Spliced joint of prefabricated concrete shear walls and construction method thereof

A technology of prefabricated concrete and concrete walls, applied to walls, building components, buildings, etc., can solve the problems of large steel consumption and difficult construction of prefabricated steel plate composite shear walls, so as to improve construction speed and construction accuracy, reduce The effect of formwork dosage, improvement of assembly rate and construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

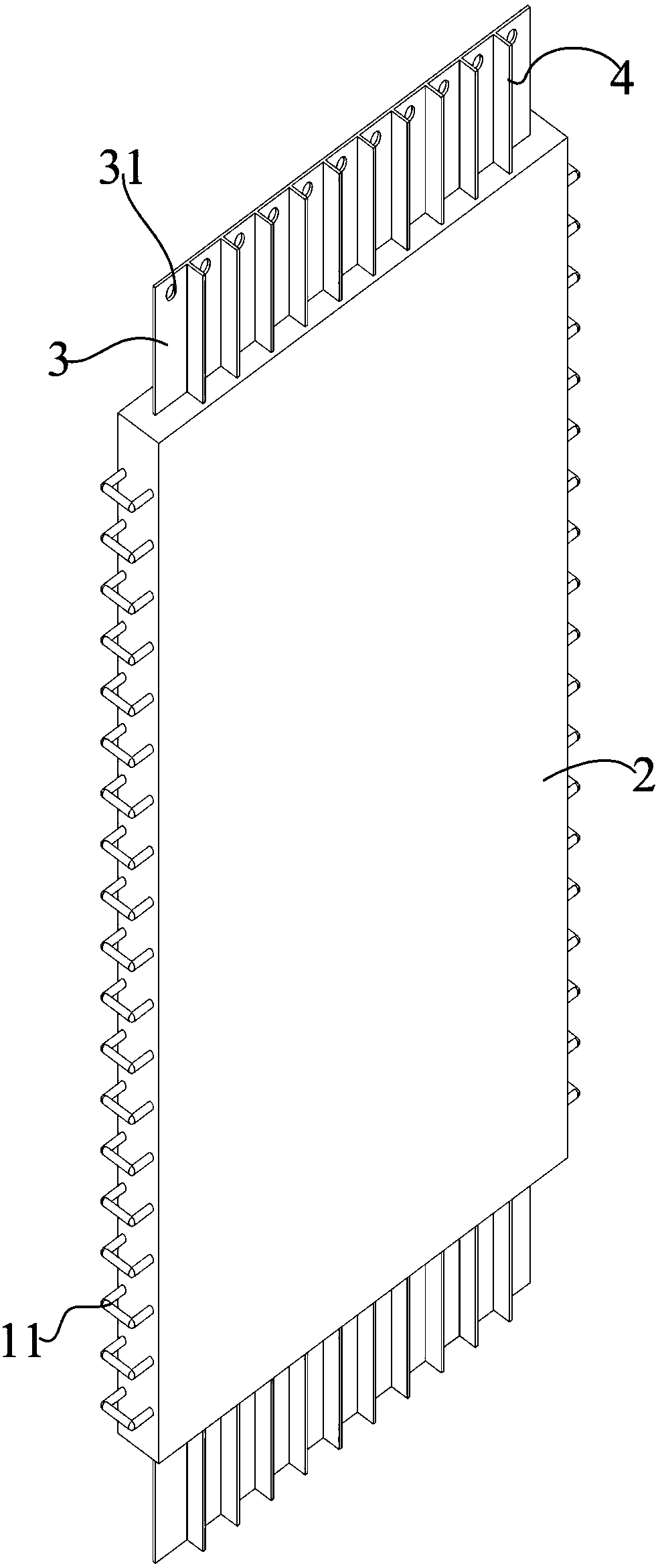

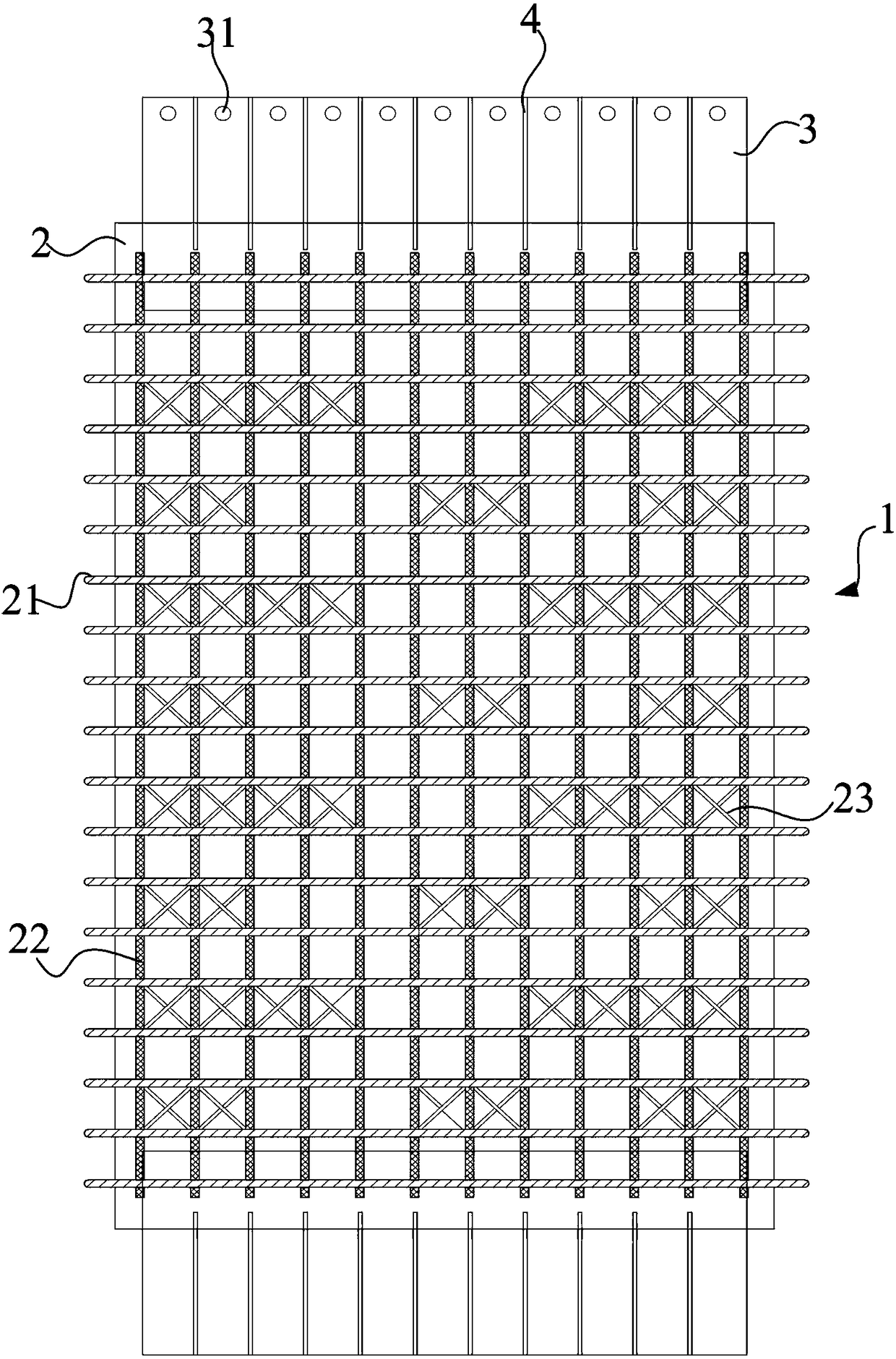

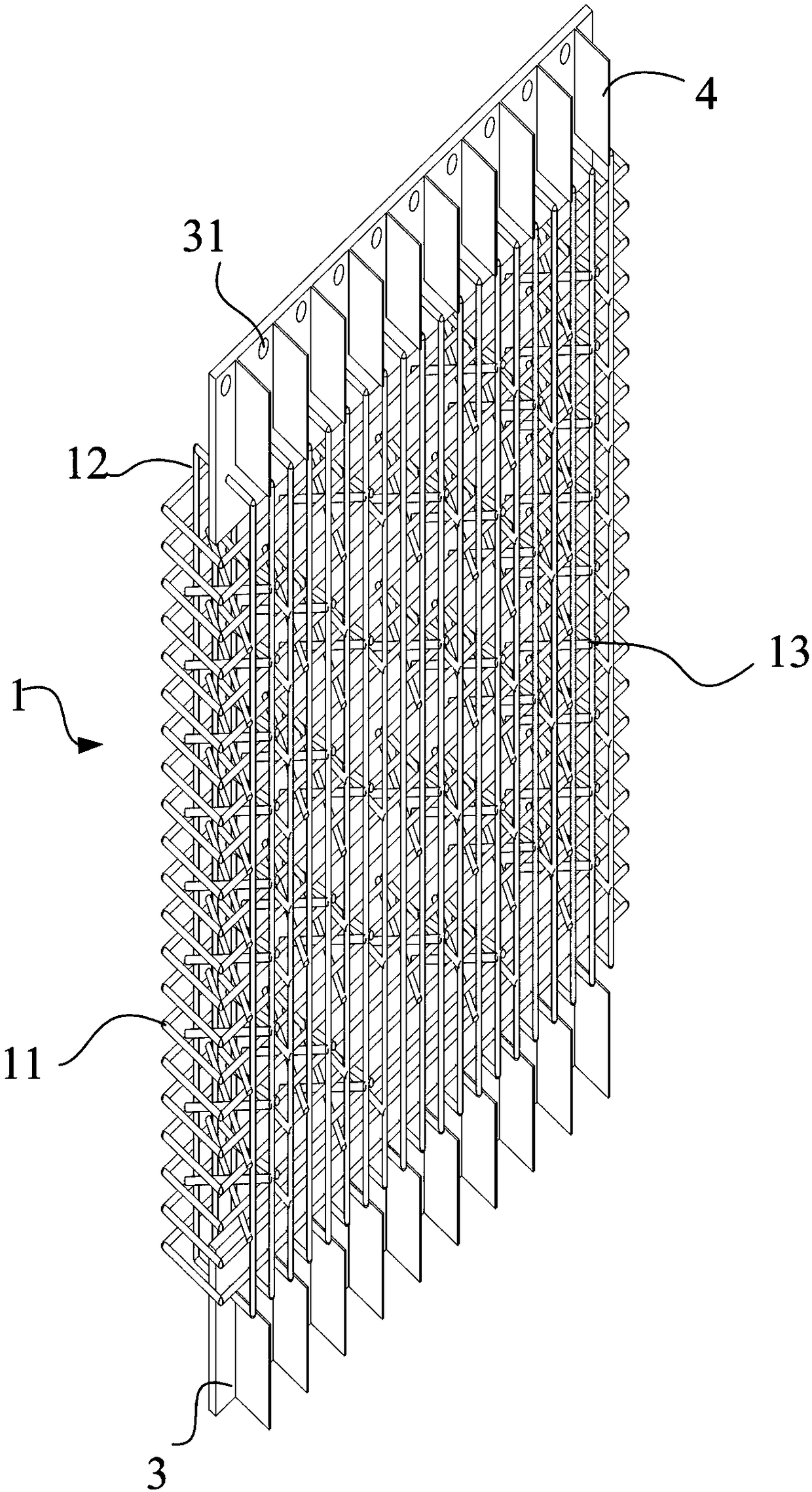

[0026] Example 1, such as figure 1 , figure 2 , image 3 As shown, this embodiment aims to provide a splicing joint of precast concrete shear walls that is convenient for on-site connection. Therefore, the splicing joints of precast concrete shear walls provided by this embodiment include precast concrete walls and The double-layer reinforced mesh inside the wall, the size of the prefabricated concrete wall is the same as the existing shear wall, generally the height of the first floor. The double-layer steel mesh is the steel mesh set at the front and back, and it is also composed of horizontal steel bars set horizontally and vertical steel bars set vertically to form a grid mesh structure.

[0027] Different from the existing integrated steel plate, the key improvement of this embodiment is that the upper and lower ends of the precast concrete wall are pre-embedded with spliced steel plates for connecting the upper and lower precast concrete shear walls, and the spliced...

Embodiment 2

[0036] Embodiment 2, this embodiment provides the construction method of the splicing joint of the precast concrete shear wall provided by embodiment 1

[0037] Firstly, the splicing steel plate at the lower part of the splicing node of a prefabricated precast concrete shear wall is fixed to the constructed lower wall by welding or bolting (the lower wall can be the foundation wall or the first floor that has been implemented. The splicing node of the prefabricated concrete shear wall, the foundation wall is the foundation poured at the construction site, and the splicing steel plates required for the connection are pre-embedded on the foundation), the welding and bolt fixing methods are mainly splicing the upper and lower pieces Adding a steel plate to one side of the steel plate to connect the upper and lower steel plates is a common method in existing prefabricated buildings, so it will not be described in detail in this embodiment.

[0038] Then start from the splicing nod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com