Frame structure assembly type vibration reduction component and vibration reduction method

A frame structure, prefabricated technology, used in building components, protective buildings/shelters, earthquake-proof, etc., can solve the problems of poor vibration damping effect, obstruction, adverse effects of controlled structures, etc. The effect of maintenance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The embodiment of the present invention provides an assembleable frame structure based on the vibration of the railway environment, which is installed in a building, which is convenient for installation and maintenance.

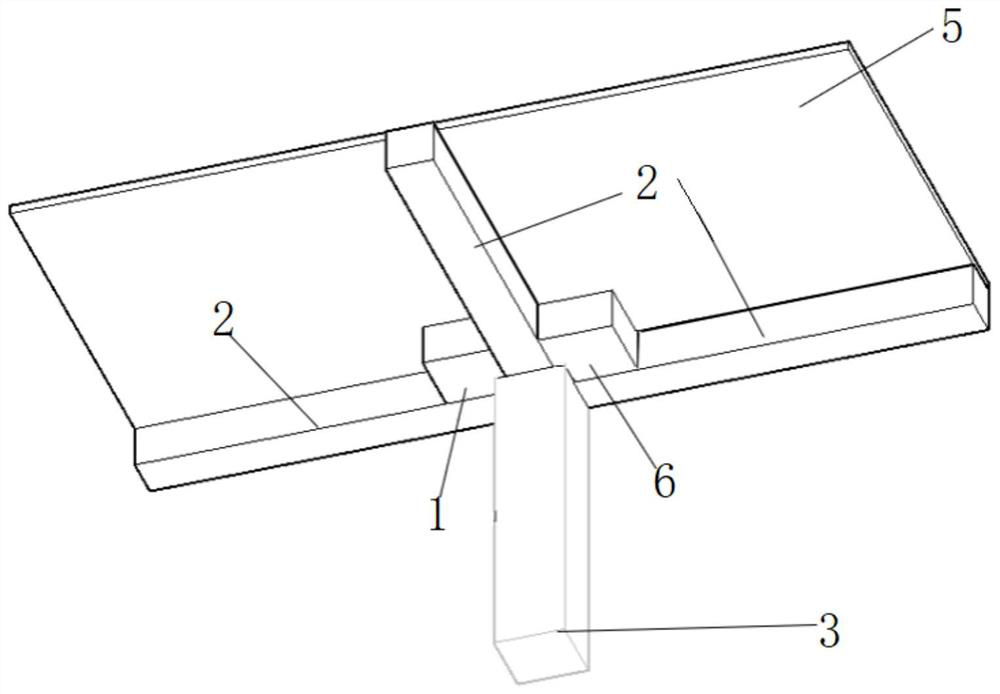

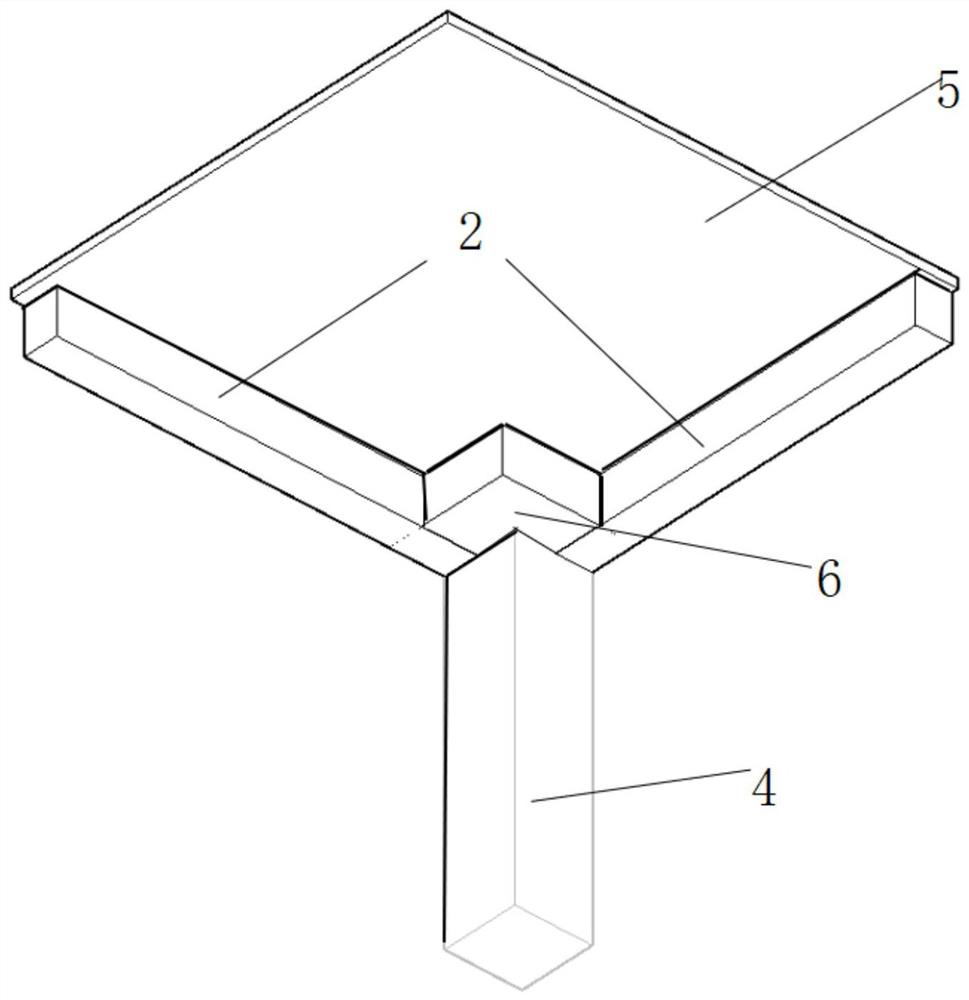

[0039] Such as Figure 1-Figure 2 As shown, the technical solution adopted by the present invention to solve its technical problems is: a frame structure assembly-type damping member for reducing railway environment vibration, including: vibration-damping member assembleable structures 1 and 6, beam 2 , Side column 3, column 4, floor slab 5.

[0040] One side or two sides of the beam 2 are equipped with damping members and can be assembled structures 1 and 6 .

[0041] The vibration-damping component used to reduce the vibration of the railway environment is designed to be a vibration-damping component adjacent to the gap between the beam-column nodes of the railway line frame structure.

[0042] The damping member provided by the embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com