Fabricated integral type concrete pool

A concrete and integral technology, applied in protection devices, water conservancy projects, underwater structures, etc., can solve the problems of high rental cost, high transportation cost and small size of large-scale construction equipment, avoiding cracks at joints, The effect of less wet work and high component reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

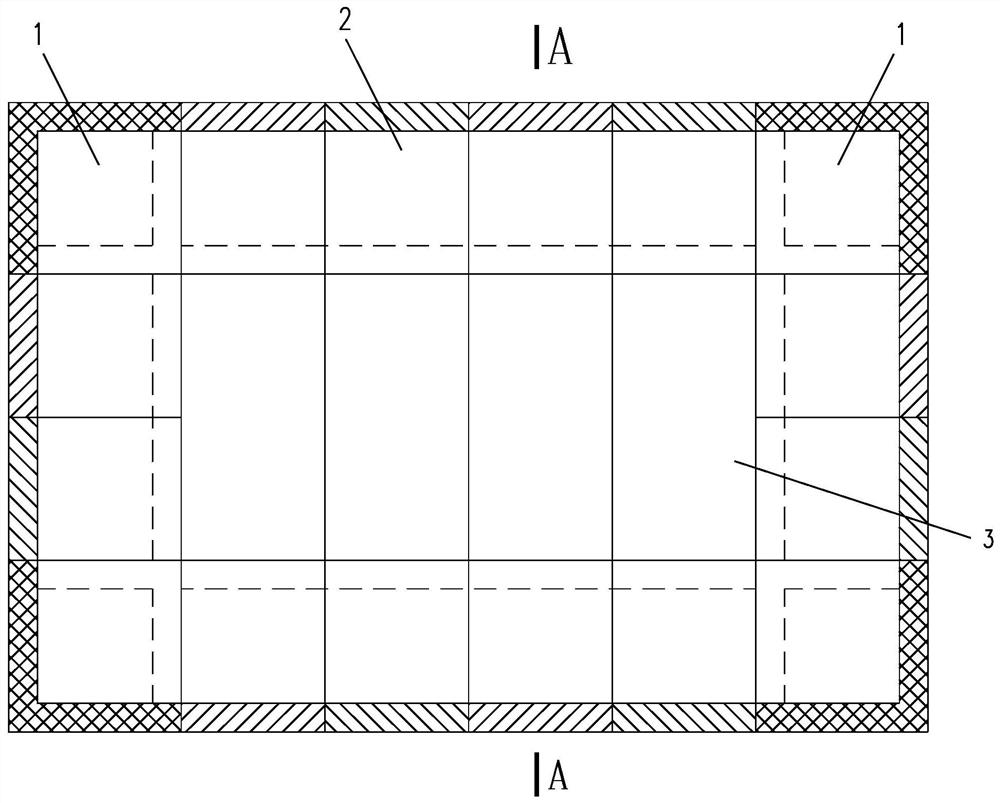

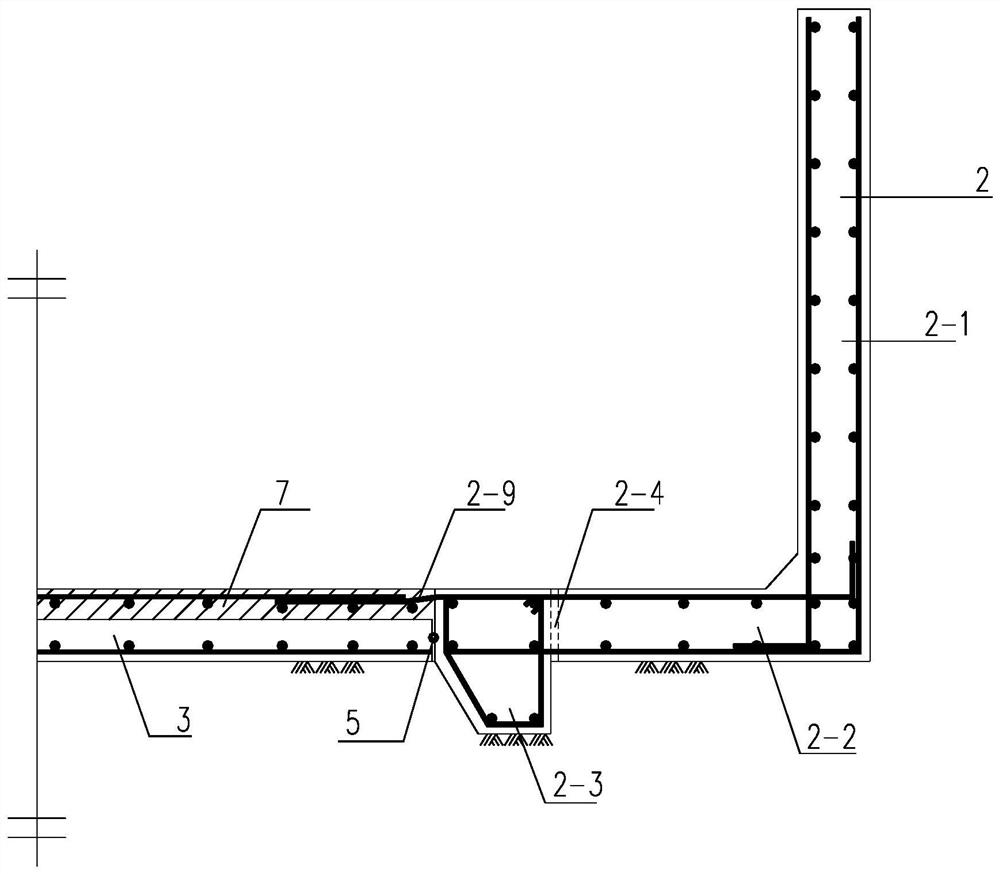

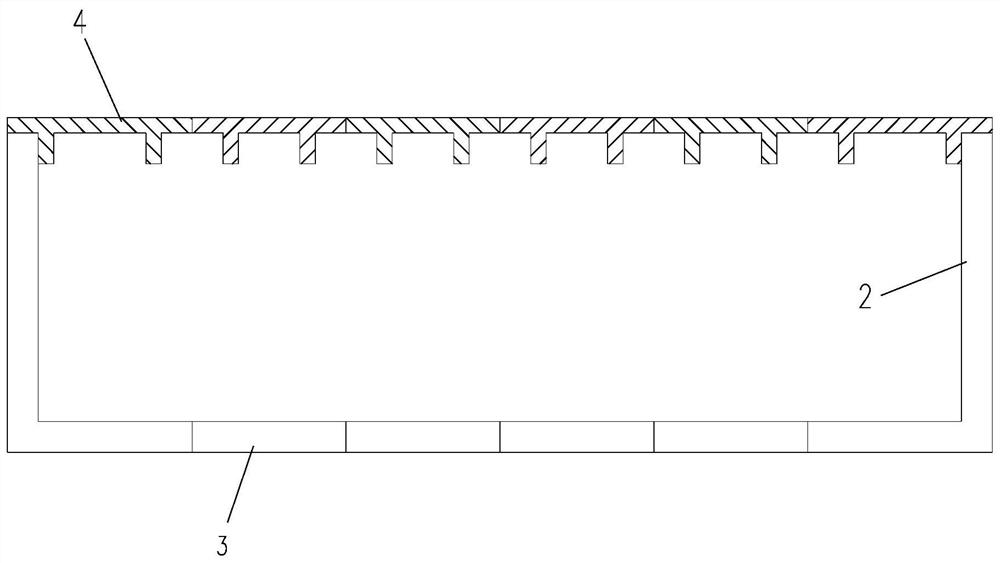

[0029] Such as Figure 1-14 Shown is a schematic diagram of an embodiment of an assembled integral concrete pool provided by the present invention.

[0030] An assembled integral concrete pool, which is spliced by a prefabricated corner wall panel 1 and a prefabricated corner wall panel 2, the prefabricated corner wall panel 1 is separately arranged at the corner, and the prefabricated corner wall panel 2 is spliced between adjacent prefabricated corner wall panels 1 ;

[0031] The prefabricated wall panel 2 includes a vertical side wall panel A2-1 and a horizontal bottom plate A2-2, and the lower side of the horizontal bottom plate A2-2 is provided with an anchoring flange A2-3 corresponding to the vertical side wall panel A2-1 ; The vertical side wall panel A2-1, the horizontal bottom panel A2-2 and the anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com