Assembly type concrete truncated pyramid type foundation and column steel connecting structure and assembling method

A technology for connecting structures and concrete, applied in basic structure engineering, structural elements, columns, etc., can solve problems such as slow construction speed, and achieve the effect of improving construction efficiency, saving learning costs, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

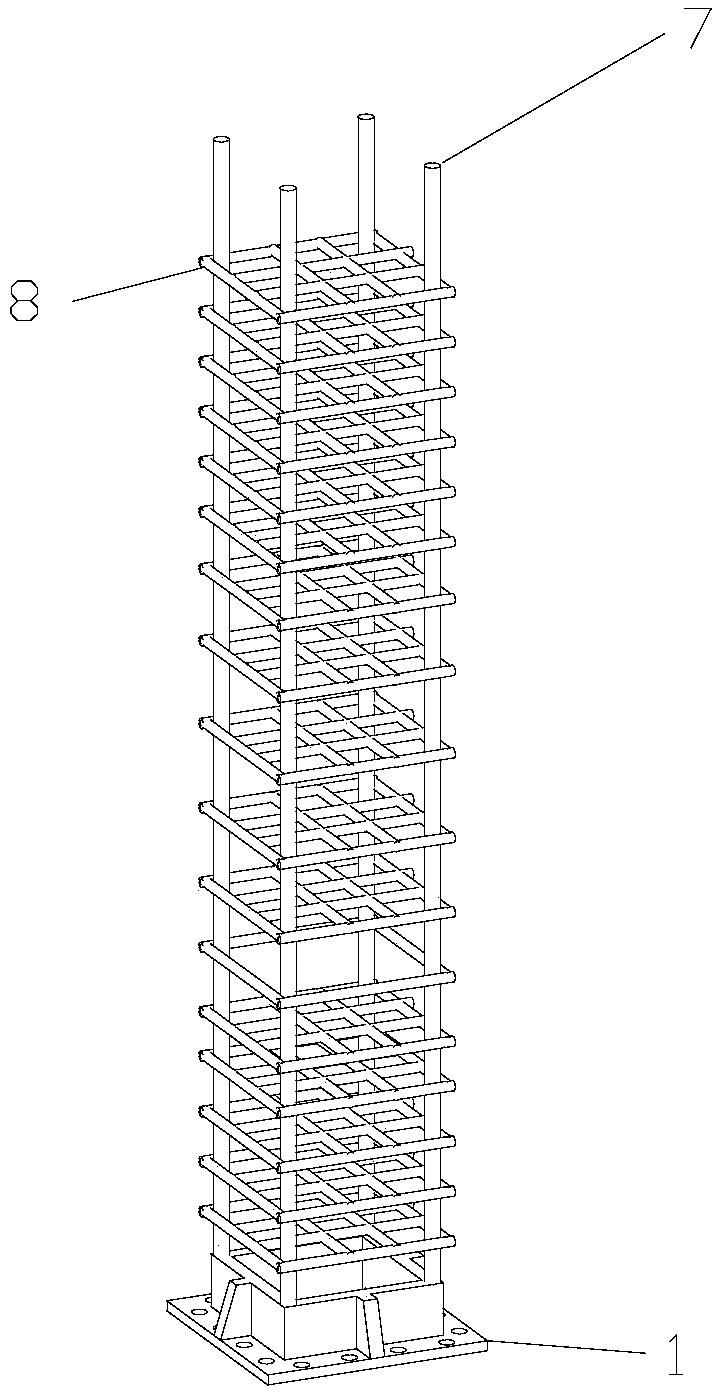

[0037] Such as Figure 1-Figure 11 As shown, the prefabricated concrete truss-shaped foundation and column steel connection structure of the present invention mainly includes prefabricated columns and prefabricated truss-shaped foundations, as follows:

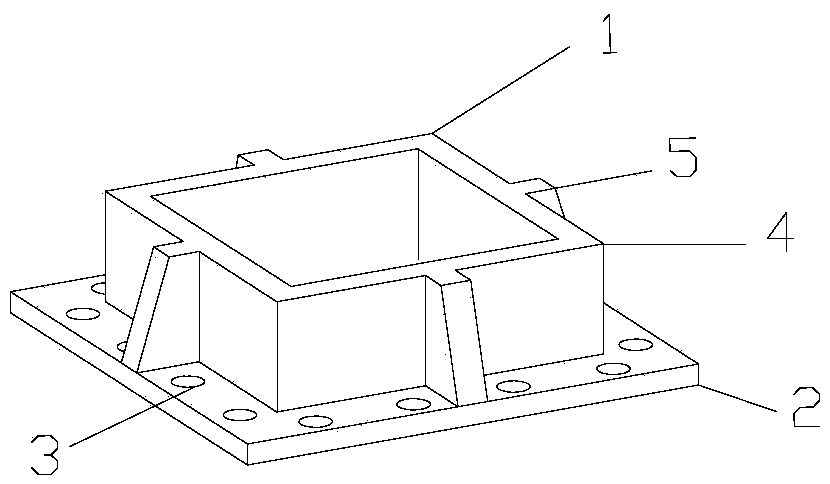

[0038] (1) If figure 1 As shown, the specific structure and manufacturing process of the prefabricated parts under the column are as follows:

[0039] The prefabricated part 1 under the column is welded by a perforated bottom plate 2, four lateral steel plates 4 and four stiffeners 5, and a frame surrounded by four lateral steel plates 4 is welded on the perforated bottom plate 2 with a reserved hole 3 Each outer surface of the frame is welded with a stiffener 5, and the bottom surface of the stiffener 5 is welded with the perforated bottom plate 2.

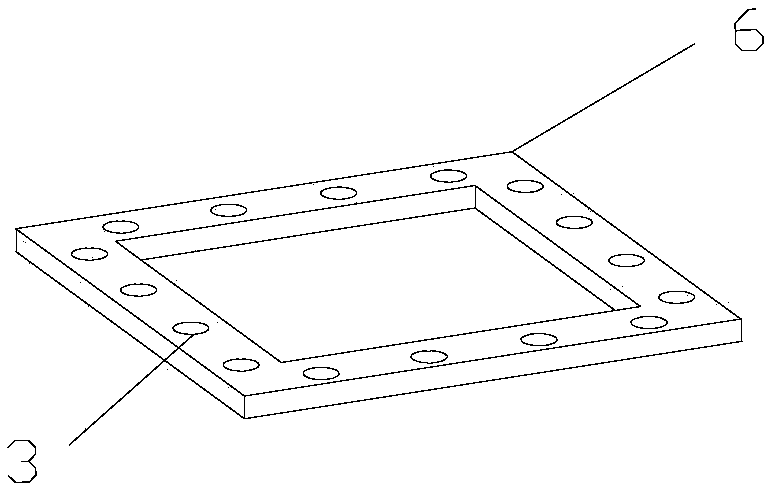

[0040] (2) If figure 2 and Figure 5 As shown, the specific structure and manufacturing process of the bolt rod assembly in the truss foundation are as follows:

[0041] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com