Structure of fully prefabricated one-way plate with splicing grooves and manufacturing and assembling method of structure of fully prefabricated one-way plate with splicing grooves

An assembly method and one-way slab technology, applied to floors, building components, manufacturing tools, etc., can solve the problems of poor integrity of fully precast concrete floors, and achieve the effects of easy construction quality assurance, high assembly rate, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

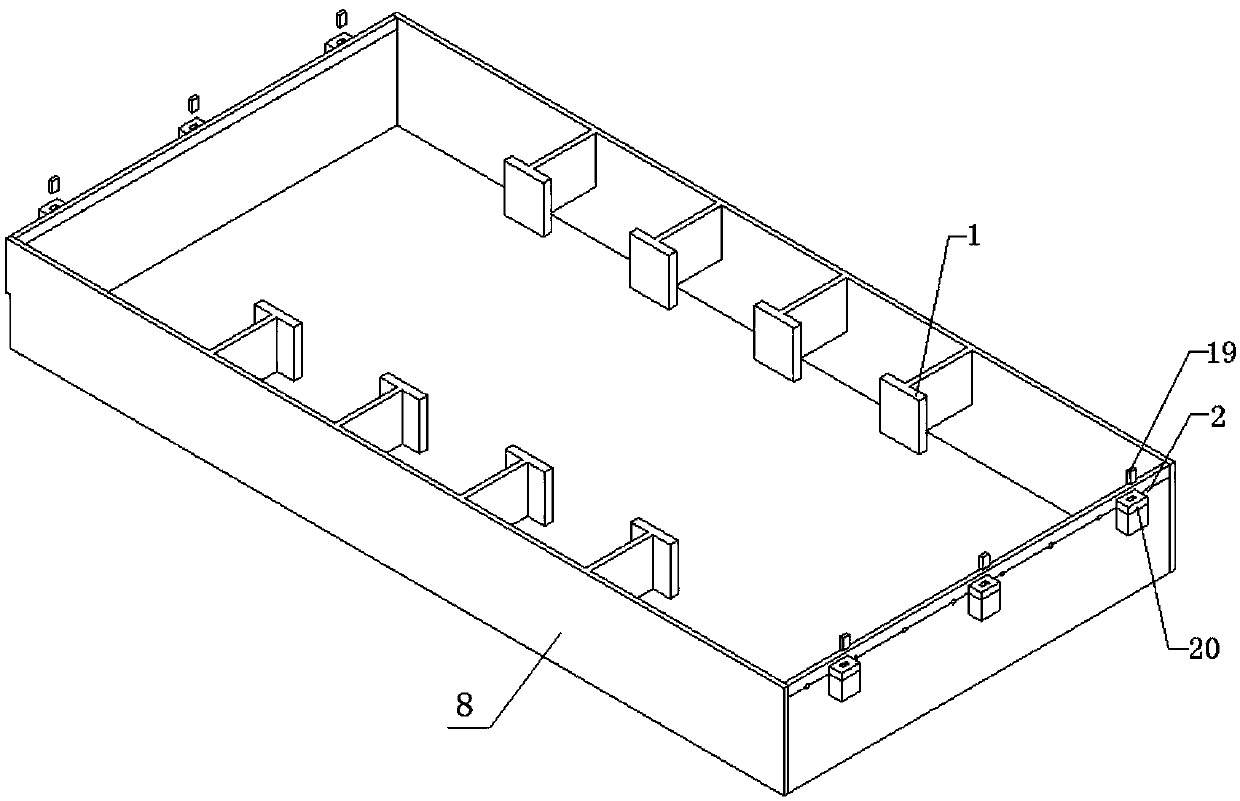

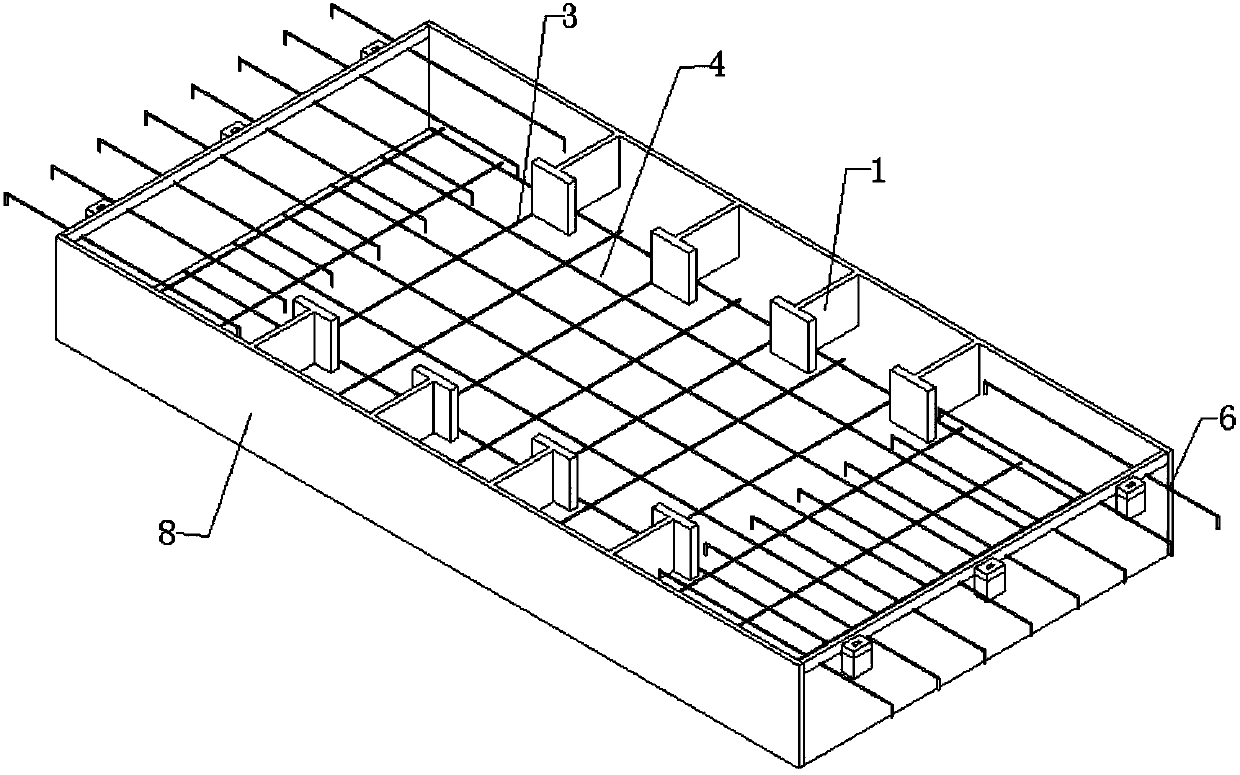

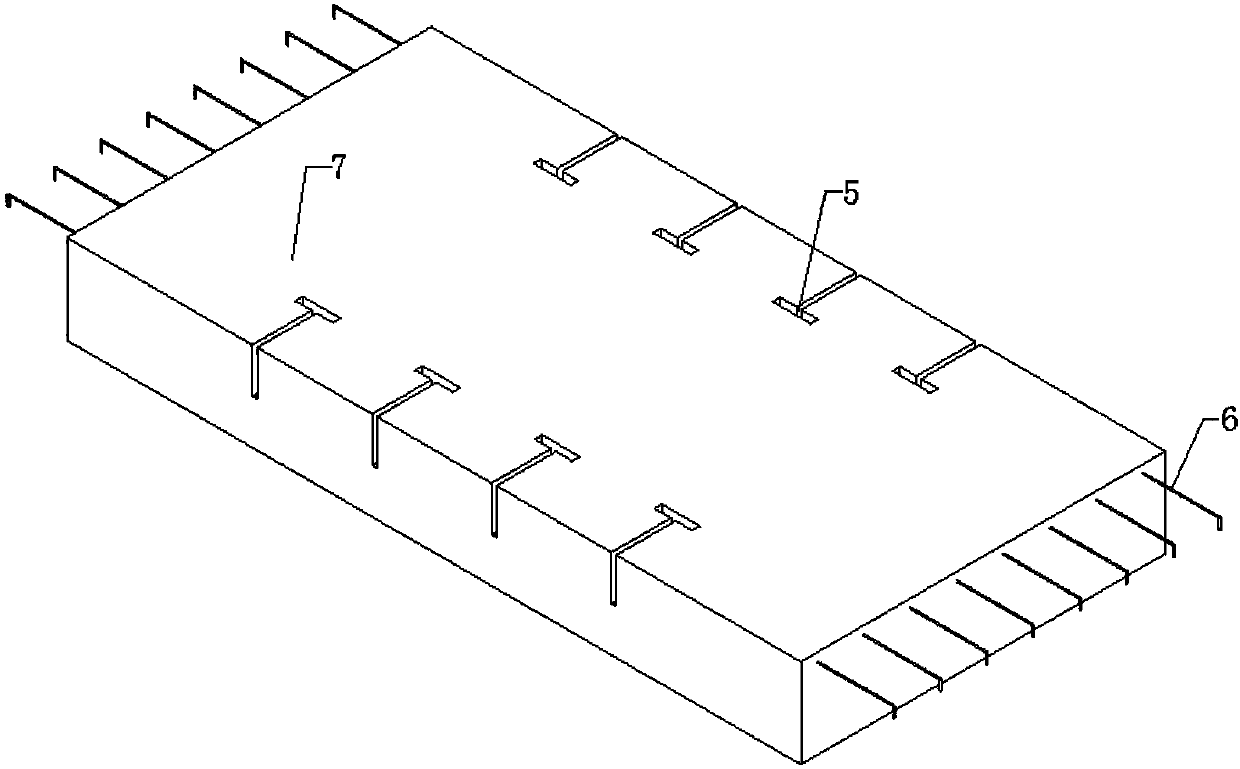

[0043] Such as Figure 1-Figure 15 As shown, the structure, production and assembly methods of the fully prefabricated one-way panel with splicing grooves of the present invention are as follows:

[0044] Such as Figure 1-Figure 2As shown, the formwork structure of the prefabricated concrete one-way slab 7, the four sides of the formwork structure are steel formwork 8, the steel formwork located on the longitudinal sides are respectively composed of upper and lower steel bars, and the negative moment bars 6 pass through vertically. Located between the upper and lower steel bars, there is a reserved hole 2 between the upper and lower steel bars, along the central axis of the negative moment bar 6, through which the fixed steel bars 19 are inserted into the fixed steel rings 20 to connect the upper and lower steel bars , form the steel templates on both sides of the longitudinal direction; the steel templates on both sides of the horizontal direction are respectively a steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com