Fixture for packaging stack array of semiconductor laser

A laser and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of reduced packaging accuracy, reduce errors, improve yield and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

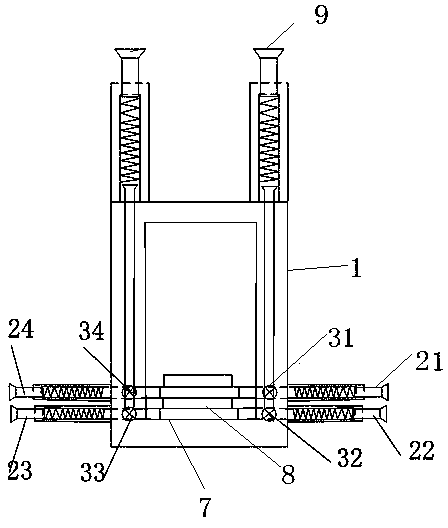

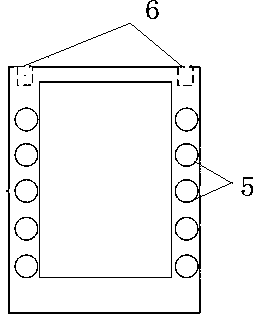

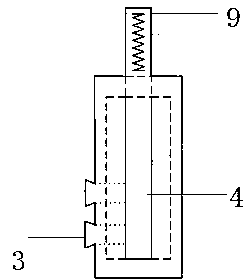

[0026] Attached below Figure 1~8 The present invention will be further described in detail with specific embodiments.

[0027] The present invention is a fixture for fixing and positioning the transitional heat sink of semiconductor laser stack package, including two guide rails fixed on the same fixed plate and a peg for fixing the transitional heat sink placed in the middle of the two guide rails. The studs are installed on the tracks of the two guide rails one by one. There are at least two studs. The studs include a pipe body. Movable screws and thimbles are respectively installed at both ends of the pipe body. The spring located between the screw and the thimble, when the screw is turned, the spring compresses and drives the thimble to move forward. The outer side of the end of the pipe body where the thimble is installed has a protrusion that can hold the peg in the track. The two tracks are fixed on the fixed plate. A transitional heat sink is fixed by two oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com