Steel structure fireproof structure and building comprising same

A fireproof structure and steel structure technology, applied in fire prevention, construction, building components and other directions, can solve the problems of low construction efficiency, environmental pollution, the validity period of anticorrosion and fireproof paint, and large amount of wet work on site, and achieves easy handling and hoisting. , Improve the connection efficiency, the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

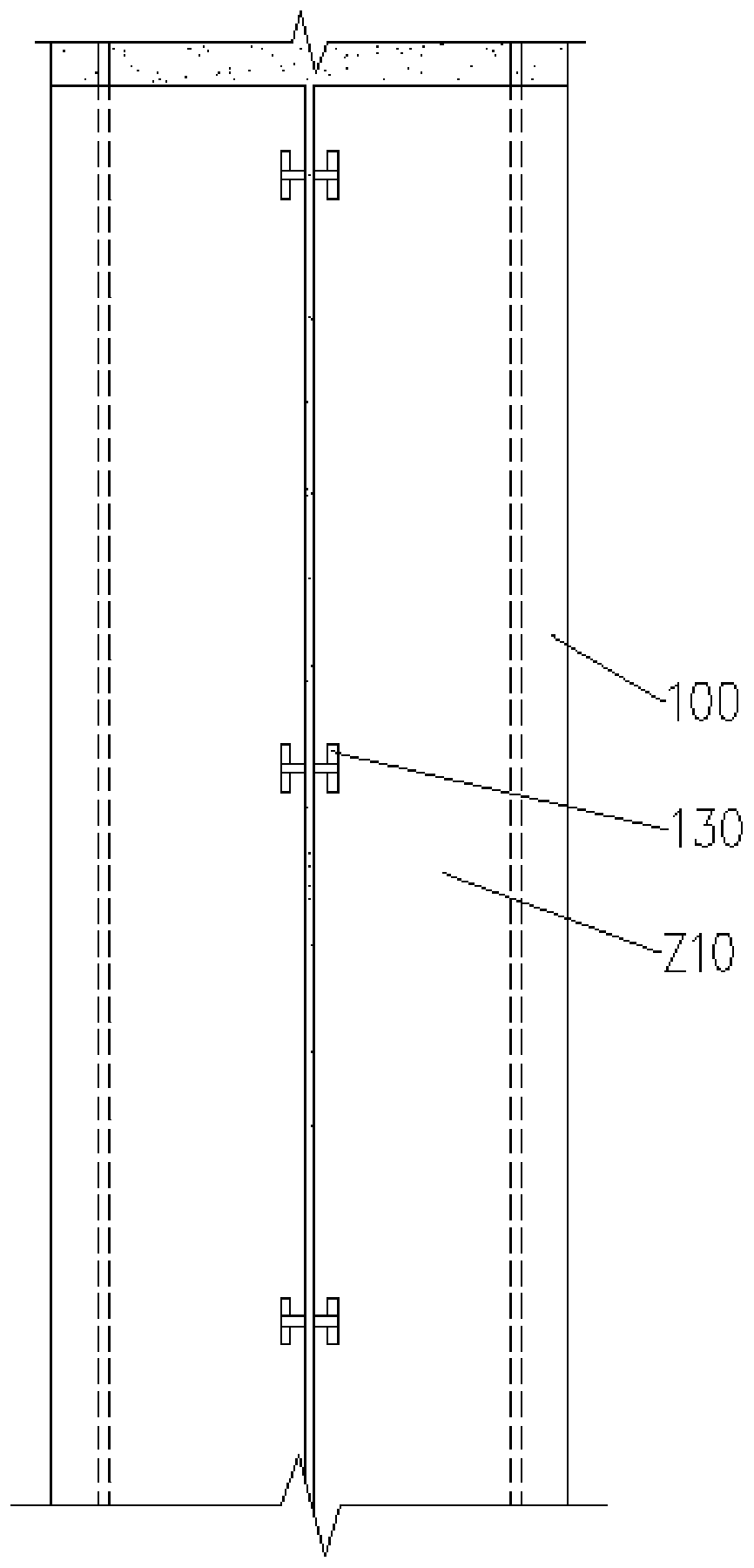

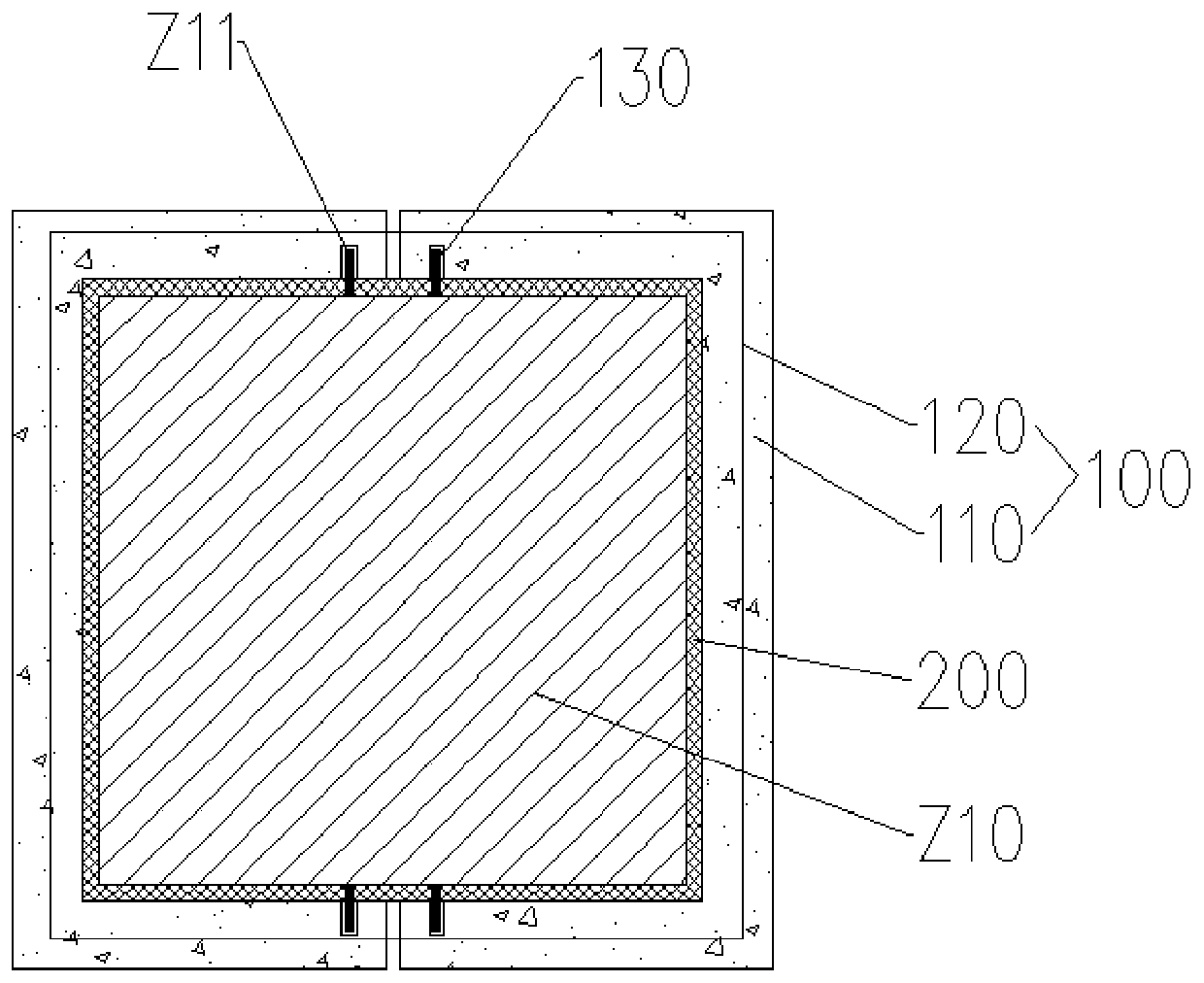

[0069] A steel fireproof structure provided in this embodiment includes: a steel structure and an anti-corrosion and fireproof protective shell 100; Figure 1-2 As shown, the steel structure is a column Z10.

[0070] The anti-corrosion and fire-proof protective shell 100 is a prefabricated panel body 110 made of ultra-high performance concrete, high-performance concrete or high-performance mortar, and the prefabricated panel body 110 is provided with strength and rigidity for enhancing the anti-corrosion and fireproof protective shell 100, and preventing corrosion. The cracked reinforced skeleton 120 of the fire protection shell 100; the anti-corrosion and fire protection shell 100 is coated on the steel structure, and is used for anti-corrosion and fire prevention of the steel structure.

[0071] Wherein, the thickness of the anti-corrosion and fire-proof protective shell 100 is preferably 10mm-50mm.

[0072] The column body 200 may be an H-shaped steel column, a box-shaped ...

Embodiment 2

[0092] The steel structure fireproof structure provided in this embodiment differs from Embodiment 1 in that:

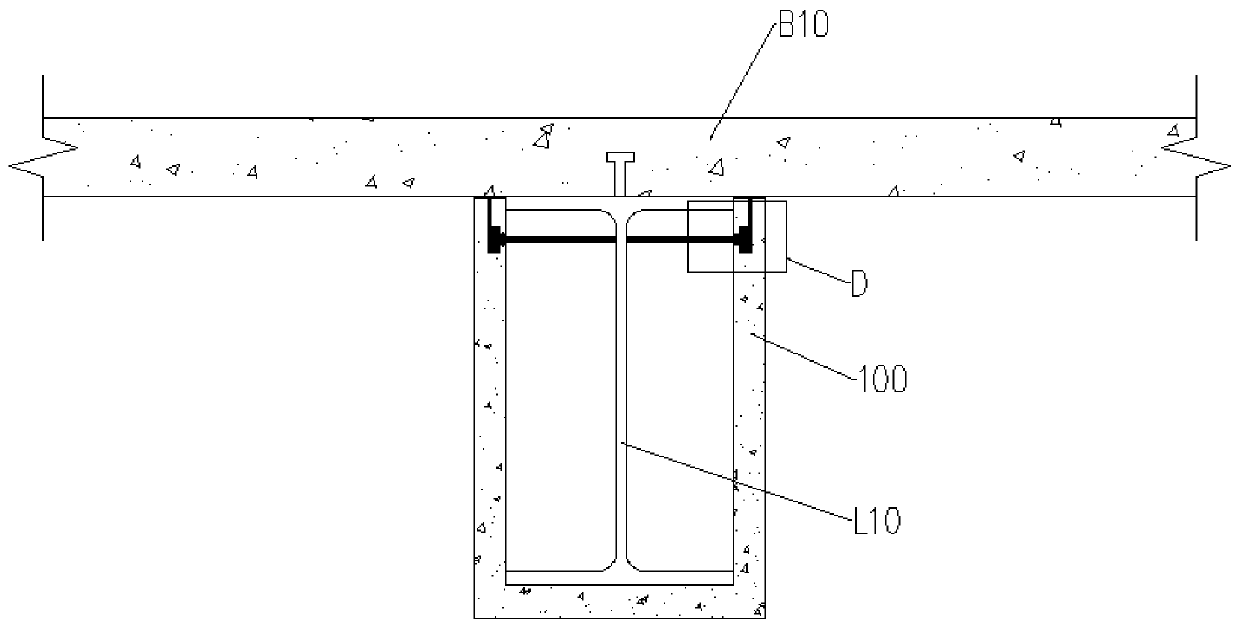

[0093] like Figure 3-5 As shown, the steel structure is steel beam L10. The anti-corrosion and fire-proof protective shell 100 is a prefabricated plate body 110 made of mortar emulsion and nano-material additives. The pre-fabricated plate body 110 is provided with a device for enhancing the strength and rigidity of the anti-corrosion and fire-resistant protective shell 100 and preventing the anti-corrosion and fire-resistant protective shell 100 from cracking. Strengthen the frame 120; the anti-corrosion and fire-proof protective shell 100 is wrapped around the steel beam L10, and is used for the anti-corrosion and fire prevention of the steel beam L10.

[0094] Wherein, the thickness of the anti-corrosion and fire-proof protective shell 100 is preferably 20mm-30mm.

[0095] The anti-corrosion and fire protection shell 100 is a U-shaped piece with a U-shaped cross-s...

Embodiment 3

[0103] The steel structure fireproof structure provided in this embodiment differs from Embodiment 1 in that:

[0104] like Image 6 As shown, the steel structure is a shear wall S4. The anti-corrosion and fireproof protective shell 100 is provided with connection holes, and the shear wall S4 is provided with connection pins S4a (for example, welded with bolts) that fit in the connection holes. The shear wall S4 is covered with two layers of anti-corrosion and fire-proof protective shells 100; in the thickness direction, the innermost anti-corrosion and fire-resistant protective shells are arranged at intervals from the shear wall, and the intervals are filled with insulation materials 210. During construction, the innermost The anti-corrosion and fire-proof protective shell forms a mold, and the insulation material is filled to form an insulation layer outside the shear wall; an interlayer is arranged between two adjacent anti-corrosion and fire-proof protective shells, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com