Building combined type foundation, collar beam and combined frame composed of foundation and collar beam

A combined foundation and building technology, applied in building construction, infrastructure engineering, construction, etc., can solve the problems of long construction period, large amount of formwork, large amount of wet work, etc., and achieve great economic and social benefits, Widely popularized and used, the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

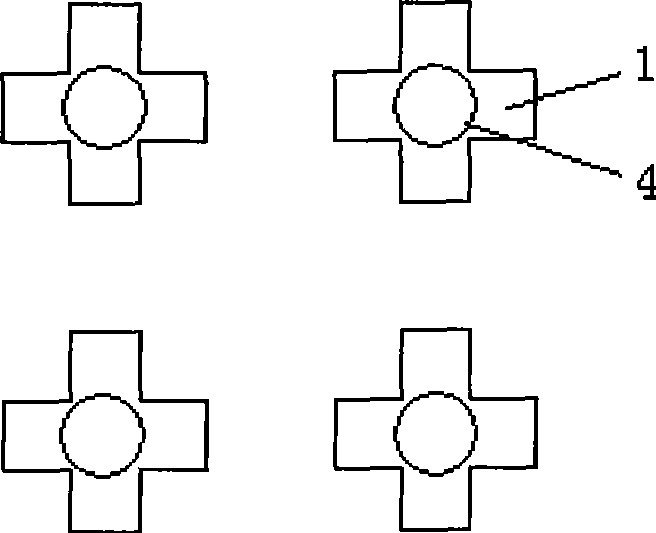

[0021] Such as figure 1 As shown, the combined building foundation of the present invention is composed of four cross-shaped concrete members 1. The cross center of the cross-shaped member 1 is provided with a ring beam, beam and column connection device, and the beam and column connection device is a connection device. The column shoe 4 and the connecting column shoe 4 are round pipes or square pipes made of metal material (a round pipe is selected in this embodiment), and the lower end of the column shoe 4 is inserted into the cross-shaped concrete component when the component is prefabricated. Such as Figure 5 As shown, a connecting hole c41 is provided on the side wall of the connecting column shoe 4, and the connecting hole c41 communicates horizontally.

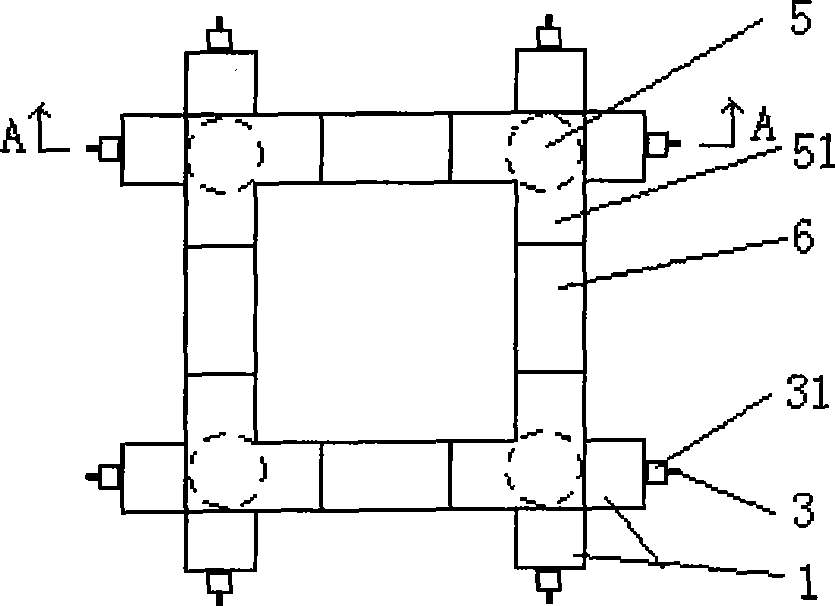

[0022] Such as figure 2 As shown, the building combined ring beam of the present invention is composed of four beams 5 and 6 whose planes are L-shaped upper connecting structures 51; figure 2 , 5 As shown, the connectin...

Embodiment 2

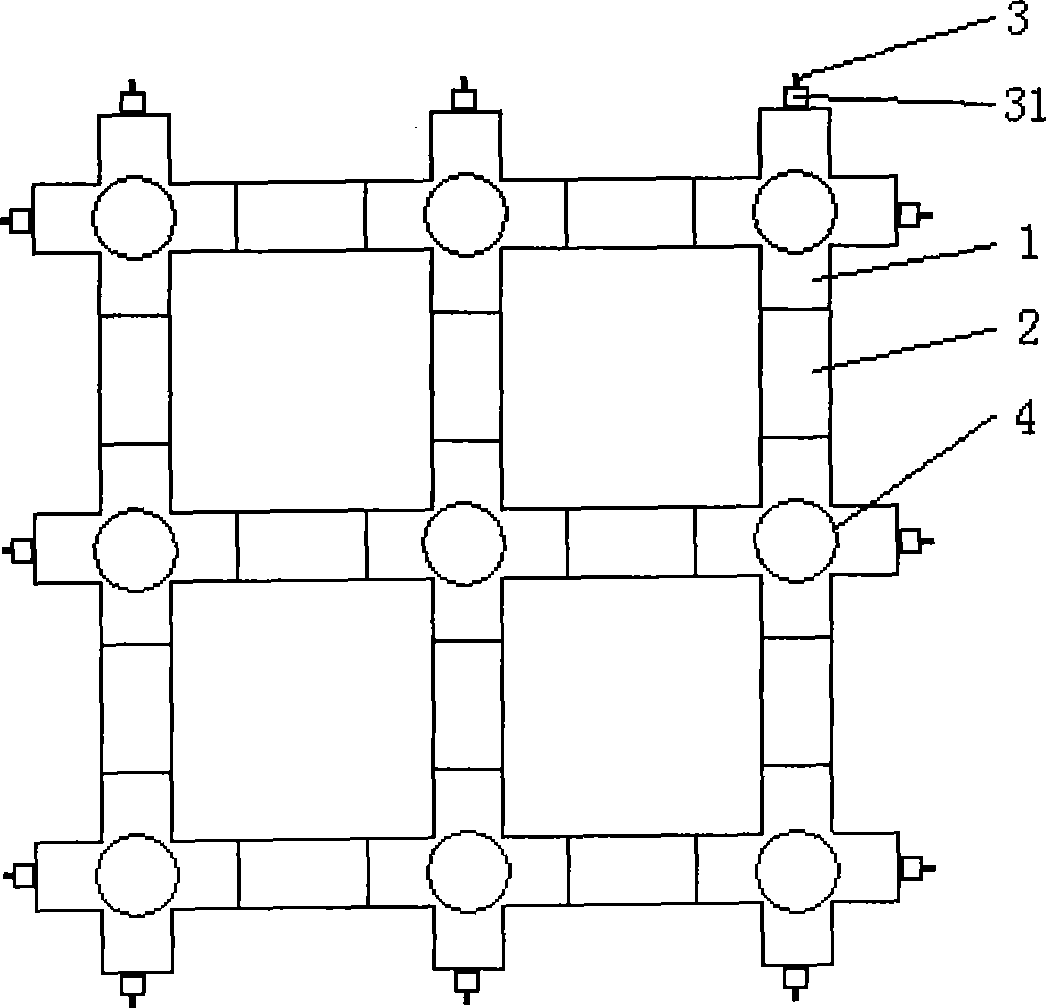

[0024] Such as image 3 As shown, the combined building foundation of the present invention is composed of nine cross-shaped concrete members 1 and a line-shaped member 2; image 3 , 6 As shown, the cross-shaped member 1 is provided with a through connecting hole a11 consistent with its cross, and the in-line member 2 is provided with a through connecting hole b22 that is parallel to the in-line shape and matched with the connecting hole a11, and the connecting object 3 passes through The connecting holes a11 and b22 are connected and fixed with a fastening head 31. Such as Figure 6 As shown, the joint end surface of the cross-shaped member 1 and the in-line member 2 is provided with a matching concave-convex surface, and the matching concave-convex surface is covered with a metal concave-convex part, and the metal concave-convex part and The anastomotic surface of the cross-shaped member 1, the in-line member 2 is provided with paws, and the paws of the concave and convex parts a...

Embodiment 3

[0026] Such as Figure 4 As shown, the building combined ring beam of the present invention is composed of nine upper connecting structures 51 with beams 5 and 6 whose planes are L-shaped, in-line, and cross-shaped, respectively; Figure 4 , 6 As shown, the connecting hole d52 is arranged parallel to the plane L-shaped, or in-line, or cross-shaped axis of the connecting structure 51, the beam 6 is provided with a matching connecting hole g61, and the connecting object 3 passes through the connecting holes d52, g61 for fastening Head 31 is connected and fixed; such as Figure 6 As shown, the beam column 5 is provided with a through connecting hole e53 parallel to the axis, the lower end surface of the beam column 5 is provided with a groove 55, the connecting hole e53 is connected to the groove 55, and the connecting object 3 is recessed from the lower end surface of the beam column 5. The groove 55 penetrates into the connecting hole e53 until it passes through the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com