Fully-prefabricated floor and composite floor composite structure and manufacturing and assembly method

A technology of superimposed floor slabs and combined structures, which is applied in the direction of floor slabs, building components, building structures, etc., to achieve high assembly rate, easy construction quality assurance, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

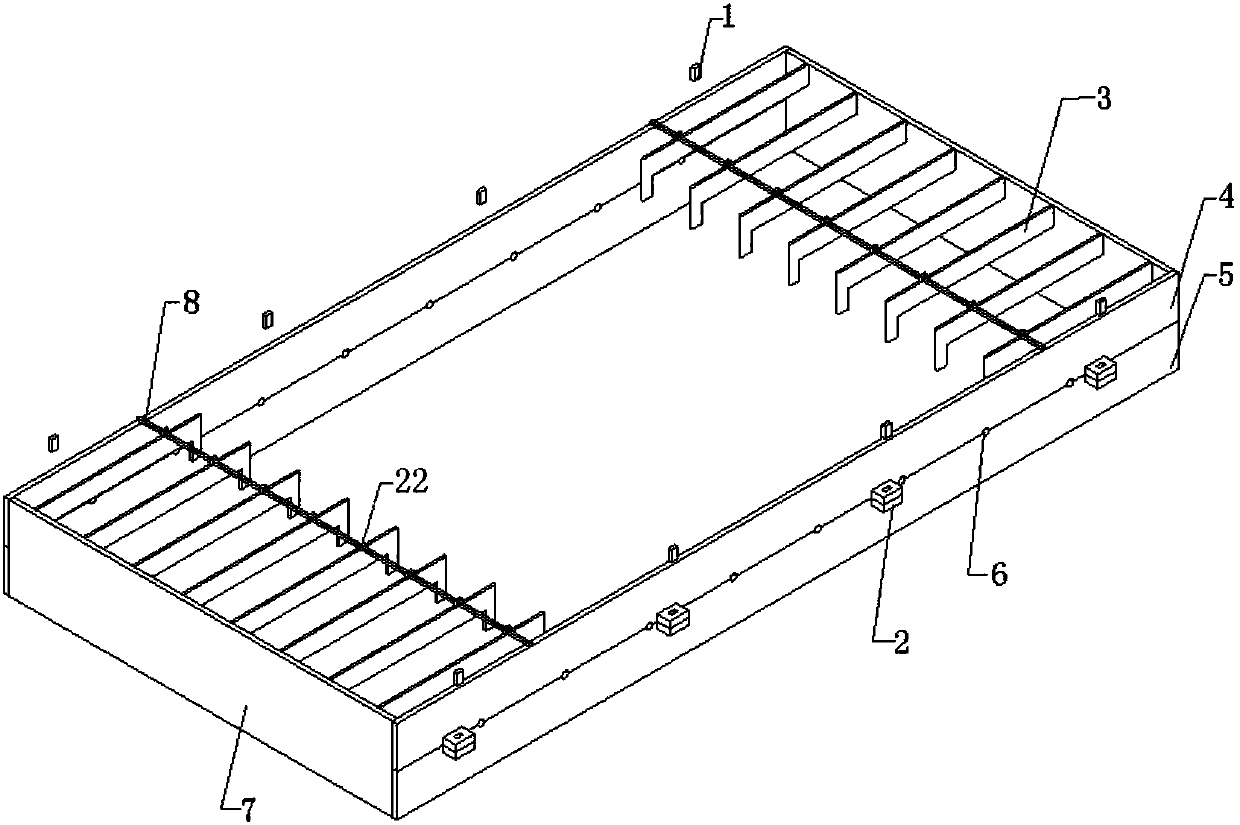

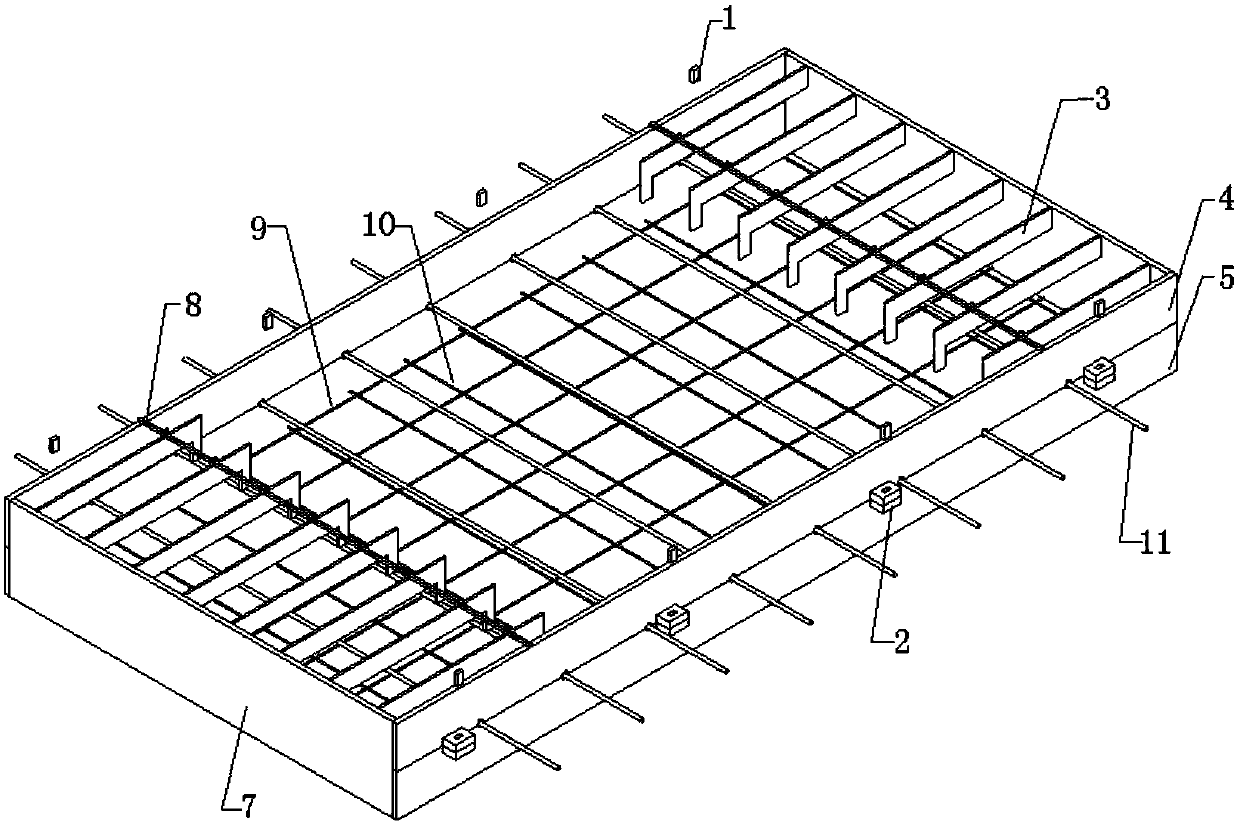

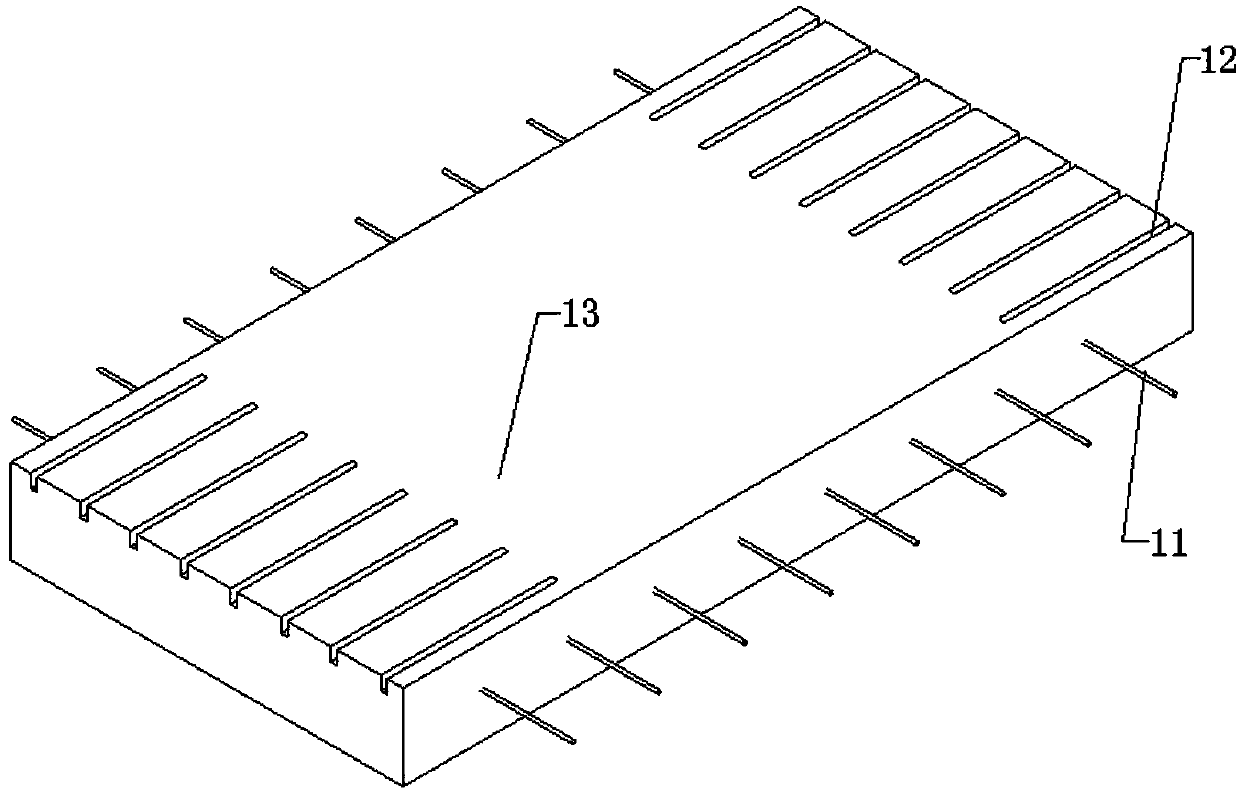

[0038] Such as Figure 1-Figure 12 As shown, the combined structure, manufacturing and assembly methods of the fully prefabricated floor slab and the laminated floor slab of the present invention are as follows:

[0039] 1. The structure and manufacturing method of the fully precast concrete unidirectional slab of the present invention are as follows:

[0040] Such as figure 1 As shown, the formwork of the concrete one-way slab is composed of steel formwork on opposite sides of the steel formwork and steel formwork on opposite ends of the frame. The steel formwork on opposite sides is composed of the upper steel formwork 4 and the lower steel formwork. The upper steel template 4 and the lower steel template 5 are connected into a whole by inserting the connecting steel bolt 1 into the connecting steel ring 2. The steel template on the two sides has a reserved hole 6 at the central axis; located at the end One end of the L-shaped template 3 is welded in the opposite steel template 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com