Deep water circular floating artificial port

An artificial port and ring-shaped technology, applied in water conservancy projects, sea area projects, floating buildings, etc., can solve the problem of low material transfer efficiency, wave dissipation facilities that do not have the function of sheltering ships from wind, and box-type super-large floating structures. Poor performance and other issues, to achieve the effect of high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

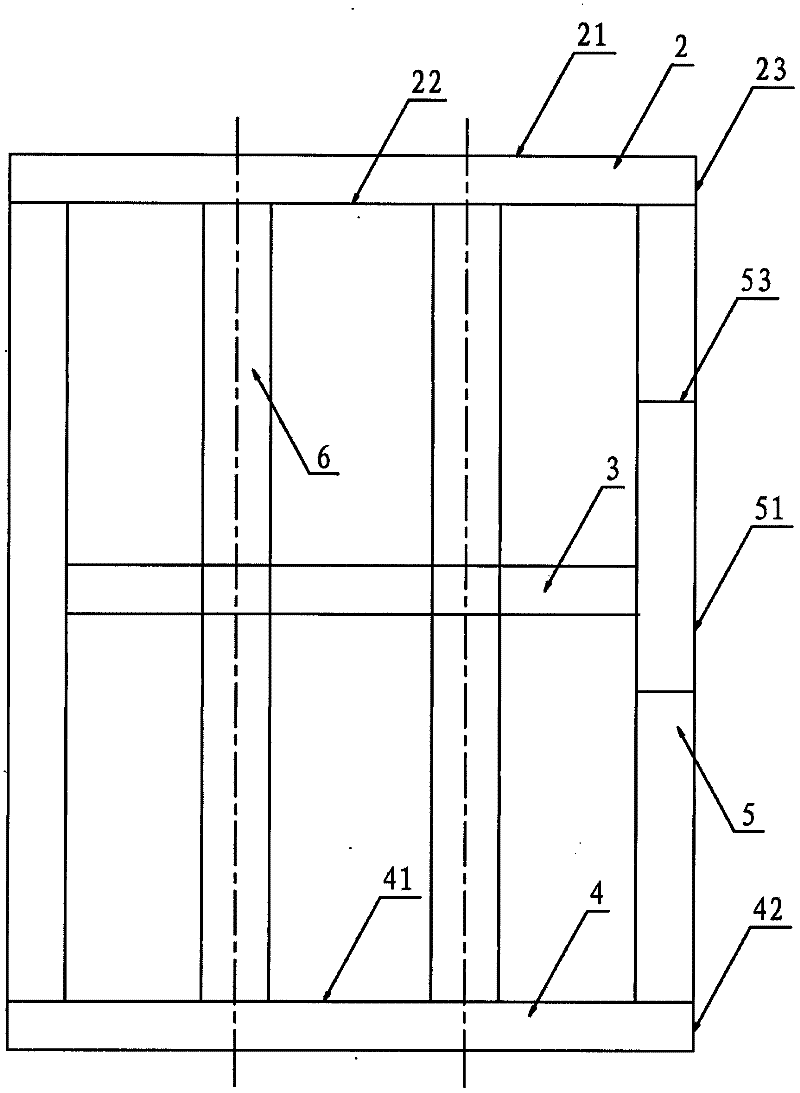

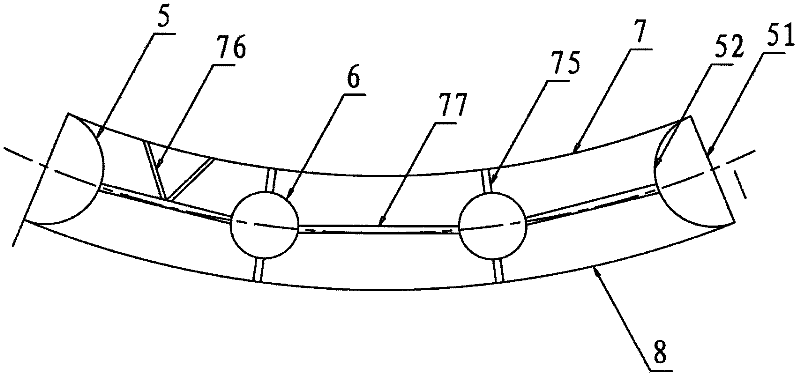

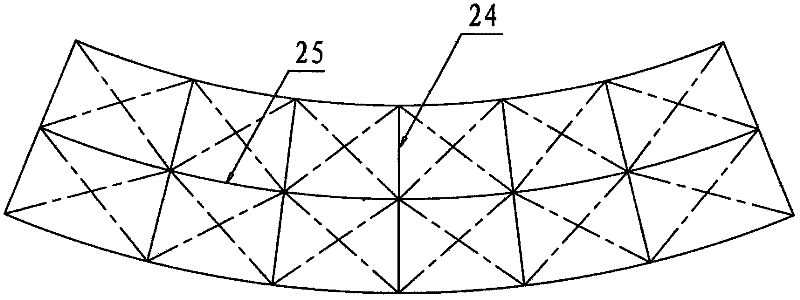

[0028] Such as Figure 1-Figure 6 As shown, the present invention includes: a single module 1, an upper pontoon 2, an intermediate pontoon 3, a lower pontoon 4, a side column 5, a center column 6, an inner wave dissipation wall 7, an outer wave dissipation wall 8, and a fixed connection Part 9, detachable connector 10, inboard berthing device 11, outboard berthing device 12, living building 13, helideck 14, crane 15 and winch 16 are made up of 16 parts altogether.

[0029] Wherein, there are several single modules 1, eight in this embodiment. Several single modules 1 are connected through fixed connectors 9 to form an arc-shaped module; several arc-shaped modules are connected through detachable connectors 10 to form an annular floating structure that can be opened and closed for ships to enter and exit. Modular structure. The single module 1 includes: several buoyant tanks, and the several buoyant tanks are arranged in layers from top to bottom. layer.

[0030] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com