Formwork-free ultra-thick floor and construction method thereof

A construction method and formwork-free technology, which is applied in the direction of formwork/formwork/work frame, floor slab, building components, etc., can solve the problems of inability to set up a support frame, unable to carry out formwork or formwork removal, etc., so as to improve the bearing capacity. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

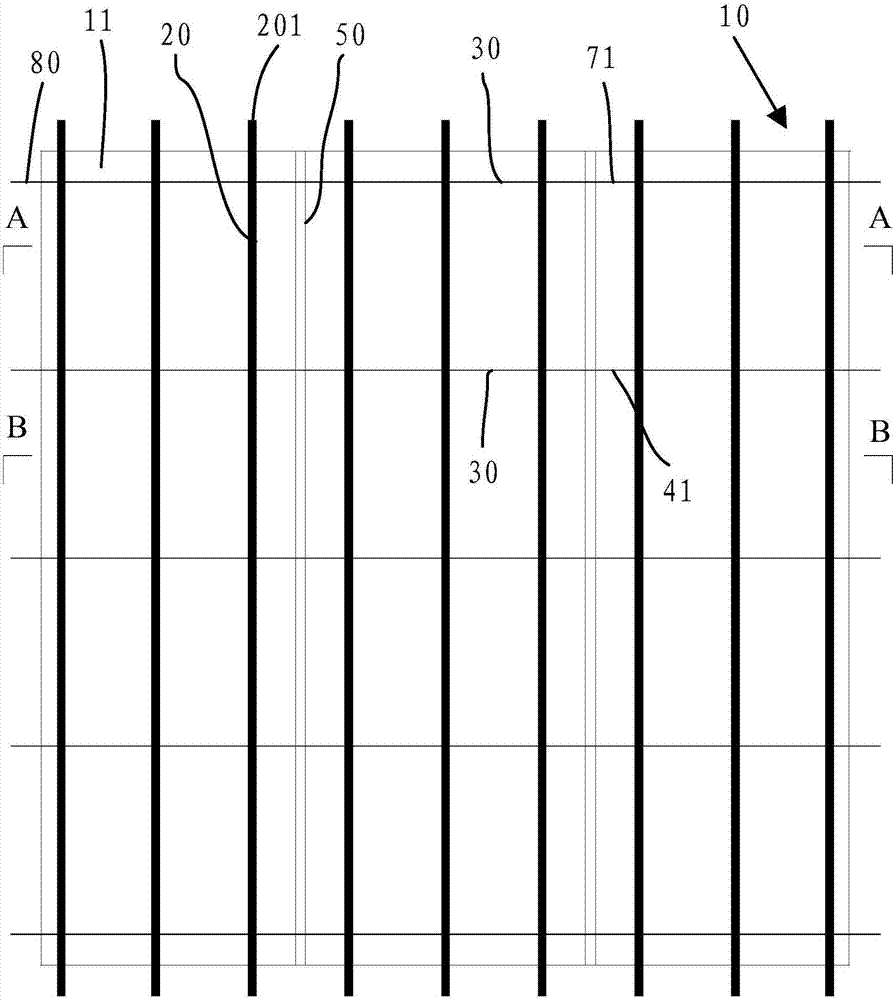

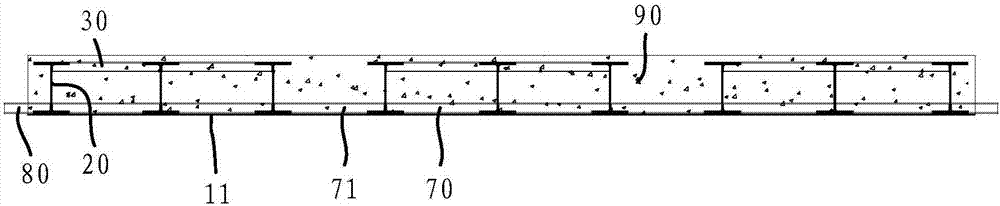

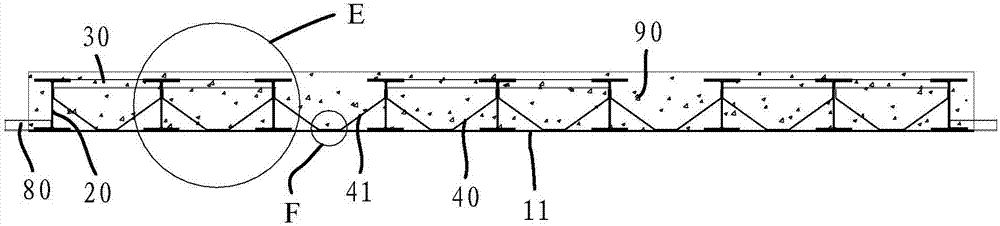

[0039] like Figure 1 to Figure 5 Shown is a schematic diagram of the first preferred embodiment of the present invention, as Figure 6 to Figure 9 It is a schematic diagram of the second preferred embodiment of the present invention. The first preferred embodiment of the present invention is a formwork-free ultra-thick floor slab with one-way force, and the second preferred embodiment of the present invention is a formwork-free ultra-thick floor with two-way force.

[0040] like Figure 1 to Figure 3 , Figure 6 to Figure 8 , The formwork-free ultra-thick floor slab of the present invention has a base plate 10 composed of a plurality of steel plates 11 spliced together. Preferably, the steel plates 11 are galvanized steel plates. A plurality of profiled steels 20 arranged in parallel are welded and fixed at intervals on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com