Prefabricated concrete-filled steel tube overlapped pier

A technology for CFST and CFST columns, applied in bridges, bridge construction, bridge parts, etc., to facilitate positioning and installation, improve transfer ability, and eliminate the need for welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

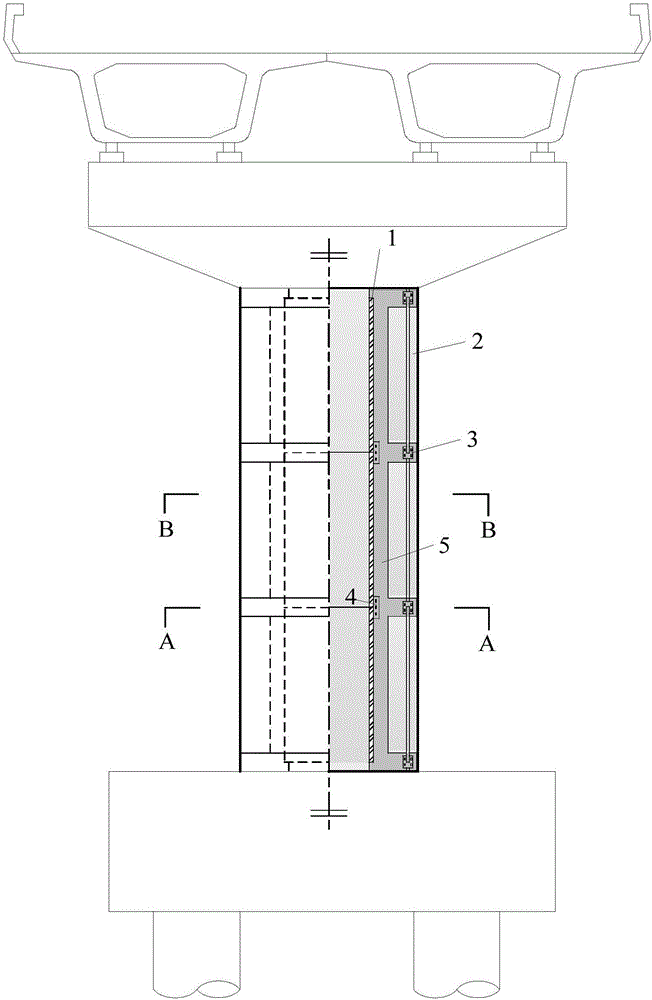

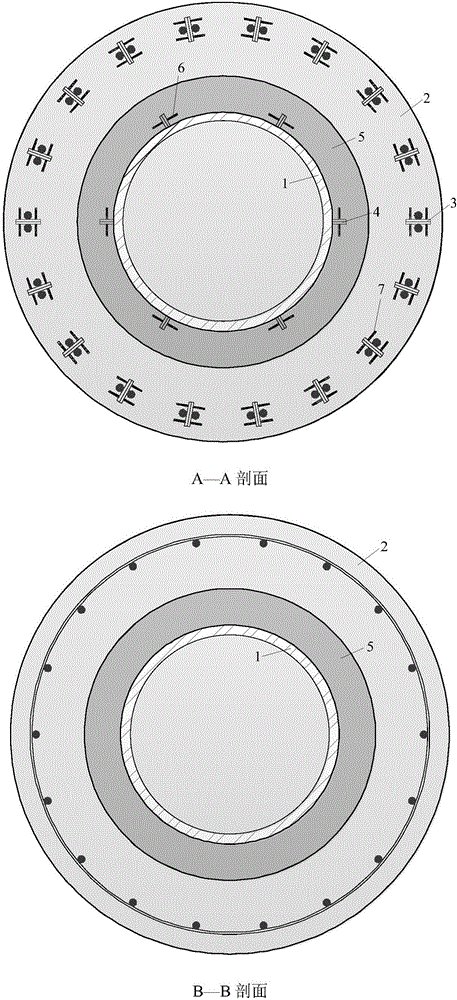

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] As shown in the accompanying drawings, the present invention is a prefabricated steel pipe concrete composite bridge pier, which is connected by prefabricated steel pipe concrete columns, prefabricated reinforced concrete casings, steel bar connectors, steel pipe connectors, short steel bars in steel pipe connectors, and steel bars. It is composed of short steel bars and concrete post-cast strips in the parts. Its assembly procedure is as follows:

[0022] Factory prefabricated:

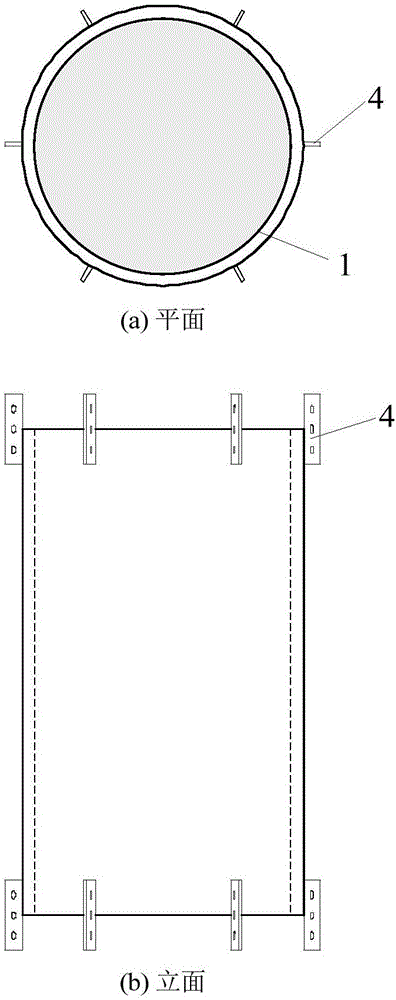

[0023] a. Prefabricate the basic components of the pier in the factory: prefabricated steel tube concrete column 1, prefabricated reinforced concrete casing 2, steel bar connector 3, steel tube connector 4, short steel bars in steel tube connectors 6, short steel bar connectors Rebar 7.

[0024] b. The steel pipe connector 4 is welded to both ends of the steel pipe in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com