truss 13 of the present invention is a triangular truss, including three upper chords 131 arranged in parallel and spaced apart, four lower chords 132 arranged in parallel, and two webs 133; the upper and lower chords 131 and 132 are connected by the webs 133; The upper part of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com