Gypsum sound insulation system for floor sound insulation and application of gypsum sound insulation system

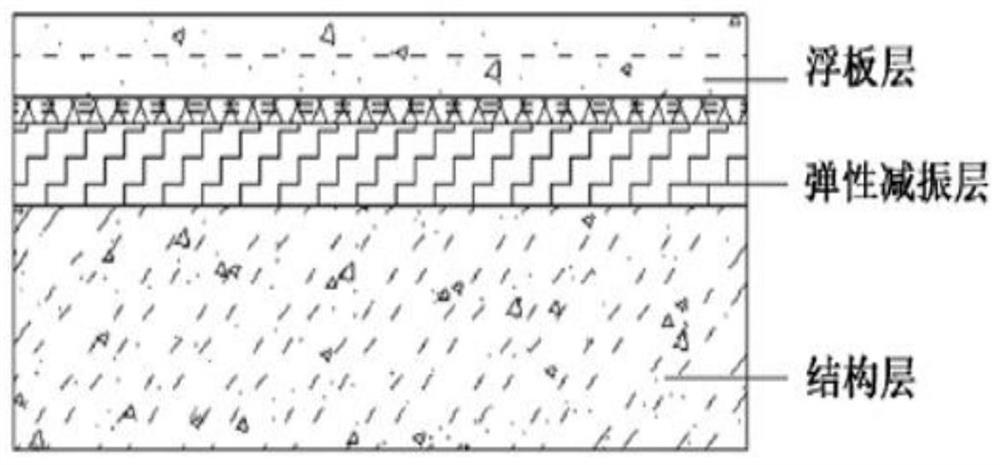

A technology of sound insulation and gypsum, applied in the direction of floor, sound insulation, insulation layer, etc., can solve the problems of reduced room height, low strength, and complicated material detection, so as to reduce room clearance, reduce project cost, and reduce construction procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

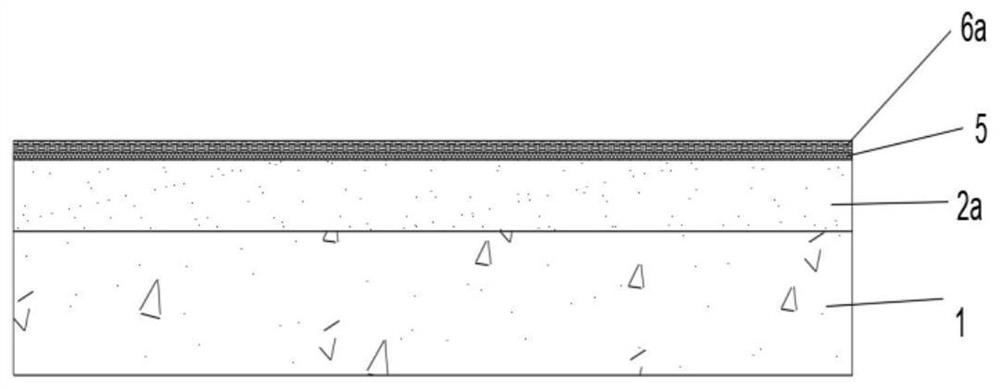

[0053] A gypsum mortar sound insulation system disclosed in this embodiment is composed of a gypsum self-leveling mortar surface layer and a gypsum self-leveling mortar cushion. The 28d dry compressive strength of the layer mortar is 18.3MPa, and the thickness is 10mm. The decorative layer is an 8mm thick ceramic tile decorative layer, pasted with a 5mm thick C1 type ceramic tile adhesive. See the structure diagram Figure 5 .

Embodiment 2

[0055] A gypsum mortar sound insulation system disclosed in this embodiment is composed of a gypsum self-leveling mortar surface layer and a gypsum self-leveling mortar cushion. The 28d dry compressive strength of the layer mortar is 8.2MPa, and the thickness is 15mm. The decorative layer is an 8mm thick ceramic tile decorative layer, pasted with a 5mm thick C1 type ceramic tile adhesive. See the structure diagram Figure 5 .

Embodiment 3

[0057] A gypsum mortar sound insulation system disclosed in this embodiment is composed of a gypsum self-leveling mortar surface layer and a gypsum lightweight mortar cushion. The 28d absolute dry compressive strength of the mortar layer is 4.5MPa, and the thickness is 22mm. The decorative layer is an 8mm thick ceramic tile decorative layer, pasted with a 5mm thick C1 type ceramic tile adhesive. See the structure diagram Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com