Method for sticking carbon fiber plates through prestress

A technology for pasting carbon fiber and carbon fiber sheets, which is used in bridge maintenance, bridge erection/assembly, and bridge reinforcement. Small headroom, reduced deflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0023] Carbon fiber sheet has excellent performance, so it is widely used in the reinforcement and restoration of bridges, buildings, tunnels, culverts and other various concrete structures. The reinforcement method of sticking carbon fiber sheets to the surface of the structure or component to form a composite body is especially suitable for the repair project of beam bridges (it is the preferred construction method when the construction height is limited), not only the construction is relatively simple, but also the reinforcement effect is remarkable , can greatly improve the bearing capacity and durability of the girder bridge.

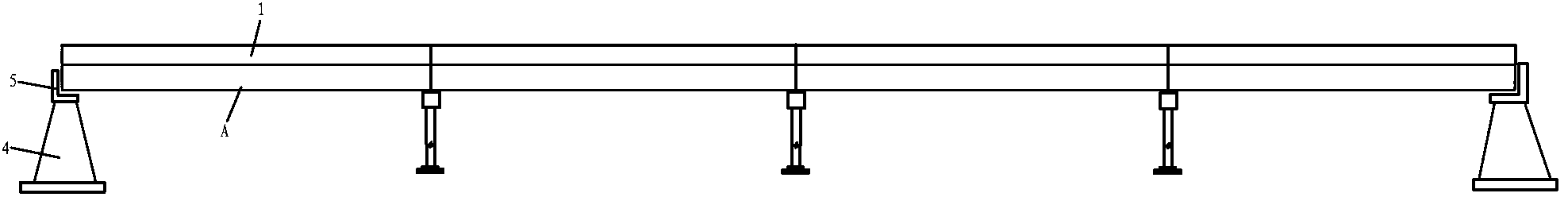

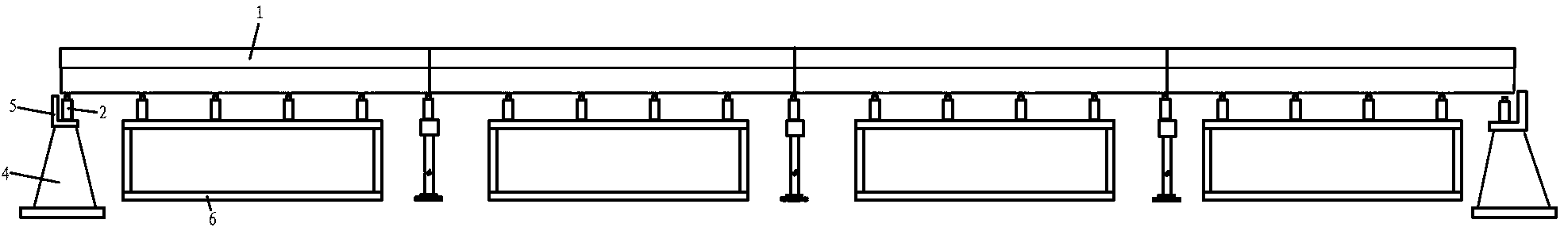

[0024] Such as figure 1 As shown, the existing bridge generally includes several pillars 4, a cover beam 5 fixed on the top of the pillar, and several beam plates 1 succes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com