Improved hidden beam type connection full-prefabricated slab structure and manufacturing and assembling method

An assembly method and prefabricated panel technology, which is applied to floors, building components, manufacturing tools, etc., can solve the problems of weak shear resistance and slow assembly speed, and achieve the effect of simple on-site assembly, high assembly rate, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

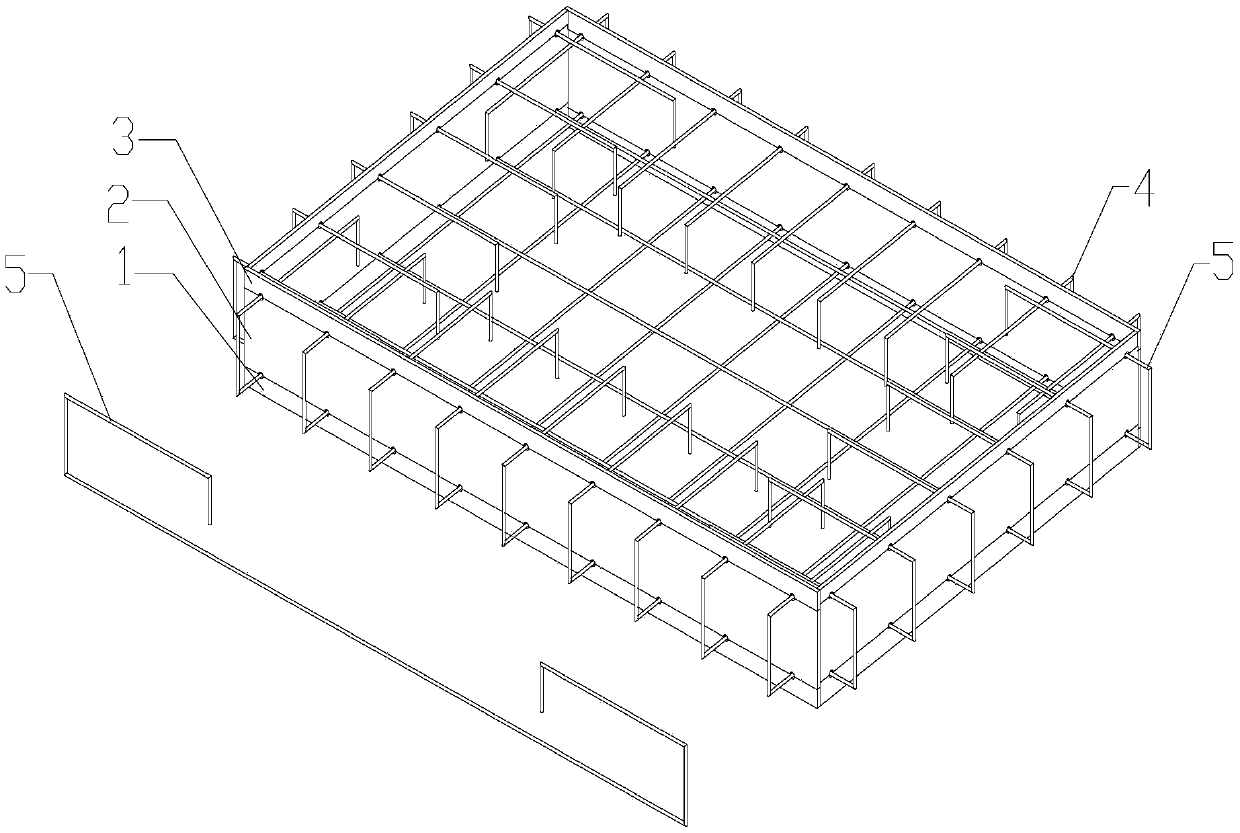

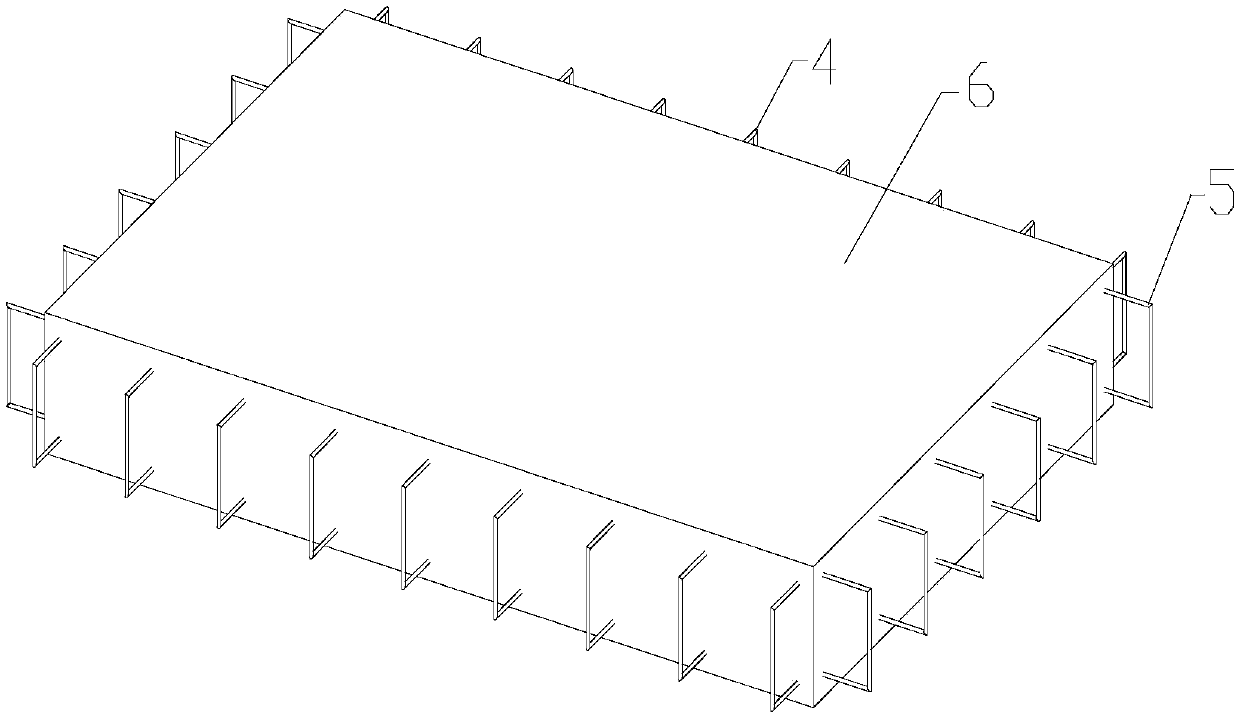

[0024] like Figure 1-Figure 3 As shown, the improved full prefabricated panel structure manufacturing process of the present invention is as follows:

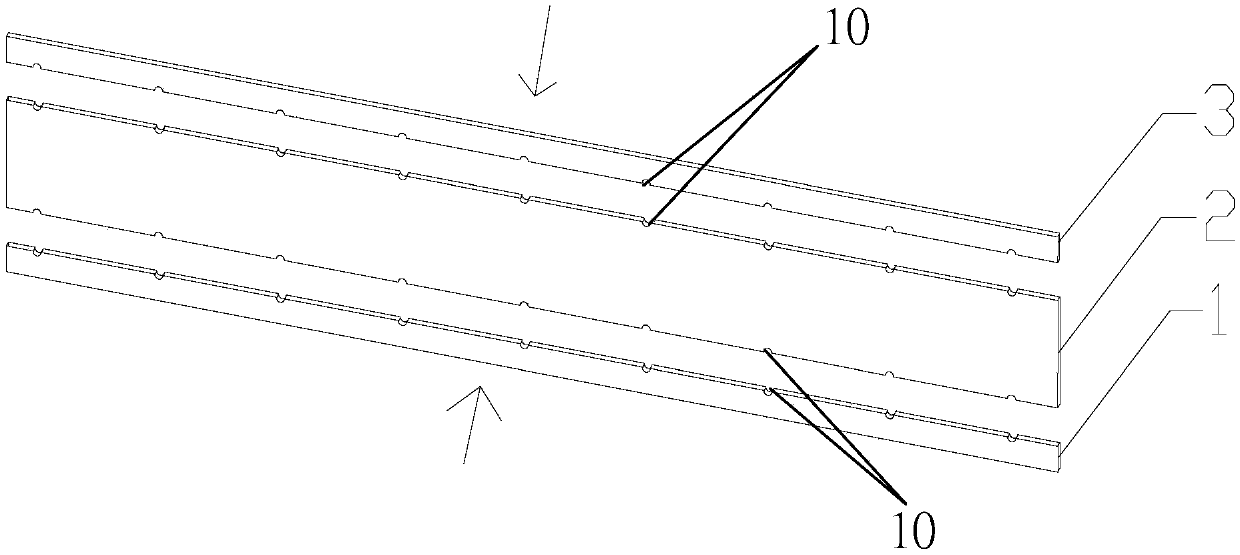

[0025] like Figure 1-Figure 2 As shown, the template adopts a frame surrounded by four spliced steel templates. Each spliced steel template is a spliced steel template composed of an upper template strip 3, a middle template strip 2 and a lower template strip 1. The upper and lower sides of the middle template strip 2 are respectively set. Formwork strip 3, lower formwork strip 1, upper formwork strip 3 and middle formwork strip 2 corresponding surfaces are evenly provided with semicircle holes 10 respectively, lower formwork strip 1 and middle formwork strip 2 corresponding surfaces are evenly provided with semicircle holes 10 respectively, and corresponding The semicircular hole 10 forms a reserved hole. Determine the size and aperture of the upper template strip 3, the middle template strip 2 and the lower template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com